Simkawa

LMGQ Linear Guideway

The LMGQ series linear guideways are high-performance linear guides developed based on the design of the LMG series. They offer high rigidity and high load capacity, while also being able to withstand equal loads in all four directions: radial, reverse radial, and lateral. Their self-aligning feature can also absorb mounting surface errors during equipment assembly.

A special resin ball linkage is designed between the steel balls to effectively reduce wear and collision between the balls during operation, while also providing space for lubricant storage, thereby reducing operating noise and extending the slider's service life.

Choose options

LMGQ Linear Guideway Features

1. Based on the LMG linear rail system, this model features a ball linkage, ensuring smooth and quiet operation even at high speeds.

2. The optimized guideway and slider design provides exceptional rigidity and can support heavy loads under harsh conditions.

3. The symmetrical structure provides uniform load capacity in radial, reverse radial, and lateral directions.

4. It automatically compensates for installation errors, improving assembly tolerances and motion accuracy.

5. Integrated end and bottom seals effectively prevent contaminants from entering, extending system life.

simkawa linear guide

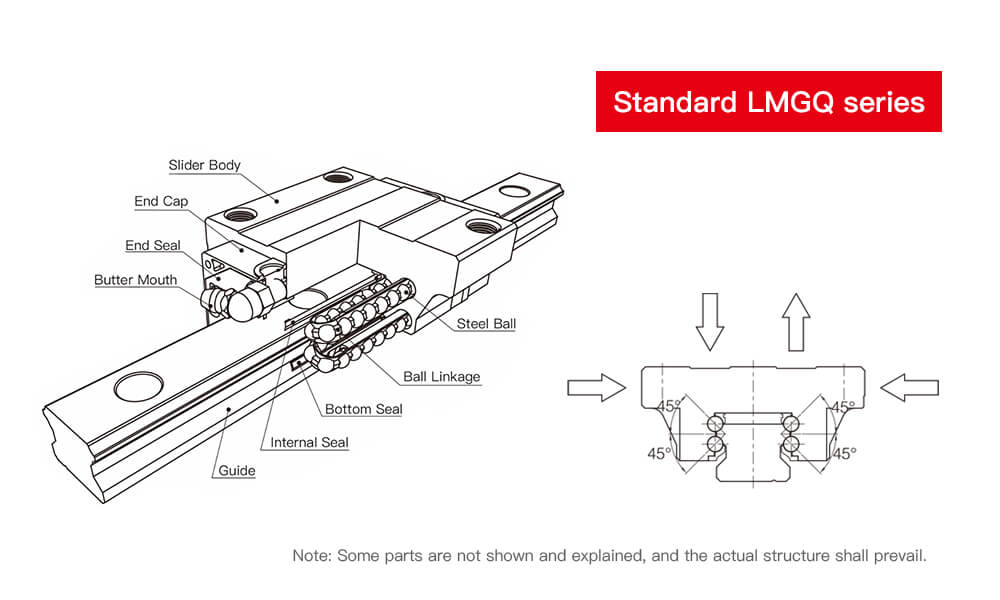

Structures of LMGQ Linear Guideway

Rolling circulation system: slider, slide rail, end cover, steel ball, steel ball retainer

Lubrication system: oil nozzle, oil pipe joint

Dust protection system: oil scraper, bottom dust seal, slide rail bolt cover, metal scraper

