My Store

High Precision CNC Pinion Gear Rack DIN 6S Grade

Simkawa precision DIN 6S precision rack and pinion, with high-precision and high-rigidity racks with ground tooth surfaces and sides, is widely used in high-speed woodworking machinery, injection molding robots, high-speed machines and general automation industries.

Choose options

CNC Rack and Pinion Din 6S Features

1. High precision, DIN 6S grade gear rack adopts strict manufacturing standards to ensure high consistency of tooth shape and pitch, providing precise transmission performance.

2. DIN 6S grade gear rack can achieve smooth movement, reduce friction and noise during operation, and improve the overall performance of the equipment.

3. The use of high-quality materials and advanced processing technology makes DIN 6S gear rack have good wear resistance, can maintain stable performance in long-term use, and extend the service life.

4. DIN 6S grade gear rack is widely used in automation equipment, machine tools, robots and other fields, suitable for various occasions requiring precision linear motion.

simkawa drive system

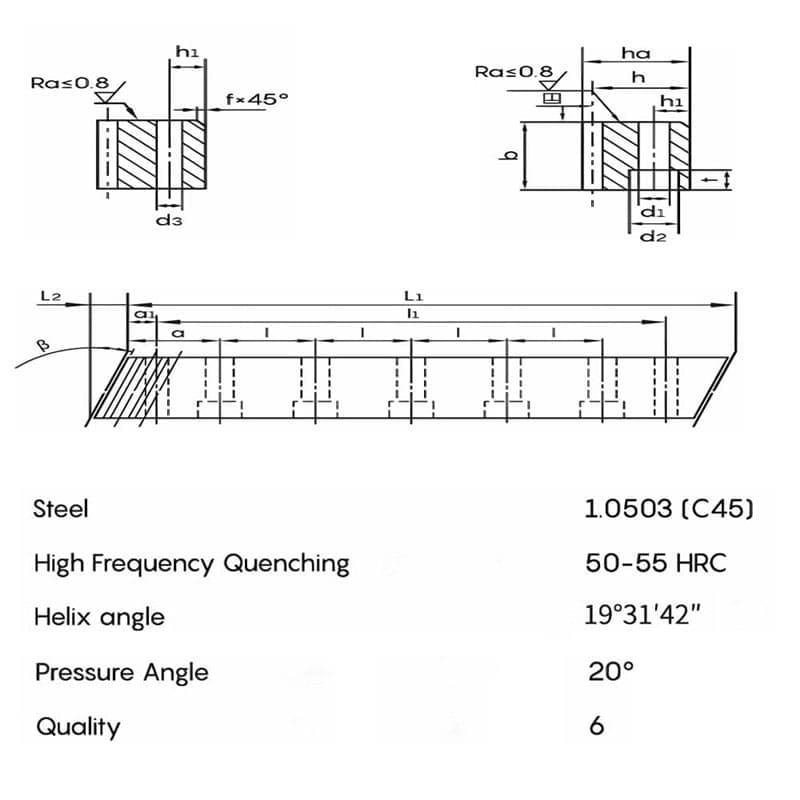

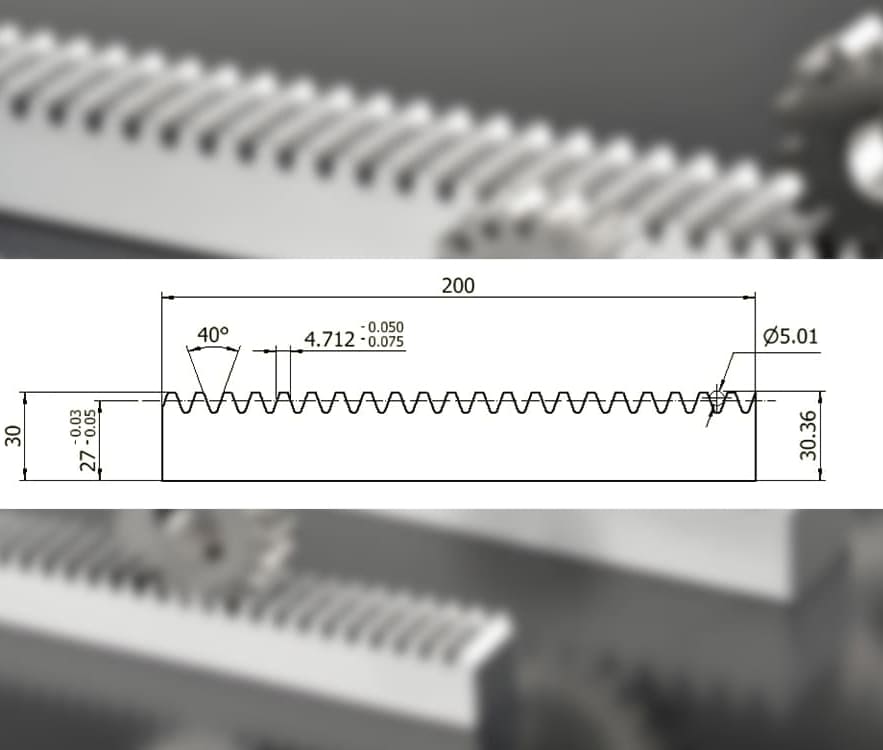

Specification of Industrial Rack and Pinion

