Precision Gear Rack DIN 6 Solutions

DIN 6 gear racks are widely used in many industries and fields due to their high precision, wear resistance and reliability.

Medical Equipment

Construction Engineering

Automation Equipment

Aerosapce

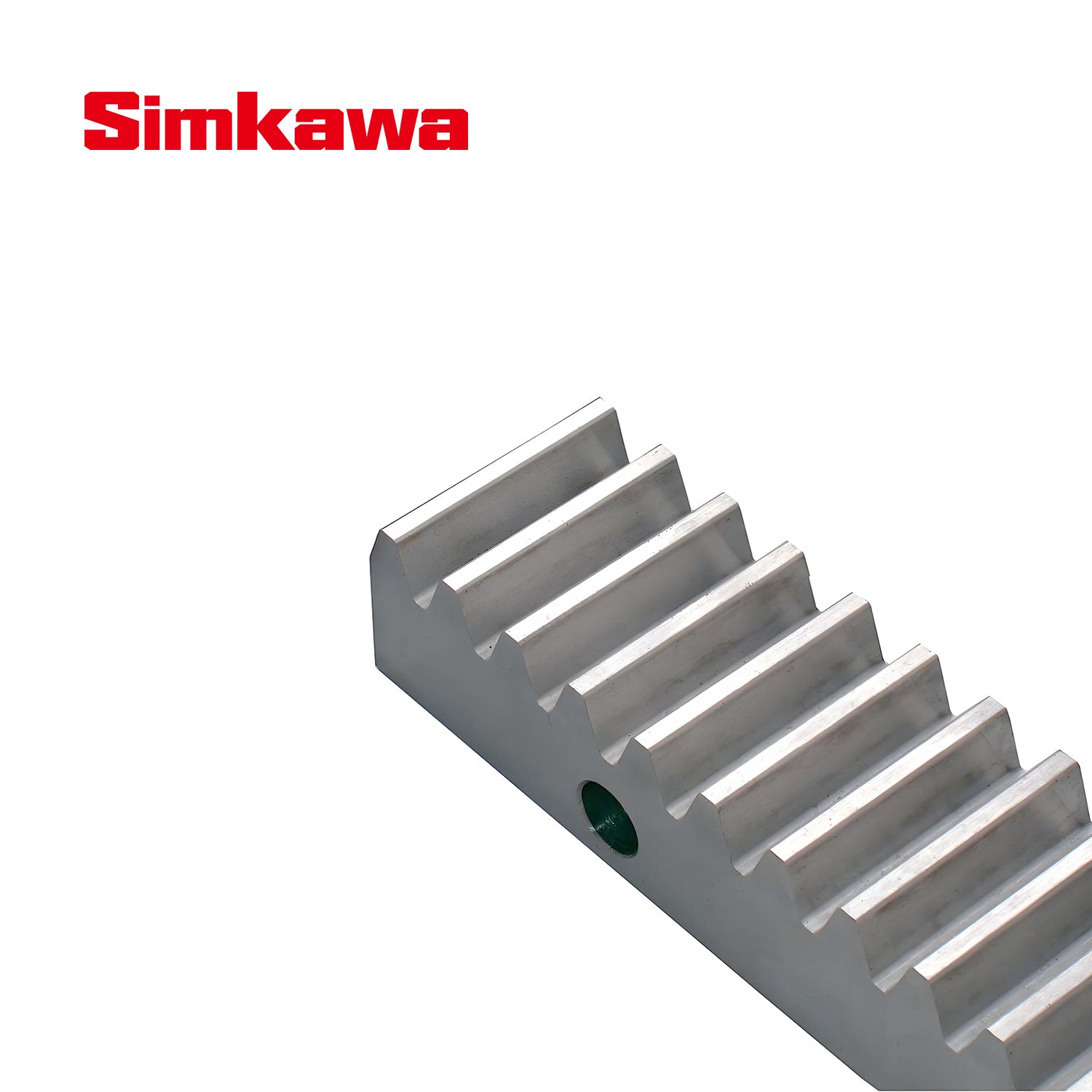

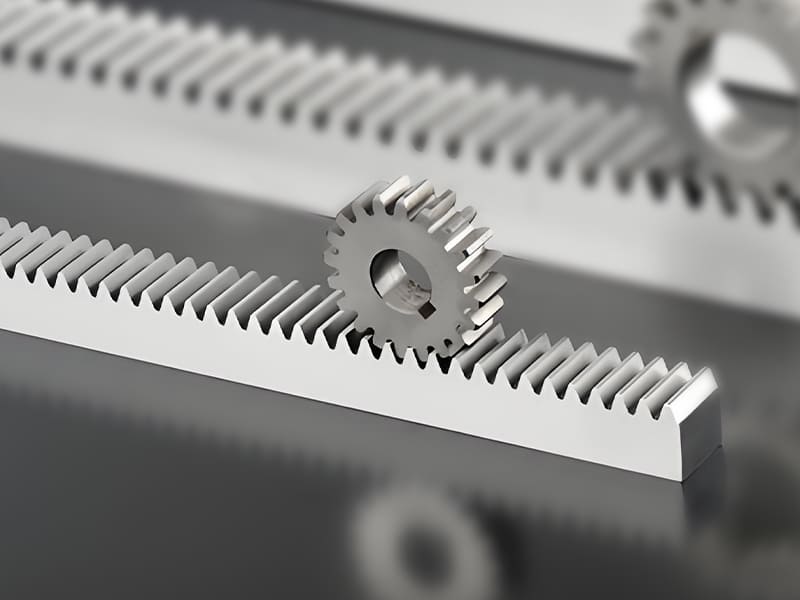

Spur Gear Rack VS. Helical Gear Rack

1. Tooth Design

Spur gear rack: The tooth surface is perpendicular to the axis of the rack, the tooth profile is a straight line, and the force generated during the transmission process is mainly radial.