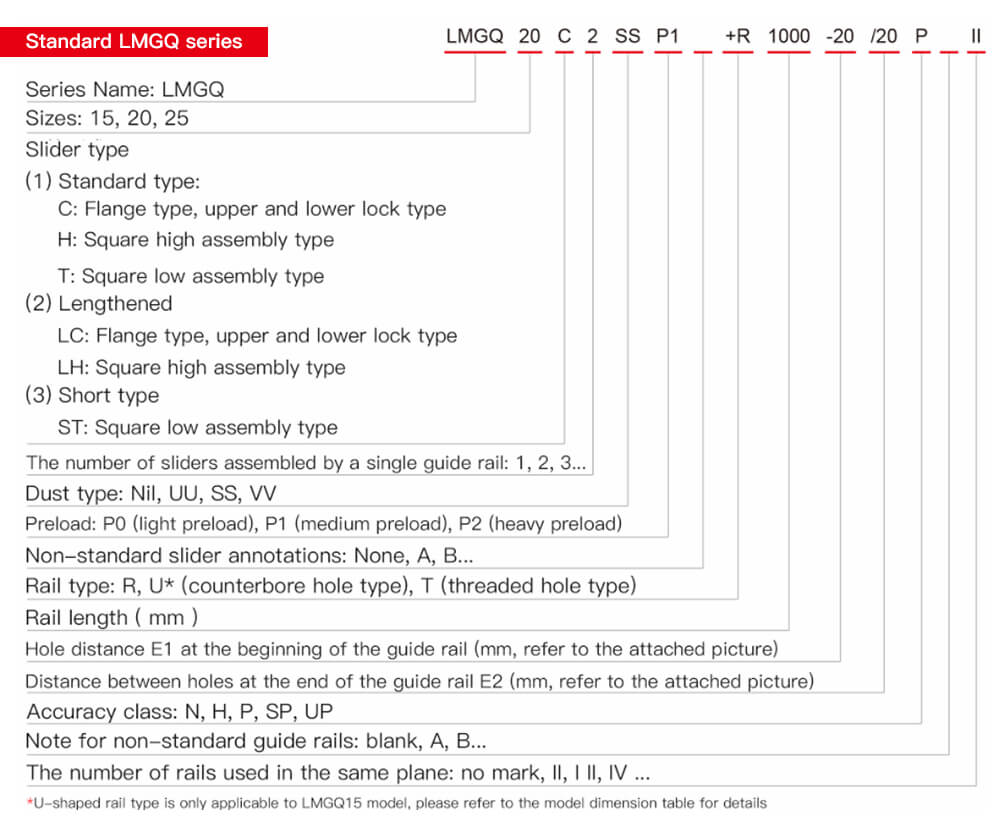

Specifications

Linear Guideway Set

Linear guideway assemblies are usually composed of guide rails and sliders. Common specifications and models are as follows.

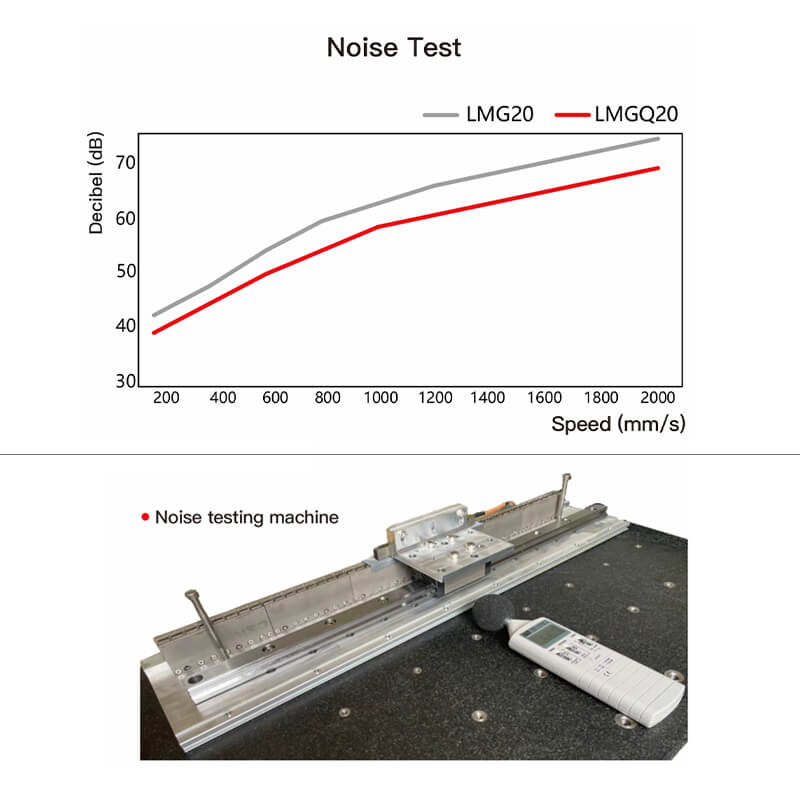

Noise Test

The LMGQ linear rail system utilizes a ball linkage to arrange the balls evenly and evenly, eliminating the sharp sound (high-frequency sound) caused by the balls colliding with each other. Experimental measurements have shown that under different speed conditions, the overall sound of the LMGQ series is effectively reduced by 5-7 decibels compared to the LMG series.

