Simkawa

LMR Linear Roller Guides

The LMR series linear guides use rollers instead of steel balls, changing from point to line contact for greater load capacity.

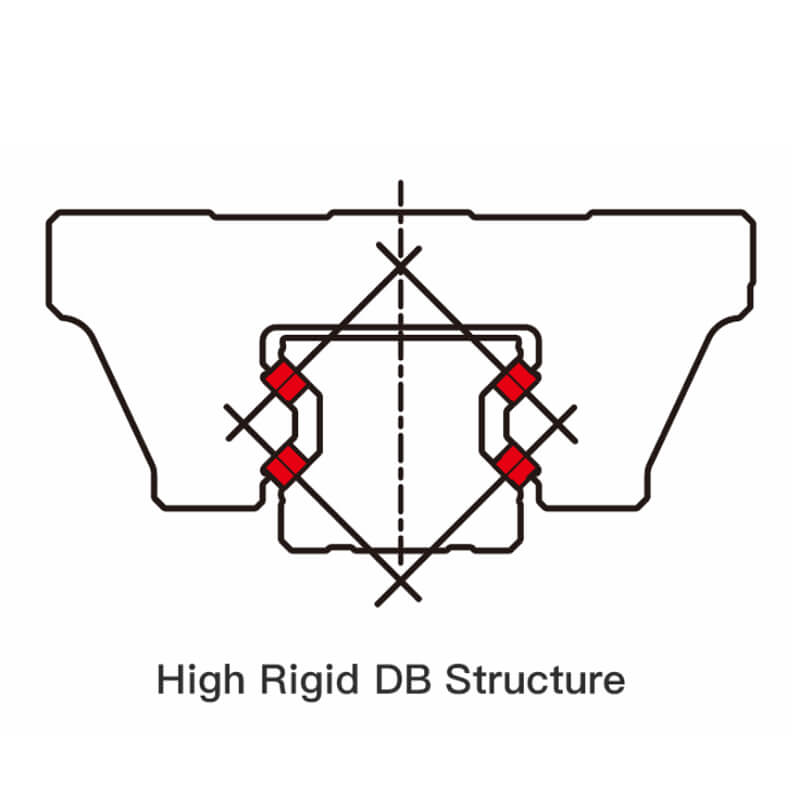

With minimal elastic deformation under heavy loads, the 45° (DB) contact angle design ensures high rigidity and supports forces from all four directions: radial, reverse radial, and lateral.

Choose options

Linear Roller Guides Features

- Ultra-high rigidity and heavy-duty load capacity

- DB design with four-way equal load capacity

- Ultra-high precision, available in grades H, P, SP, and UP

- Interchangeable sliders

- Fully sealed and available in a variety of configurations

- Manufactured in accordance with international standards for dimensions and performance parameters.