Helical gear rack: The tooth surface is beveled and the tooth profile is a diagonal line. The force generated during the transmission process is not only radial force, but also axial force.

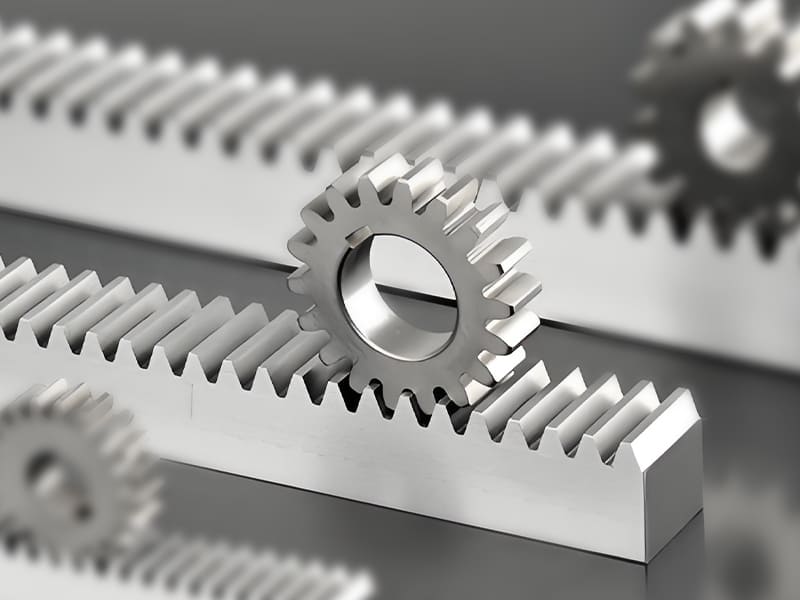

2. Transmission Efficiency

Spur gear rack: Usually has higher transmission efficiency, suitable for low noise and high speed applications.

Helical gear rack: Due to progressive contact, the transmission efficiency is slightly lower, but under high load conditions, helical gears can better disperse pressure and reduce wear, suitable for occasions that require large torque transmission.

3. Noise and Vibration

Spur gear rack: The noise is larger during operation, especially at high speed.

