Simkawa

DFA Servo Ball Screw

DFA servo ball screw delivers precise, low-backlash motion for CNC machines and automation systems. Ideal for high-speed, high-load applications.

Choose options

DFA Servo Ball Screw Features

- Highly responsive design

The DFA series is optimized for servo drive systems, enabling fast start and stop and high-frequency reciprocating motion.

- High precision, low backlash

The preload structure between the lead screw and the nut eliminates axial clearance and ensures positioning accuracy and repeatability.

- Adaptable servo motor system

Strong compatibility with mainstream servo motors, high transmission efficiency, and closed-loop control.

- High speed and high load capacity

Strong structural rigidity, wide range of lead options, support high-speed feed and high-load conditions.

simkawa drive system

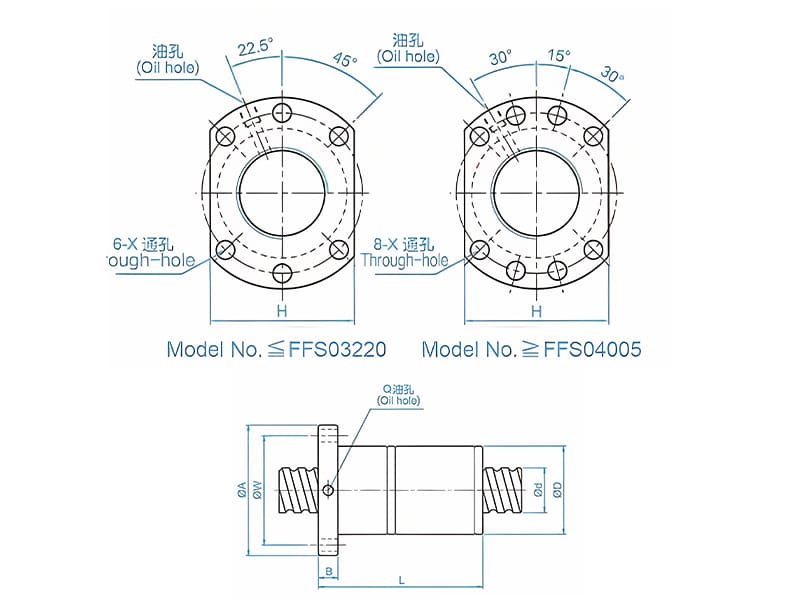

Specifications of DFA Servo Ball Screw

Contact us by clicking the button below to get the latest quote for DFA series ball screw drive system.

Manufacturing Process

Milling

The milling process is a one-step process of rolling the thread into a thread shape by extrusion (plastic deformation) between two rollers. It has high processing efficiency, fast delivery and low price. Generally, it can process lead screws with precision of C7 and C10. It is used for equipment with general precision.

Manufacturing process

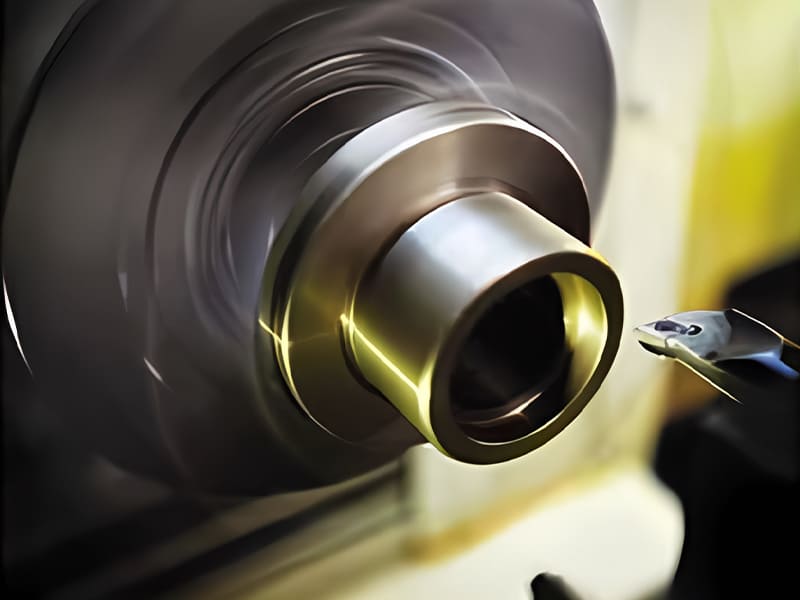

Grinding

The ball screw DFA series is ground by a high-precision thread grinder. Generally, it can process C5, C3, C1 precision screws. It is suitable for precision CNC equipment, such as CNC milling machines, CNC lathes, machining centers, etc.

Servo Ball Screw Life

The life of a ball screw is determined by the basic dynamic load rating.

- Relationship between temperature and life

For the temperature of the ball bearing screw, when it is higher than 100 degrees Celsius, the basic rated dynamic load decreases as the temperature decreases. - Relationship between hardness and life

Generally, for the hardness of the screw, when it is lower than HRC58, the basic rated dynamic load should decrease as the hardness decreases.

We're Here to Help

Provide you with product consultation and technical support!