Test Products:

LMG/GQ20H1SSP0+R1200-30/30N

Test Speed:

200mm/s-2000mm/s

Stroke:

1000mm

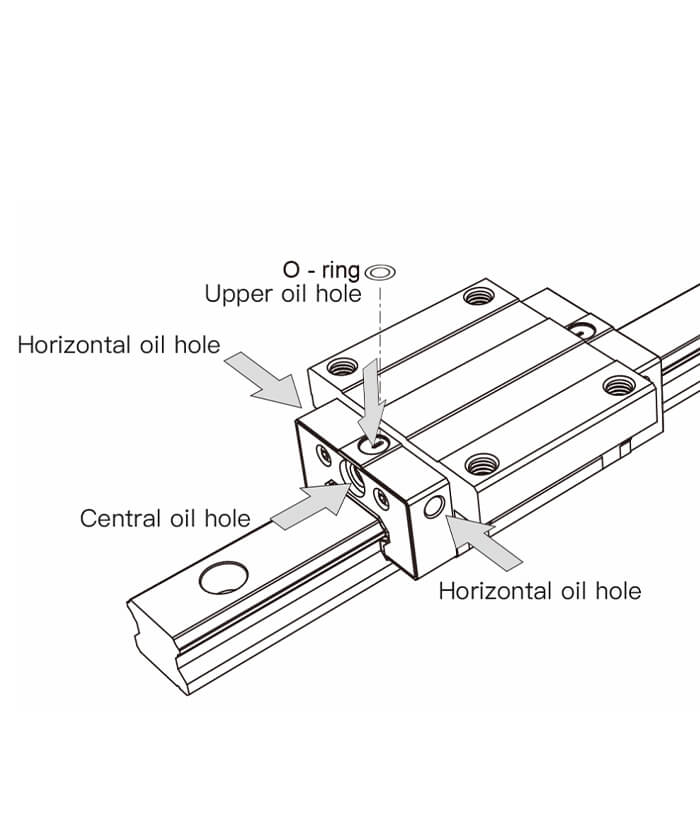

Linear Guideway Lubrication

Proper lubrication is essential when using linear guides. Without adequate lubrication, friction between the rolling elements and the rolling surfaces increases during operation, potentially shortening their lifespan. Linear guides can be lubricated with either grease or oil. Lubrication methods are generally categorized as manual or automatic. The appropriate lubrication method should be selected based on the system's operating speed, operating environment, and other requirements.

Lubrication Method

The frequency of grease application varies depending on operating conditions and environment. Generally, it is recommended to relubricate every 100 km of travel. Simkawa linear guides are pre-filled with lithium soap-based No. 2 grease in the sliders at the factory. Oil lubrication is recommended with a viscosity of 30-150 cSt. When using oil lubrication, the lubricant may have difficulty reaching the rolling grooves in non-horizontal mounting arrangements. Please be sure to specify the mounting method when ordering.

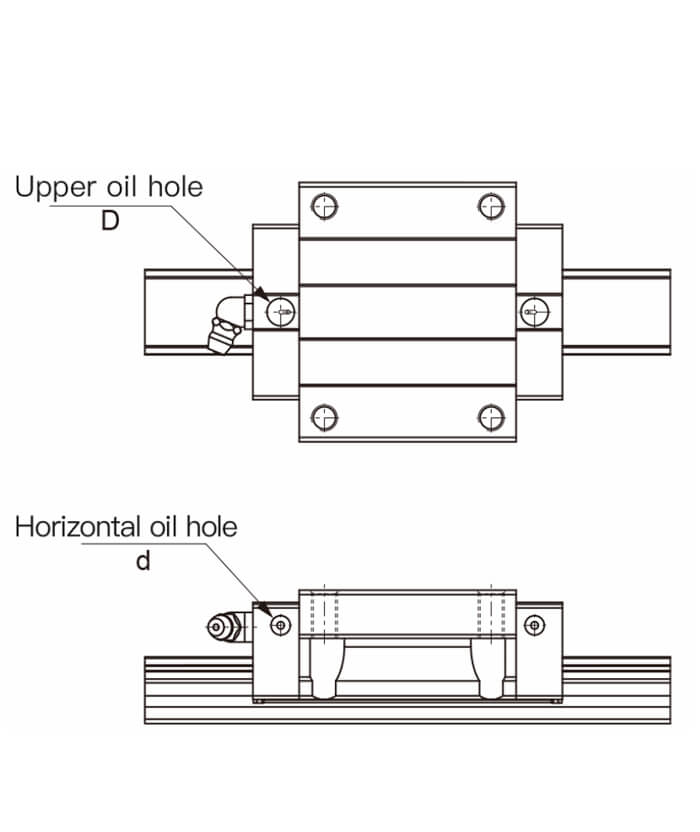

Lubrication Locations

The Simkawa linear rail system provides lubrication locations for the center holes on both ends of the slider and the lateral and upper holes on the end caps, as shown in the diagram and table below. To prevent foreign matter from entering, the lateral and upper holes on the end caps are not through-holes. If lubrication is required, please specify this when ordering.

We're Here to Help

Provide you with product consultation and technical support!