My Store

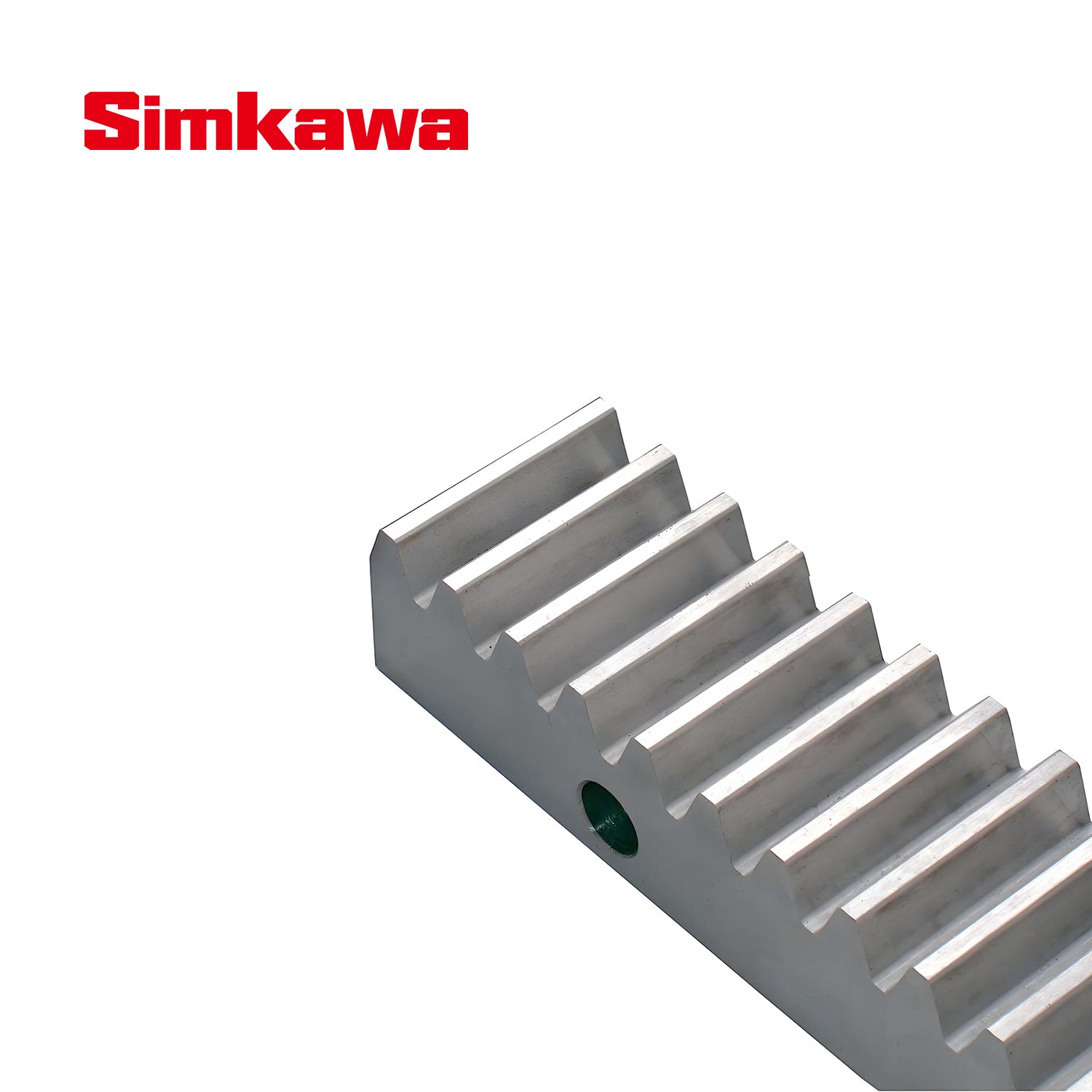

Precision Milled High Frequency Toothed Rack DIN 9

Improve your mechanical performance and choose our high-frequency precision milled toothed racks in accordance with DIN 9. Manufactured using advanced milling technology, this rack ensures accuracy and consistency in each tooth shape for demanding industrial applications.

Choose options

Toothed Rack Din 9 Features

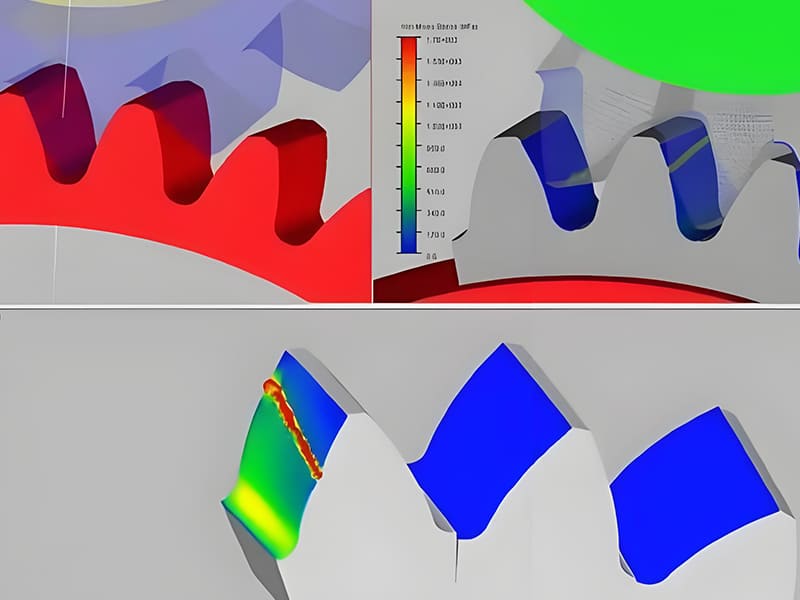

1. DIN 9 racks are of high precision grade, with strict manufacturing tolerances and tooth profile accuracy, ensuring smooth transmission and efficient motion control during use.

