For purchasing engineers or equipment manufacturers, the price of linear motion guides is one of the most important factors when choosing products. However, the price of guides is far more complex than it appears. Besides model and size, many technical and market factors influence the final cost. This article will systematically analyze the main factors determining the price and provide some purchasing advice to help you obtain the most cost-effective product within your budget.

1. What is an Linear Motion Guide?

Linear motion guides, also known as slide rails, linear guides, or linear guideways, are used to support and guide moving parts to perform reciprocating linear motion in a given direction. With the same volume of moving components, they offer higher rated load and motion accuracy than linear bearings, while also being able to withstand a certain torque load.

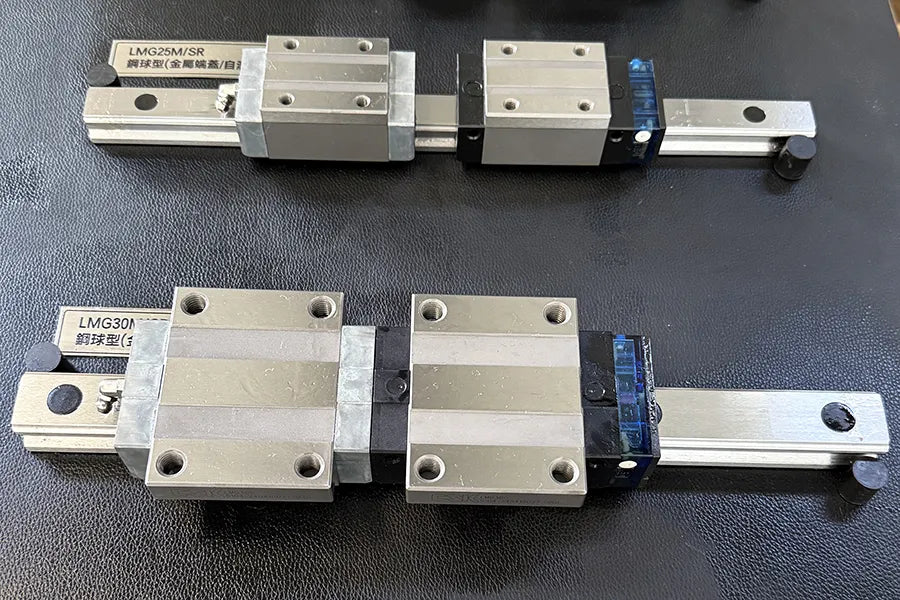

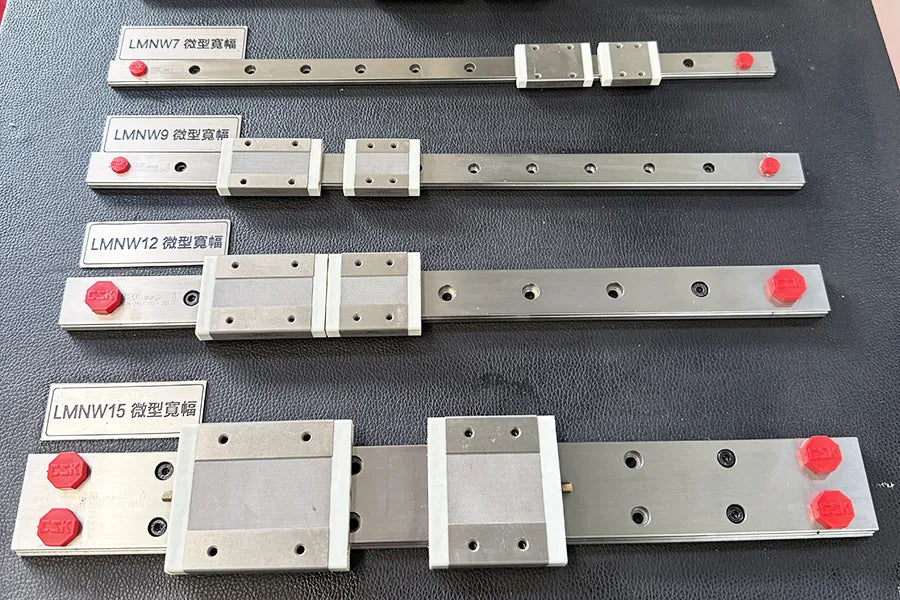

Simkawa linear motion guides can be divided into six categories: LG, LM, LGN, LGW, LMGQ, and LMR, each with its own characteristics. Please refer to the product details page for specific information.

