My Store

LG Heavy Duty Linear Guide

LG heavy duty guide rails system has improved load and rigidity capabilities compared to other linear guides. It has four-way load characteristics and automatic centering function, and is designed for high-load and high-precision applications.

Choose options

Heavy Duty Linear Rails Features

1. Ultra-heavy-duty precision linear guideway with optimized structural design

2. Equal load in four directions

3. Automatic self-aligning, can absorb assembly errors of mounting surface, and obtain high precision

4. Slideway and slider are interchangeable, and can be ordered as needed.

simkawa linear guide

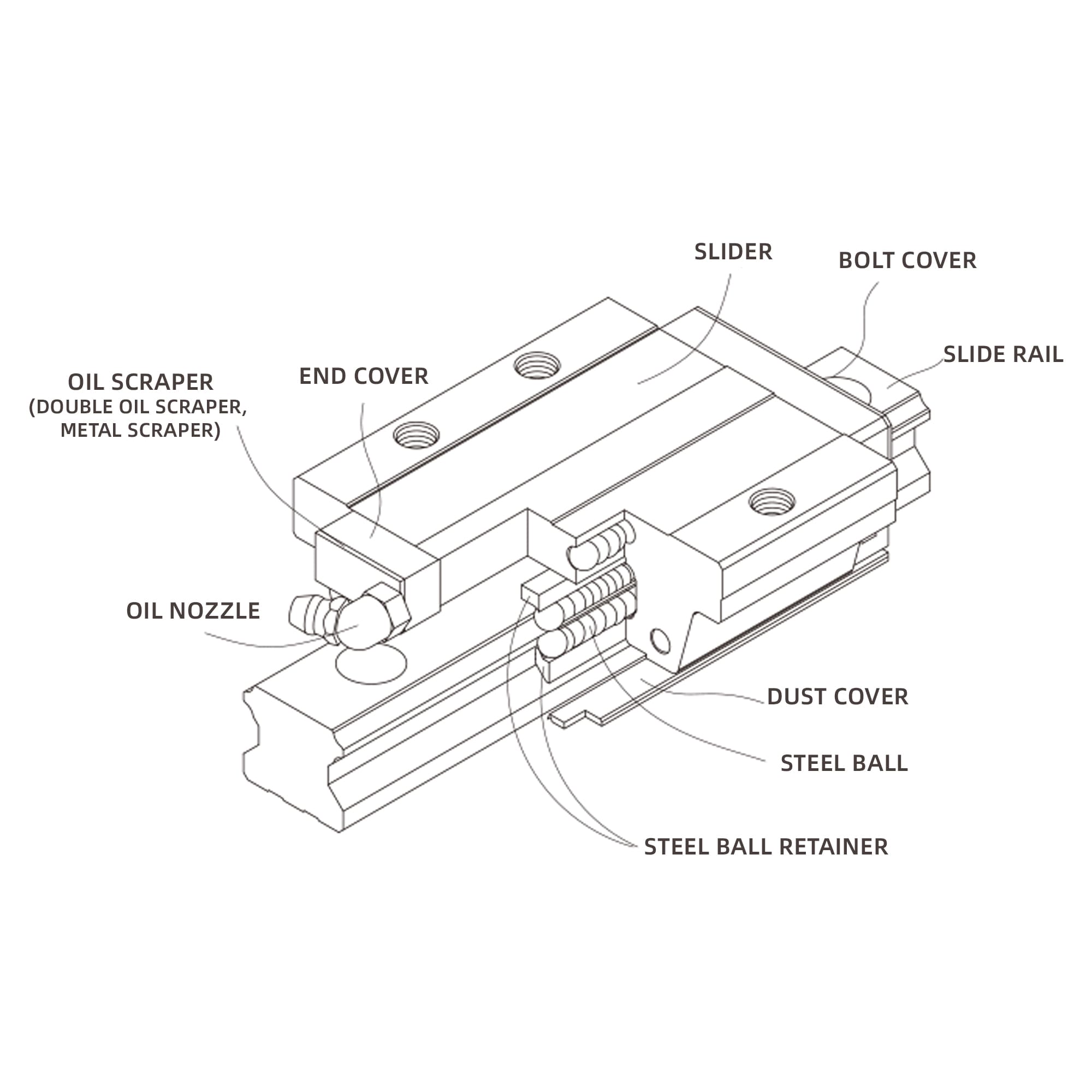

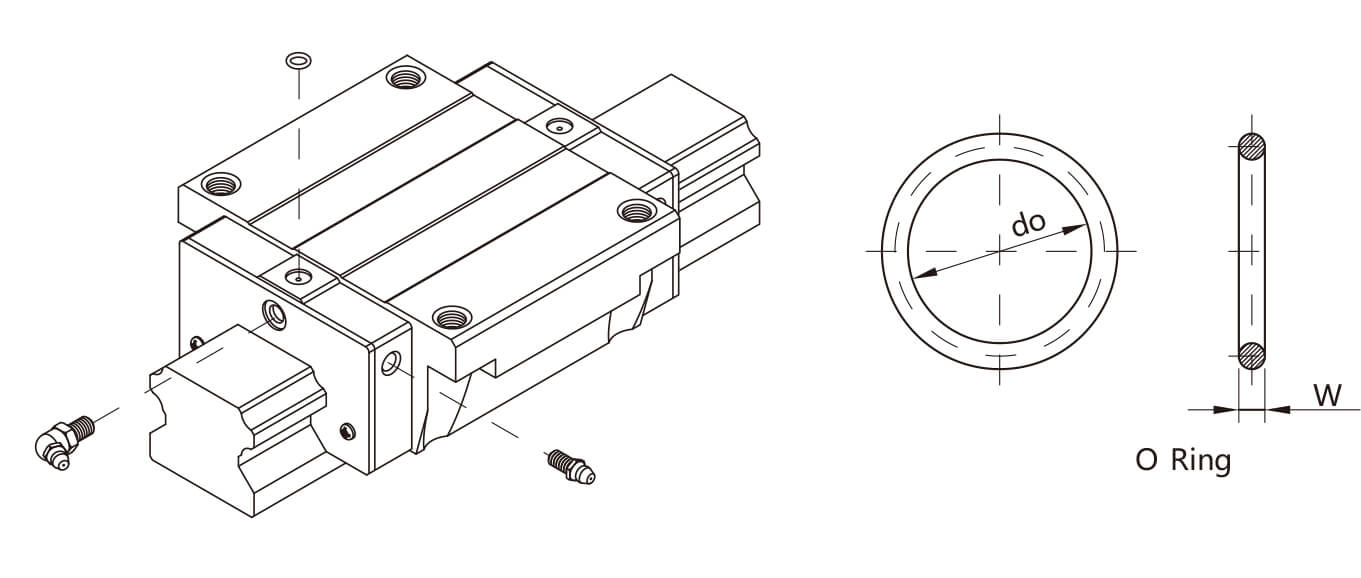

Structures of Linear Slides Heavy Duty

Rolling circulation system: slider, slide rail, end cover, steel ball, steel ball retainer

Lubrication system: oil nozzle, oil pipe joint

Dust protection system: oil scraper, bottom dust seal, slide rail bolt cover, metal scraper

