Simkawa

Linear Motor Module LMD Series

The concept of the LMD linear motor module series is to design a direct-drive micromodule with extremely low cross-sectional height, small size and high force by matching high-resolution linear encoders and high-precision roller guides, achieving high precision and extremely low dust generation, which can be used in clean room environments.

Choose options

Linear Motor Module LMD Series Features

- High positioning accuracy

- High acceleration, high response

- Compact structure, space saving

- Excellent stability

- Various configurations available

simkawa linear motor module

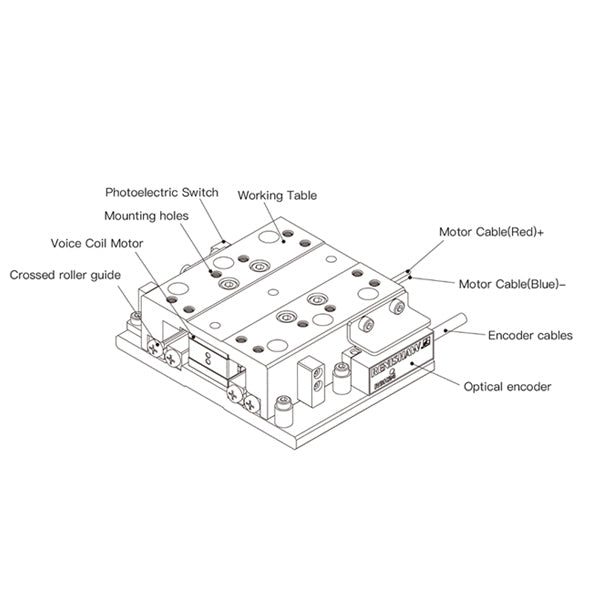

Structures of LMD Linear Motor Modules

LMD series linear motor modules are suitable for high-precision, high-response automation and CNC applications.

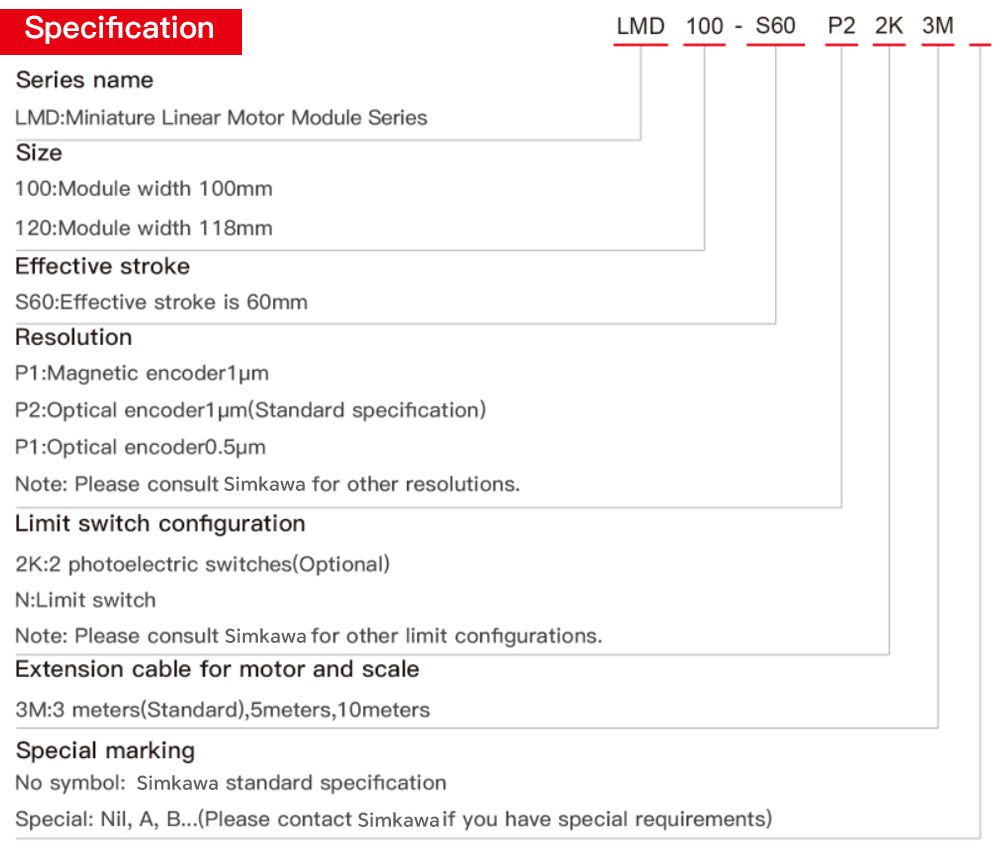

Specifications

LMD Series

The following are common specifications and typical parameter ranges of LMD linear motor modules.