simkawa linear guide

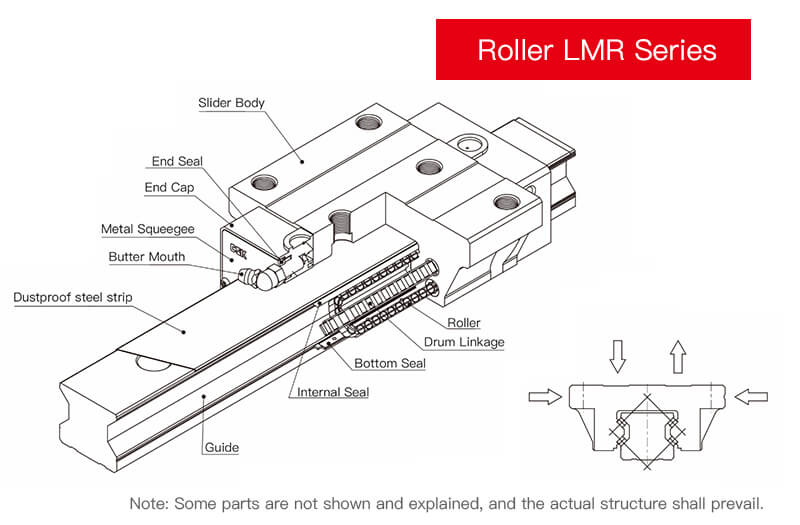

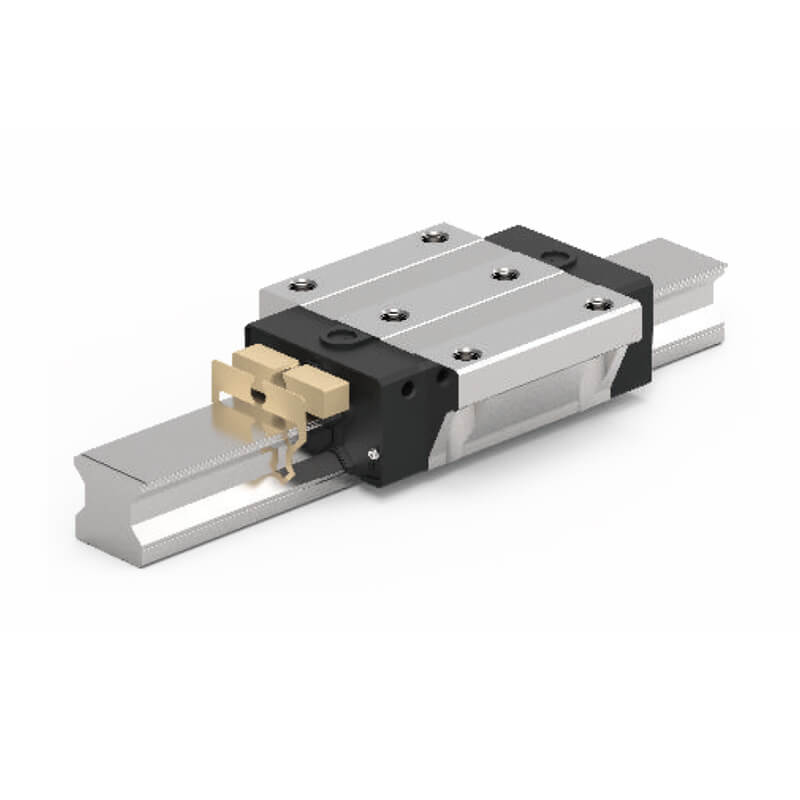

Structures of Roller Guide Rails

Rolling circulation system: slider, slide rail, end cover, steel ball, steel ball retainer

Lubrication system: oil nozzle, oil pipe joint

Dust protection system: oil scraper, bottom dust seal, slide rail bolt cover, metal scraper