Specifications

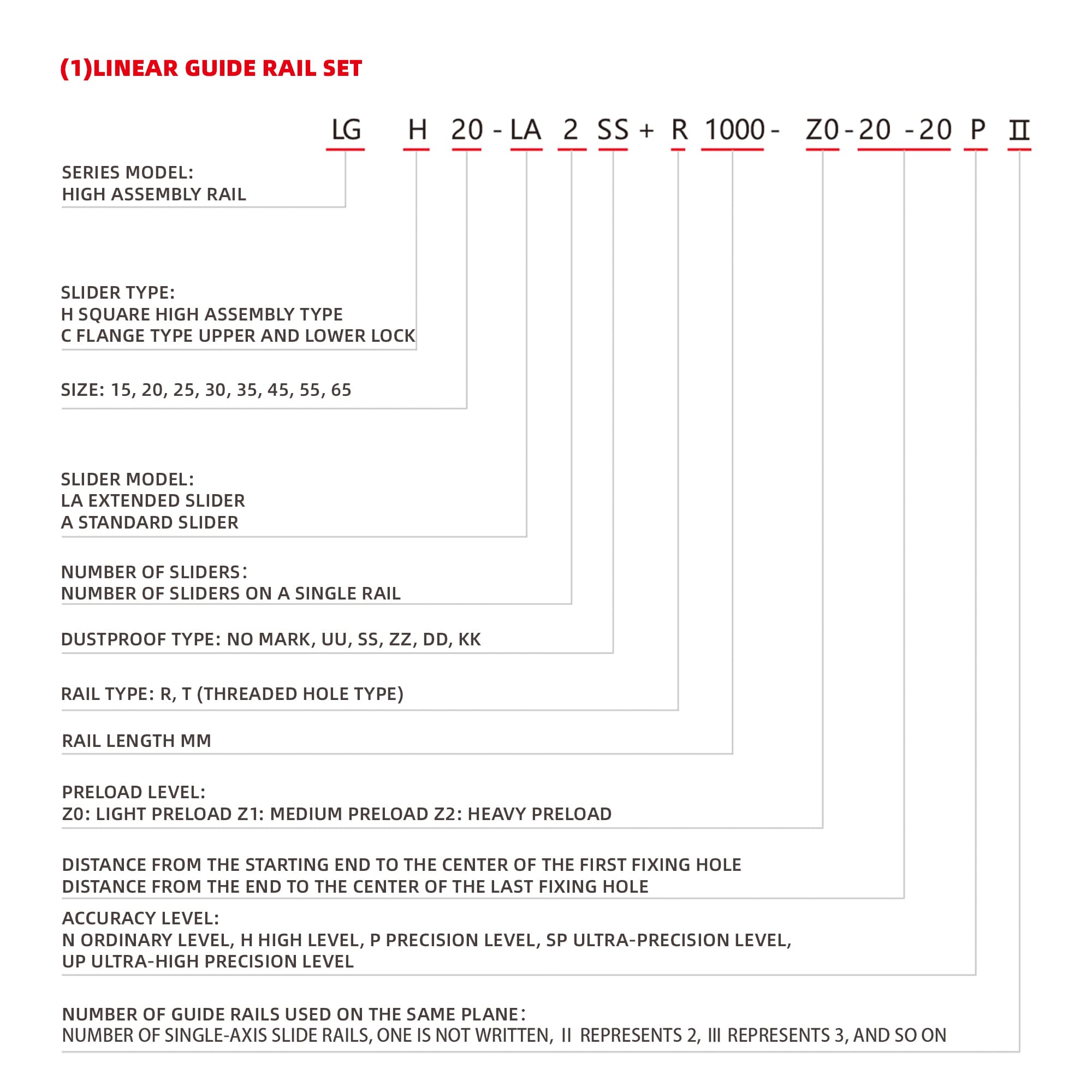

Linear Guide Rail Set

Linear guide assemblies are usually composed of guide rails and sliders. Common specifications and models are as follows.