2. Due to its precise tooth profile design, the meshing between DIN 9 racks and gears is very smooth, reducing wear and noise, and improving overall work efficiency.

3. Made of high-strength materials, DIN 9 racks can withstand large loads and are suitable for heavy-duty and high-frequency applications.

simkawa drive system

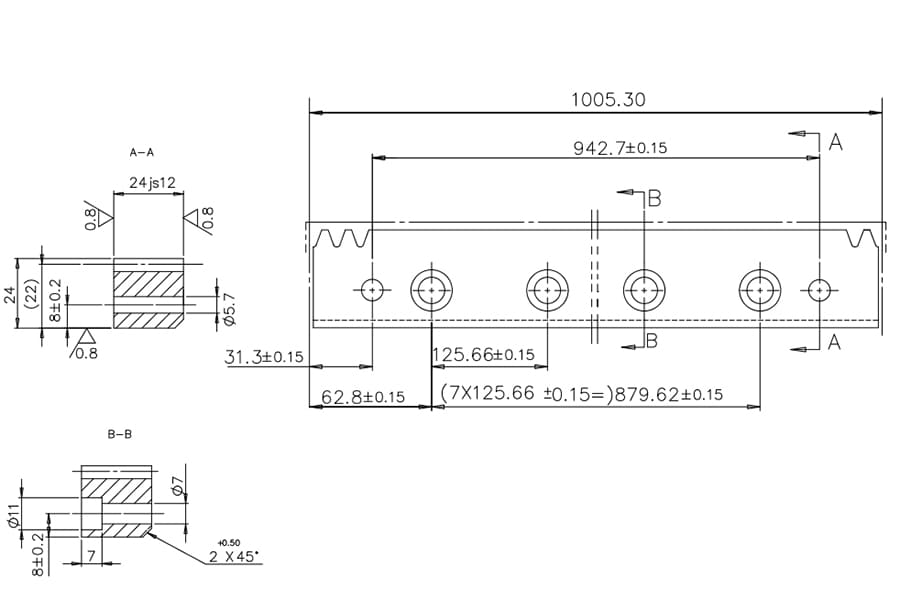

Specification of Toothed Rack DIN 9

Click the download button to get a more detailed specification sheet for ground precision gear rack DIN 9.

Parameters of DIN 9 Toothed Rack

| Specification | Value |

| Type | Gear Racks Straight Tooth/Helical Tooth |

| Module | M2/3/4/5/6 |

| Gear Grinding Accuracy | German Standard DIN 9 |

| Material | C45 |

| Hardness | HRC50-55 |

| Heat Treatment | High Frequency Quenching of Teeth |

| Color | Black, Zinc plated, etc. |

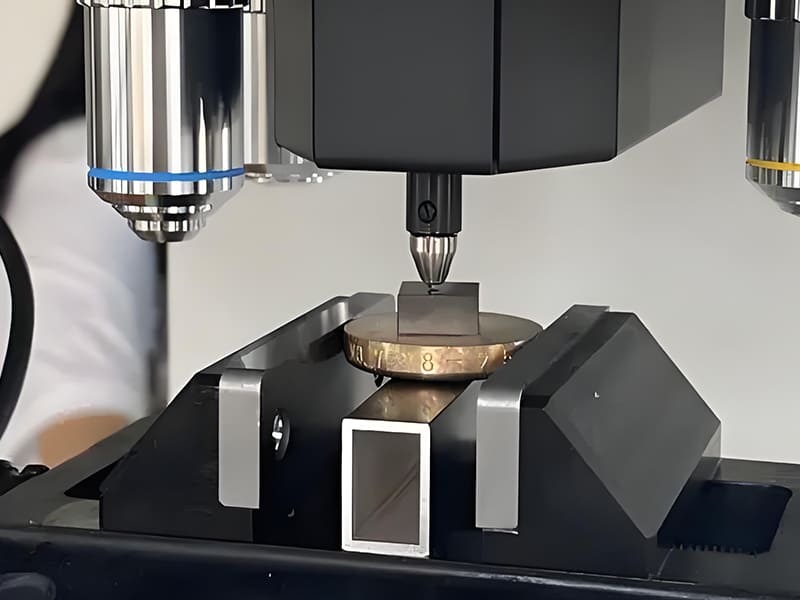

Quality Testing

Geometric Measurement

Use a caliper, micrometer, or other tool to measure the length, width, and height of the rack to ensure it meets design specifications.

Load Testing

The racks are load tested under actual operating conditions to assess their load-bearing capacity and stability.

Hardness Test

Use Rockwell hardness tester or Vickers hardness tester to test the hardness of the rack to ensure its wear resistance.

Wear Resistance Test

The wear resistance of the rack is evaluated by friction test or wear test.

We're Here to Help

Provide you with product consultation and technical support!