My Store

Fine Milling Quality Metal Gear Rack DIN 8 Grade

Our DIN 8 grade metal gear racks offer exceptional precision and durability, ensuring smooth performance under high load and high-speed operating conditions.

Choose options

Metal Gear Rack DIN 8 Features

1. High precision level

Medium and high precision, small tooth profile error, suitable for occasions with certain requirements for transmission accuracy.

2. Smooth transmission

When the rack and gear are meshed, the movement is smooth and the noise is low, which can achieve efficient conversion between linear and rotary motion.

3. Strong load-bearing capacity

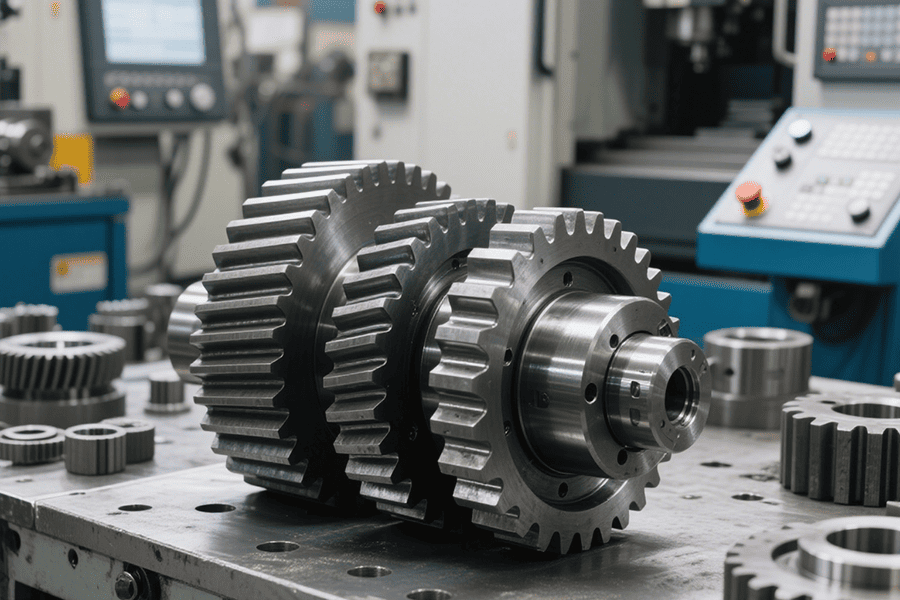

Made of high-quality metal materials, after heat treatment and precision processing, it has high strength and wear resistance and can withstand large loads.

simkawa drive system

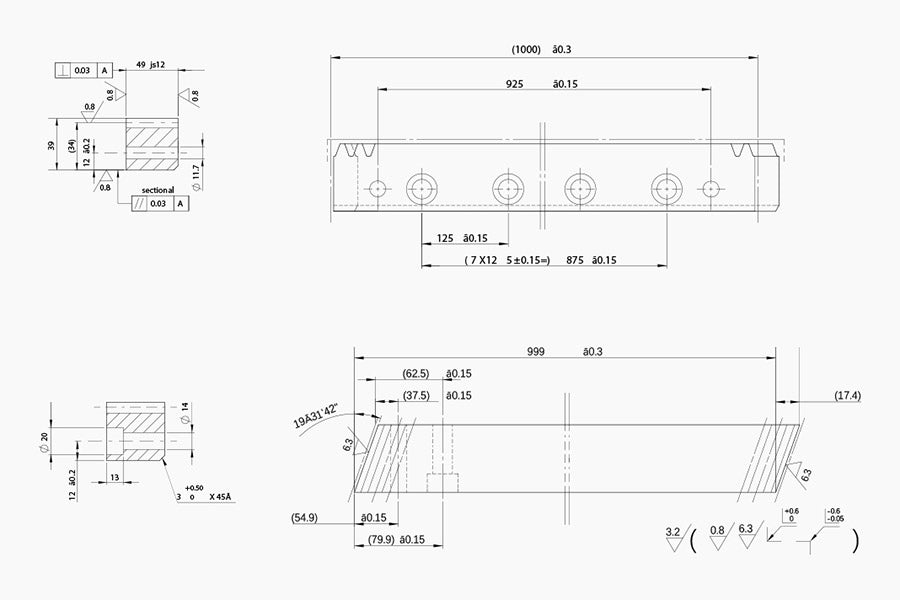

Specification of Steel Gear Rack

Click the download button to get a more detailed specification sheet for rack gear CNC DIN 8.

Parameters of DIN 8 Rack Pinion Gear

| Specification | Value |

| Type | Gear Racks Straight Tooth/Helical Tooth |

| Module | M2/3/4/5/ |

| Gear Grinding Accuracy | German Standard DIN 8 |

| Material | C45 |

| Hardness | HRC24-27 |

| Heat Treatment | Quenching and Tempering |

Surface Treatment of Rack Pinion Gear

1. Galvanizing: Effectively prevents rust and is suitable for wet environments. Improves surface hardness and enhances wear resistance.

2. Blackening: Forms an oxide film to provide rust protection.

Chrome plating: Significantly improves wear resistance and is suitable for high-load applications.

3. Nickel plating: Increases surface hardness and enhances wear resistance.

4. Quenching and tempering: Significantly improves strength and toughness.

How Do Rack Pinion Gears Work?

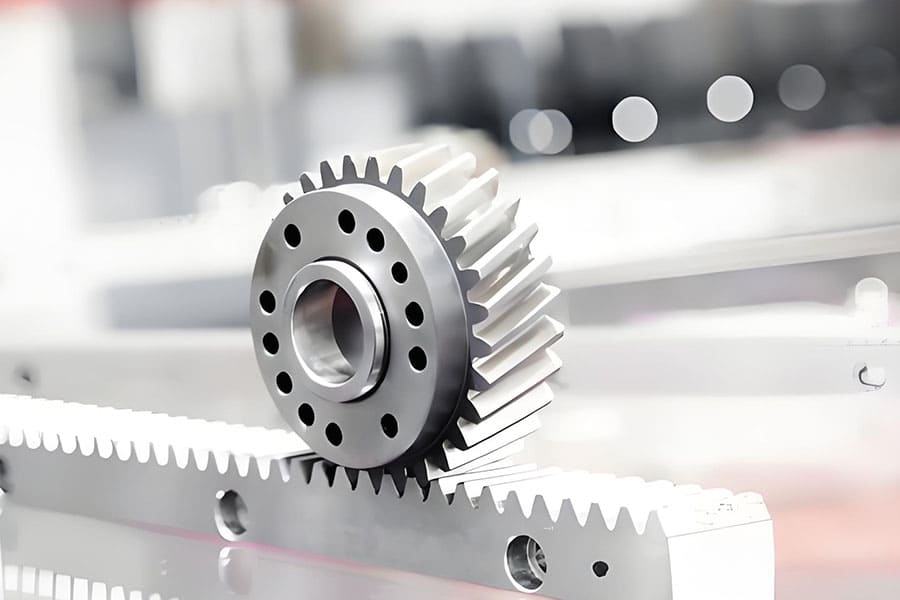

1. The gear is driven by a motor or other power source and starts to rotate. The rotational motion of the gear is the source of power for the rack and pinion system.

2. As the gear rotates, its teeth mesh with the teeth on the rack. As the gear rotates, the rack is pushed, creating linear motion.

3. The rack moves along its length due to the rotation of the gear. This linear motion can be used to move mechanical parts, moving platforms, or other equipment.

We're Here to Help

Provide you with product consultation and technical support!