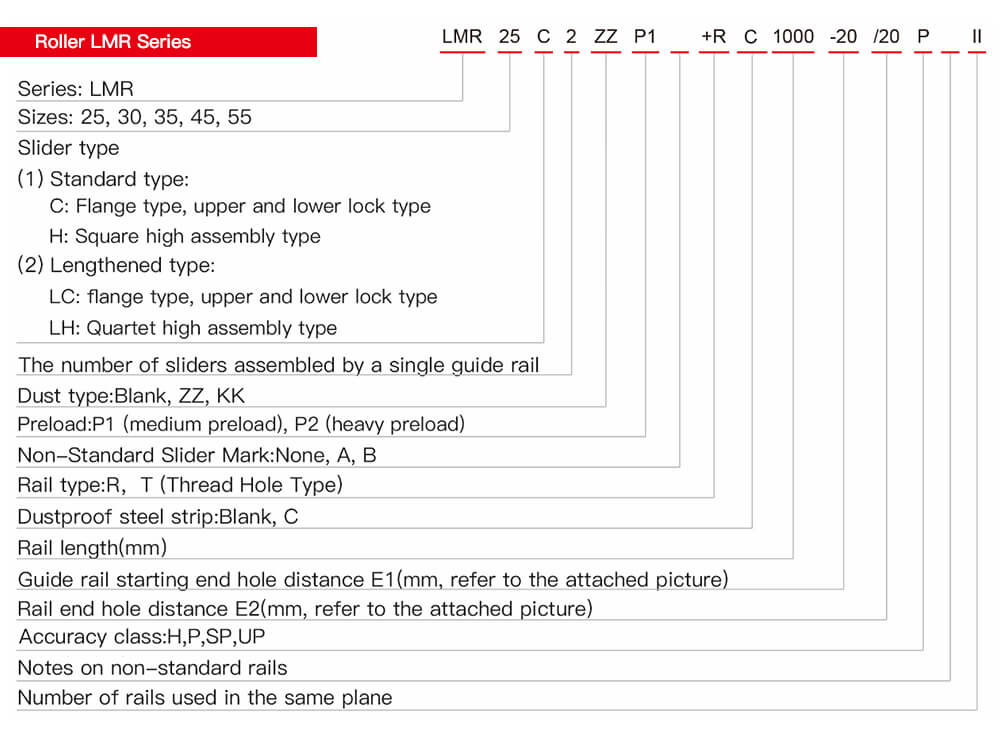

Specifications

Linear Roller Rail Systems Set

Roller guide rails are usually composed of guide rails and sliders. Common specifications and models are as follows.