Click the download button to get a more detailed specification sheet for ground precision gear rack DIN 6S.

Parameters of DIN6S Gear Rack

| Specification | Value |

| Type | Gear Racks Straight Tooth/Helical Tooth |

| Module | M 1.5/2/3/4/5/6/8 |

| Gear Grinding Accuracy | German Standard DIN 6S |

| Material | C45 |

| Hardness | HRC50-55 |

| Heat Treatment | High Frequency Quenching of Teeth |

| Pressure Angle | 20° |

Precision Grade

The CNC pinion rack is precision ground to meet the German DIN 6A standard, ensuring the consistency of the rack pitch and extremely small allowable deviation. This high-precision design ensures smooth operation during movement and is very suitable for applications that require extremely high precision and reliability. DIN 6A standard racks perform well in mechanical transmission systems and meet various high-end industrial needs.

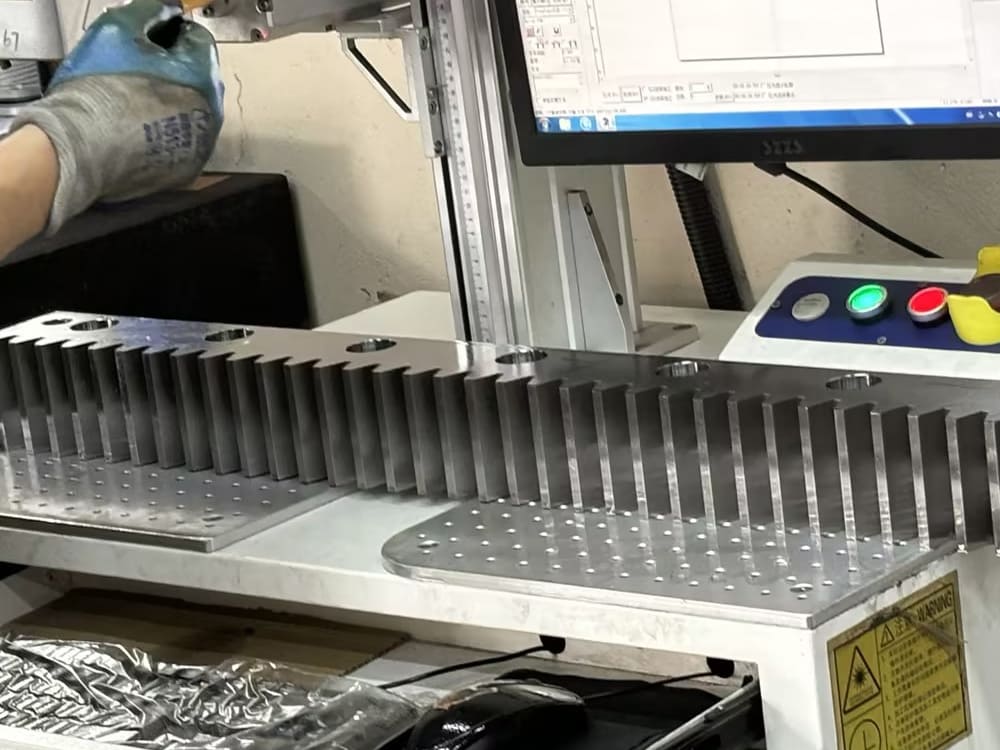

CNC Pinion Rack Pressure Test

Precision rack and pinion stress testing is an important method for evaluating the performance of a rack under load. Stress testing can identify potential failures of the rack under high load conditions, ensuring that no accidents will occur in actual applications and ensuring the safety of operators.

We're Here to Help

Provide you with product consultation and technical support!