You may also be interested in the following articles:

-

Linear Motion Systems: Pros and Cons of Linear Slides You Should Know

-

Why Linear Guideways Are Essential in Precision Instruments and Measurement Devices

2. Why are Linear Motion Rails So Expensive?

2.1 Guide Rail Types

The main types of linear motion guides are ball guides and roller guides.

- Ball guides have a compact structure and low coefficient of friction, making them less expensive and suitable for light to medium load equipment.

- Roller guides offer higher load-bearing capacity and rigidity, but require higher manufacturing precision, thus their price is relatively higher.

Generally, the average price of roller guides of similar size is 1.3 to 1.8 times that of ball guides.

2.2 Size and Length

The larger the size of the linear rail and slider, the higher the price. Longer guides are typically priced per meter. For example:

- Small guides (e.g., 15 mm wide) cost approximately tens of dollars per meter.

- Medium to large guides (e.g., 30-45 mm wide) cost several hundred dollars per meter.

Special lengths or non-standard sizes will further increase the price.

2.3 Accuracy Grades

Simkawa, a linear motion guide manufacturer, offers a variety of accuracy grades for its guides, ranging from standard (C) to ultra-high accuracy (UP). Increased accuracy inevitably means increased manufacturing and testing costs.

- Standard grade linear guides are primarily used for general positioning operations,

- while high-precision and higher grades are suitable for applications with higher accuracy requirements, such as CNC machine tools or testing equipment.

Each increase in accuracy grade increases the guide cost by 10% to 25%.

2.4 Materials and Coatings

Linear motion guides are typically made of high-carbon steel or stainless steel. Further treatments, such as rust-proof or corrosion-resistant coatings, dust-proof coatings, and high-temperature testing, will increase costs. These treatments include nickel plating, gas nitriding, and black anodizing.

3. How to Choose the Accuracy of a Linear Guide?

The "precision" of linear motion guides primarily refers to the positioning error and parallelism that the guide rail and slider can guarantee during assembly and movement. The precision varies depending on the specific characteristics of different Simkawa guide models.

- LG, LM, and LMGQ linear guides are classified into five precision grades: Standard (N), High (H), Precision (P), Ultra-Precision (SP), and Ultra-High Precision (UP).

- LMR series linear guides are classified into four precision grades: High (H), Precision (P), Ultra-Precision (SP), and Ultra-High Precision (UP).

- LGN and LGW series miniature linear guides are classified into three precision grades: Standard (N), High (H), and Precision (P). Customers can choose the appropriate precision grade based on their equipment's requirements.

When selecting the precision grade of a linear motion guide, the equipment performance and budget should be considered comprehensively:

For general automation equipment, C or H grade is sufficient; for medium-to-high precision equipment, such as CNC machine tools and laser systems, P grade is the mainstream; only for precision measurement or scientific research equipment is SP or UP grade required.

4. Can I Use WD-40 on Linear Rails?

WD-40, often called an industrial all-purpose oil, primarily functions to eliminate friction noise, remove moisture from metal, prevent rust, clean, loosen rusted parts, and dissolve stuck impurities. It can be sprayed on and lubricated wherever there is noise or jamming.

However, it is not recommended for long-term use on linear motion guides, mainly for the following reasons: insufficient lubrication performance, easy evaporation, and washing away the original special grease. However, it can be used during the cleaning process.

5. What are Common Linear Motion Guide Problems?

5.1 What is the maximum allowable operating temperature of a linear guide?

Linear motion guides can generally operate continuously within a temperature range of -20℃ to 80℃, with an instantaneous maximum operating temperature not exceeding 100℃.

5.2 What is the longest possible length of a single linear guide?

The maximum length of a single guide is typically 4 meters. In reality, some manufacturers claim to offer spliced guides of unlimited length. Generally, the end faces of spliced guides are ground and marked accordingly.

5.3 How to correctly select a linear guide, and what factors should be prioritized in guide selection?

Priority factors for linear motion guide selection include: load, safety factor, lifespan, speed, load direction, application, environment, preload, and accuracy grade.

You might like the following articles:

- Linear Motion Rails Installation Guide

- CNC Linear Guide vs Traditional Slide Ways: Which Is Better?

- What Is a Precision Linear Guide and How Does It Work?

5.4 What are the possible causes of noise during linear guide operation?

Speed exceeding the maximum allowable value; Insufficient installation accuracy; Inadequate interface structure; Interface surface structure not meeting manufacturer requirements; Incorrect or insufficient lubrication.