Product Advantages

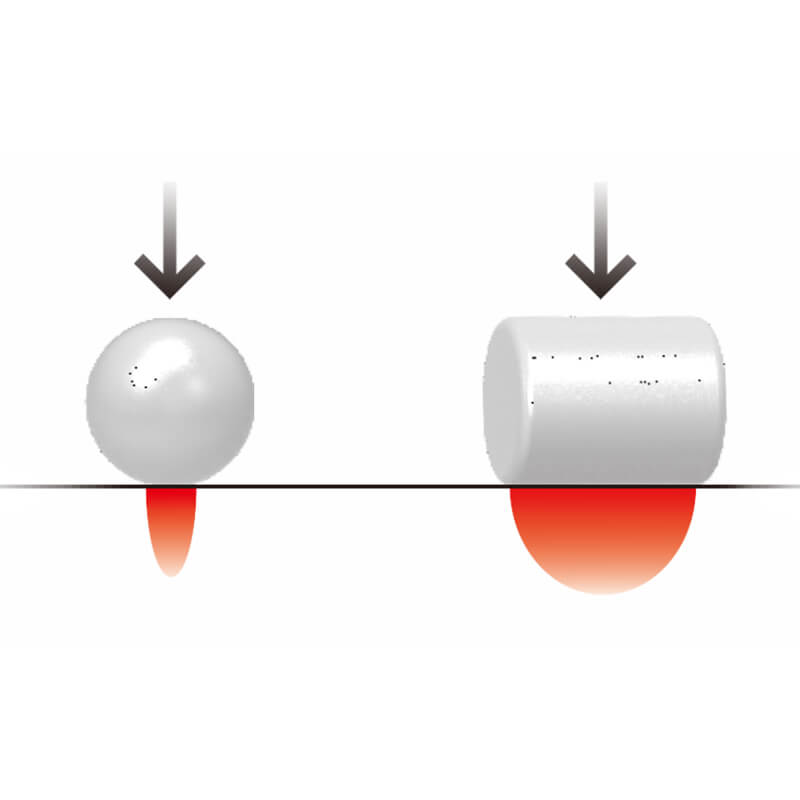

Ultra-High Load Capacity

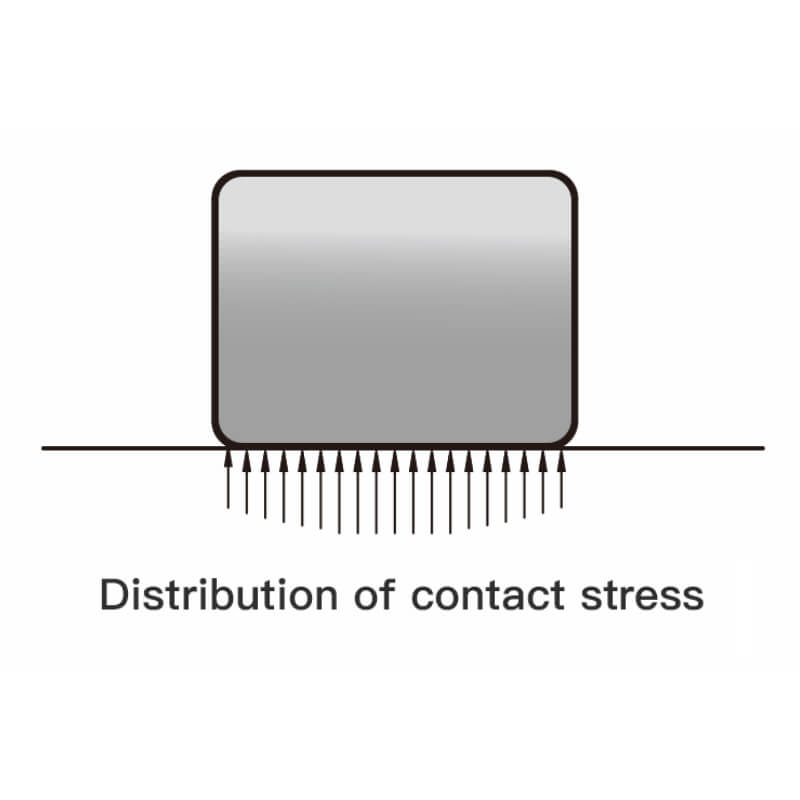

Rollers replace steel balls as rolling elements, increasing contact from point to line contact, thereby increasing the contact area and significantly improving load capacity.

Ultra-High Rigidity

Using modern digital technology to analyze and optimize the roller contact position, we design the rollers to maximize their torque load resistance.

Motion Precision

Exclusively developed fine-grained control of the roller contact surface ensures smooth rolling motion and ultimately achieves ideal travel accuracy.

Innovative Lubrication

The slider has a built-in self-lubricating module that uses engineered fibers to guide the lubricant to the guide rail surface. Roller guides only require a very thin oil film for lubrication.