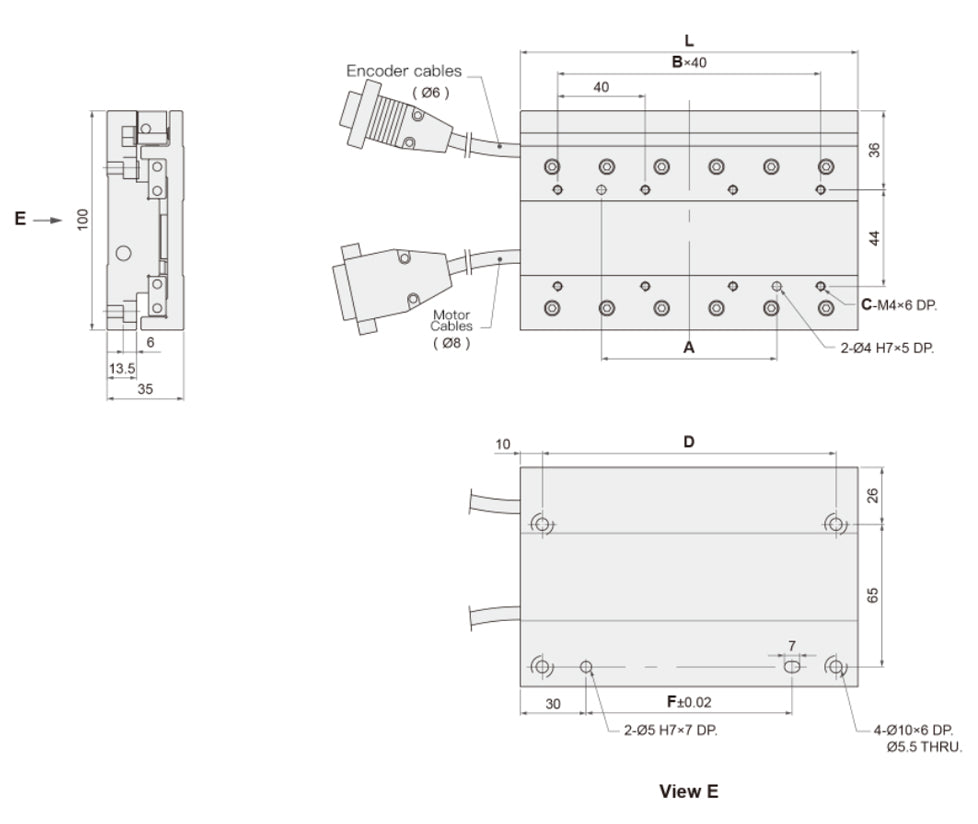

Dimensions

LMD100

Technical Parameters

| Driving method | lron core linear motor |

| Peak force (1s)(N) | 75 |

| Continuous force(@120*C)(N)25 | 25 |

| Effective stroke (mm) | Optional |

| Payfoad (kg) | 3 |

| Max.acceleration (no-load)(G) | 3 |

| Encoder (Magnetic/Optical) | Optical |

| Repeatability(μm) | ±1 |

| Accuracy(μm) | ±3(After the compensation) |

Control and Programming

- The LMD series usually supports a variety of control methods, including servo control, stepper control, etc.

- Micro linear motor module supports commonly used control interfaces such as USB, RS-232, Ethernet, etc., which is convenient for connection with PC or PLC.

Grease Lubrication Steps

- Cleaning: Before adding new grease, clean the lubrication parts of the module to remove old or contaminated grease.

- Add grease: Use a grease gun or appropriate tools to add new grease evenly to the lubrication points, ensuring that the grease covers all moving parts.

- Check for excess: Avoid adding too much grease to avoid damage to seals or affecting motion performance.

We're Here to Help

Provide you with product consultation and technical support!