Helical gear rack: Due to progressive contact, the noise is lower and the vibration is smaller during operation.

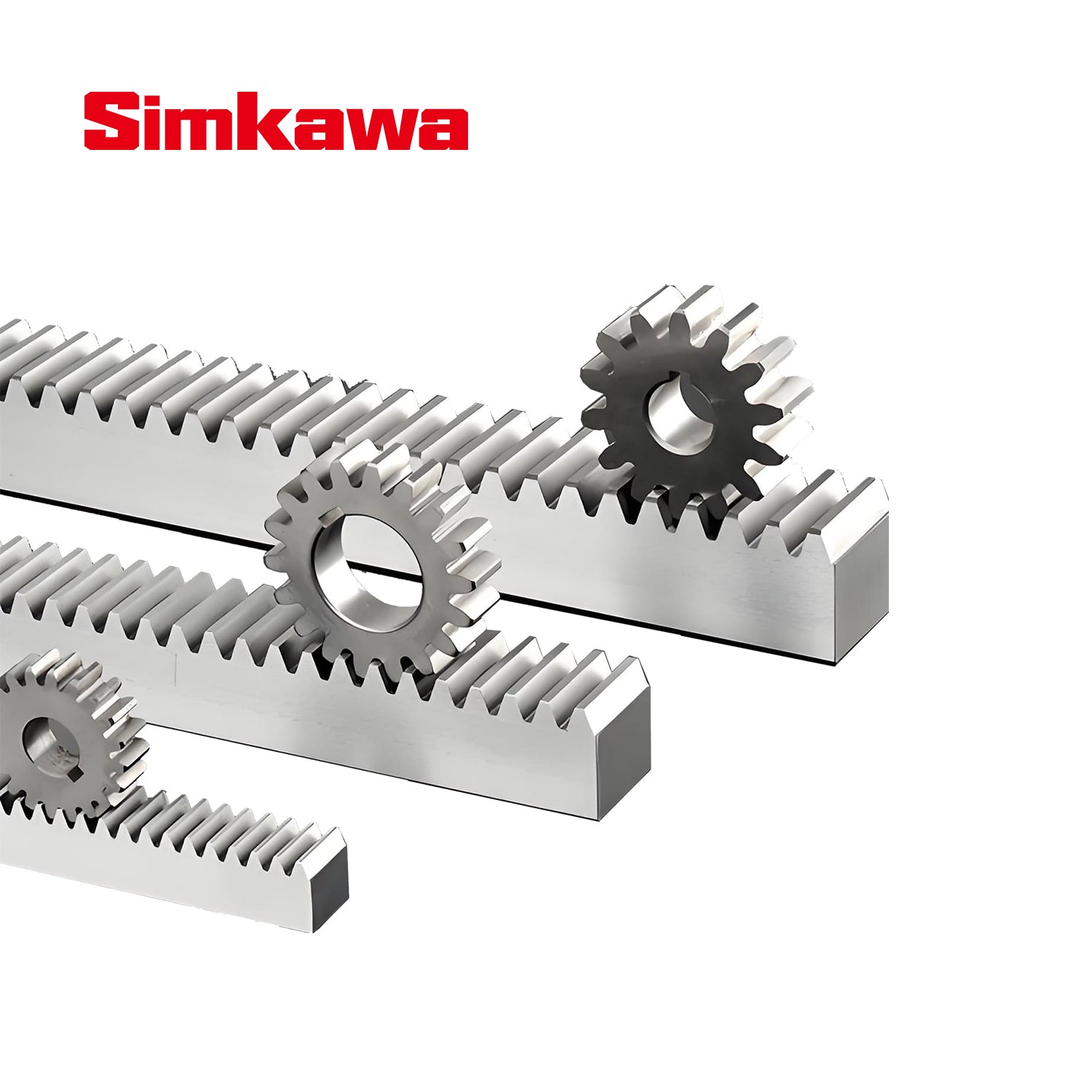

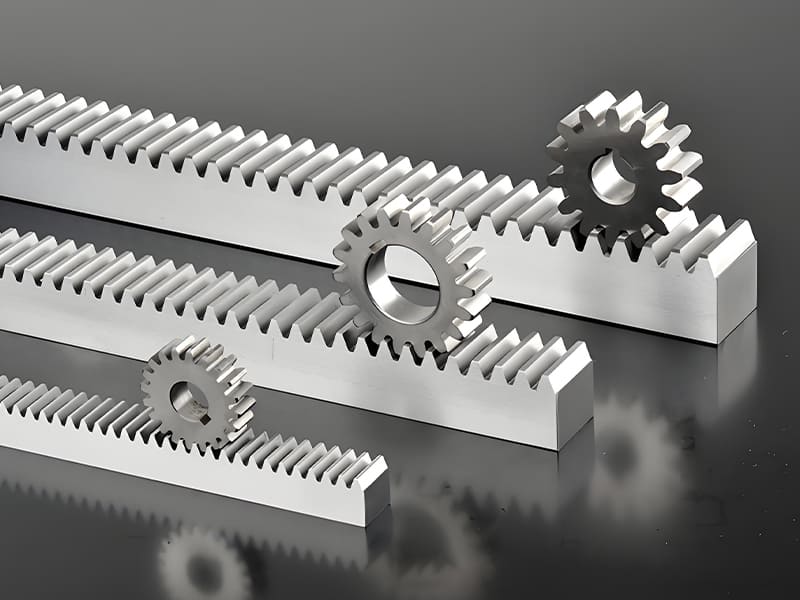

Rack Pinion Gear Advantages

Metal gear racks are widely used in many industries and fields due to their high precision, wear resistance and reliability.

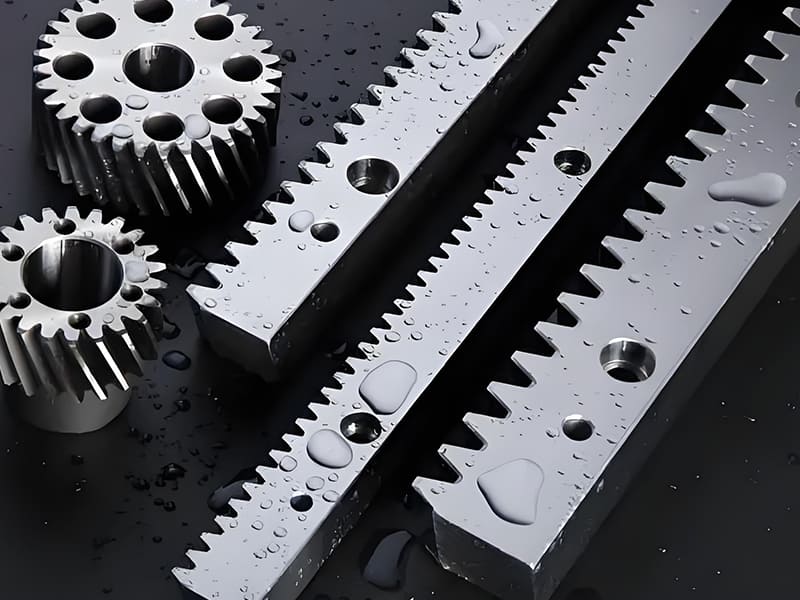

High Precision

Linear racks have strict manufacturing tolerances to ensure accurate tooth shape and pitch, suitable for high-precision applications.

Tempering treatment

After tempering treatment, the hardness and toughness are improved, and the wear resistance and impact resistance are enhanced.

High Transmission Efficiency

The combination of rack and corresponding gear can achieve higher transmission efficiency and reduce energy loss.

Surface Treatment

The steel gear racks are case hardened for increased wear and corrosion resistance.

Accuracy Comparison

Gear Rack DIN 6

It has high precision and is suitable for occasions with high precision requirements, such as CNC machine tools and other high-precision mechanical equipment.

Gear Rack DIN 8

Medium precision, suitable for general mechanical transmission systems such as mechanical equipment and automation equipment.

Gear Rack DIN 9

Relatively low, suitable for applications with lower precision requirements, such as heavy machinery.