Advantages

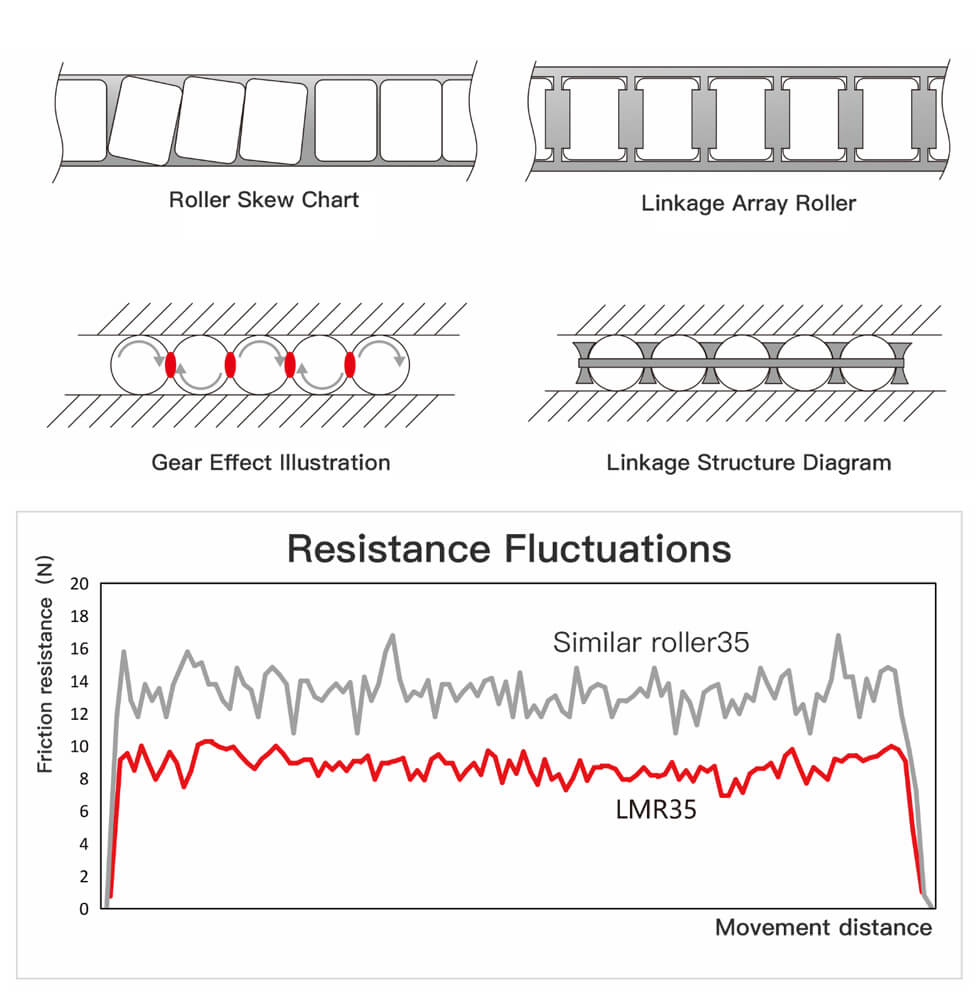

Smooth Motion

Each component is designed to be optimized, and each roller is evenly arranged through the roller linkage to solve the unique rolling skew problem of rollers, eliminate the gear effect of the rolling elements, and minimize rolling resistance, thereby achieving the best running quality.

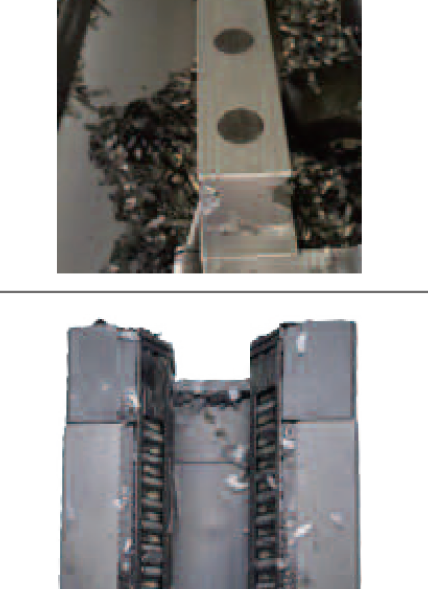

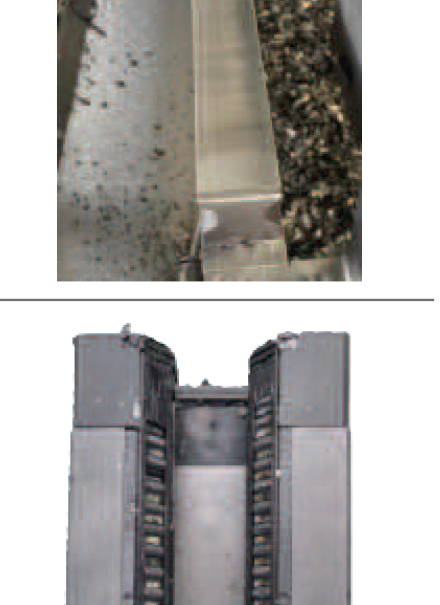

Dust resistance test

To meet the demands of harsh environments, the slider ends are covered with metal scrapers as a first layer of protection, effectively preventing damage to the sealing plate from metal debris. The rails are protected by a full range of steel strips, which not only improves assembly efficiency but also effectively prevents foreign matter from entering the track after damage caused by traditional bolt covers.

Tested Product: LMR30H1ZZP1 + R1000-20/20H

Speed: 1m/s

Environment: Covered with aluminum shavings

Distance: 10,000km

Results: Aluminum shavings were found inside the bolt cover slider. No abnormalities were found inside the dustproof steel belt slider.

Use bolt covers

Use steel rail dust protection strips

We're Here to Help

Provide you with product consultation and technical support!