Specifications

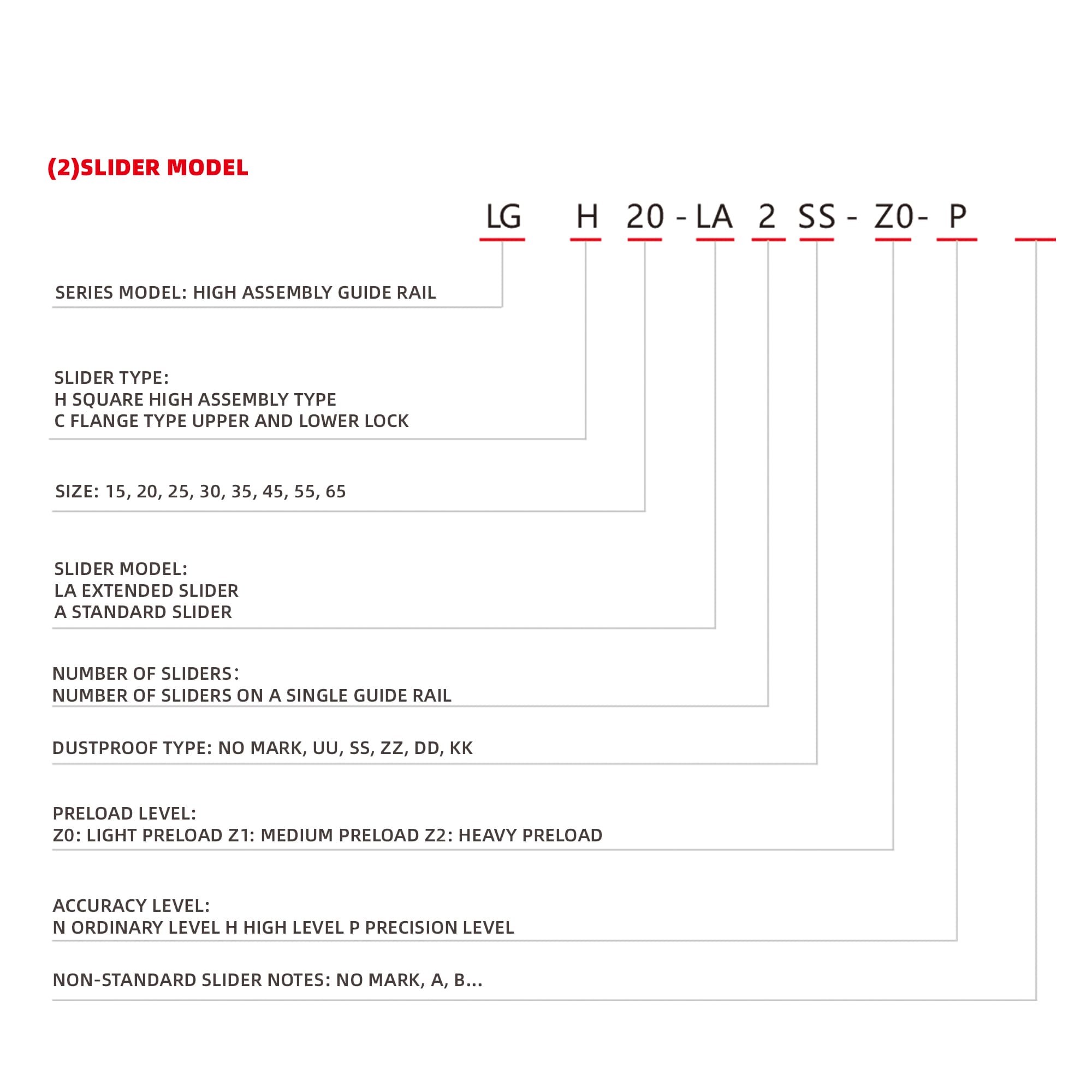

Slider Model

The slider is the part used in conjunction with the guide rail, common specifications and models are as follows.

Preload Level

LG series linear guides provide three standard preloads, and the appropriate preload can be selected according to the application.

1. No preload (Z0, 0~0.02C)

There is almost no gap between the slider and the guide rail, and the friction resistance is small. It is suitable for occasions with fixed load direction, small impact, and low precision requirements. For example, conveying devices, automatic packaging machines, automated industrial machinery, XY axes of general industrial machinery, welding machines, flame breakers, tool exchange devices

2. Medium preload (Z1, 0.05C~0.07C)

Medium preload is suitable for applications with light loads and high precision requirements, and can effectively improve system rigidity and positioning accuracy. For example, the Z axis of general industrial machinery, EDM machines, NC lathes, precision XY platforms, measuring instruments, etc.

3. Heavy preload (Z2, 0.10C~0.12C)

High preload is suitable for use environments with high rigidity requirements, vibration and impact, and can effectively prevent the influence of slider gaps and improve overall stability. Machining center, grinding machine, NC lathe, vertical or horizontal lathe, Z axis of machine tool, etc.

Oil Supply Rate for Linear Guides

| Specifications | Oil Supply Rate (cm³/hr) |

| LG15 | 0.2 |

| LG20 | 0.2 |

| LG25 | 0.3 |

| LG30 | 0.3 |

| LG15 | 0.3 |

| LG45 | 0.4 |

| LG55 | 0.5 |

| LG65 | 0.6 |

Oil Nozzle Position

The LG series features side oil holes on the side of the end cap for installing an oil strip (typically a straight grease nipple) to provide lateral lubrication. While this location is recommended for the non-reference side, it can be placed on the reference side if required.

Please contact us if you require this type of lateral lubrication. For linear guides using automatic grease supply via a pipe connection, the oil pipe connector can be installed based on the type of connecting pipe.

We're Here to Help

Provide you with product consultation and technical support!