My Store

LM Guideways

The LM low profile linear guide is designed to reduce the assembly height and shorten the slide length, making it very suitable for high-speed automated industrial machinery and small equipment with space requirements.

Choose options

LM Guide Rail Features

1. Compared with LG rails, LM low profile linear rail has lower combined height and shorter slider length, which is very suitable for high-speed automated industrial machinery and small equipment with space requirements;

2. The four-row steel ball load-bearing design makes it have high rigidity and high load characteristics;

3. The automatic centering function can absorb the assembly error of the mounting surface and obtain high-precision appeal;

4. The slider is equipped with a steel ball retainer to prevent the steel ball from falling off, and it is interchangeable when the accuracy allows.

simkawa linear guide

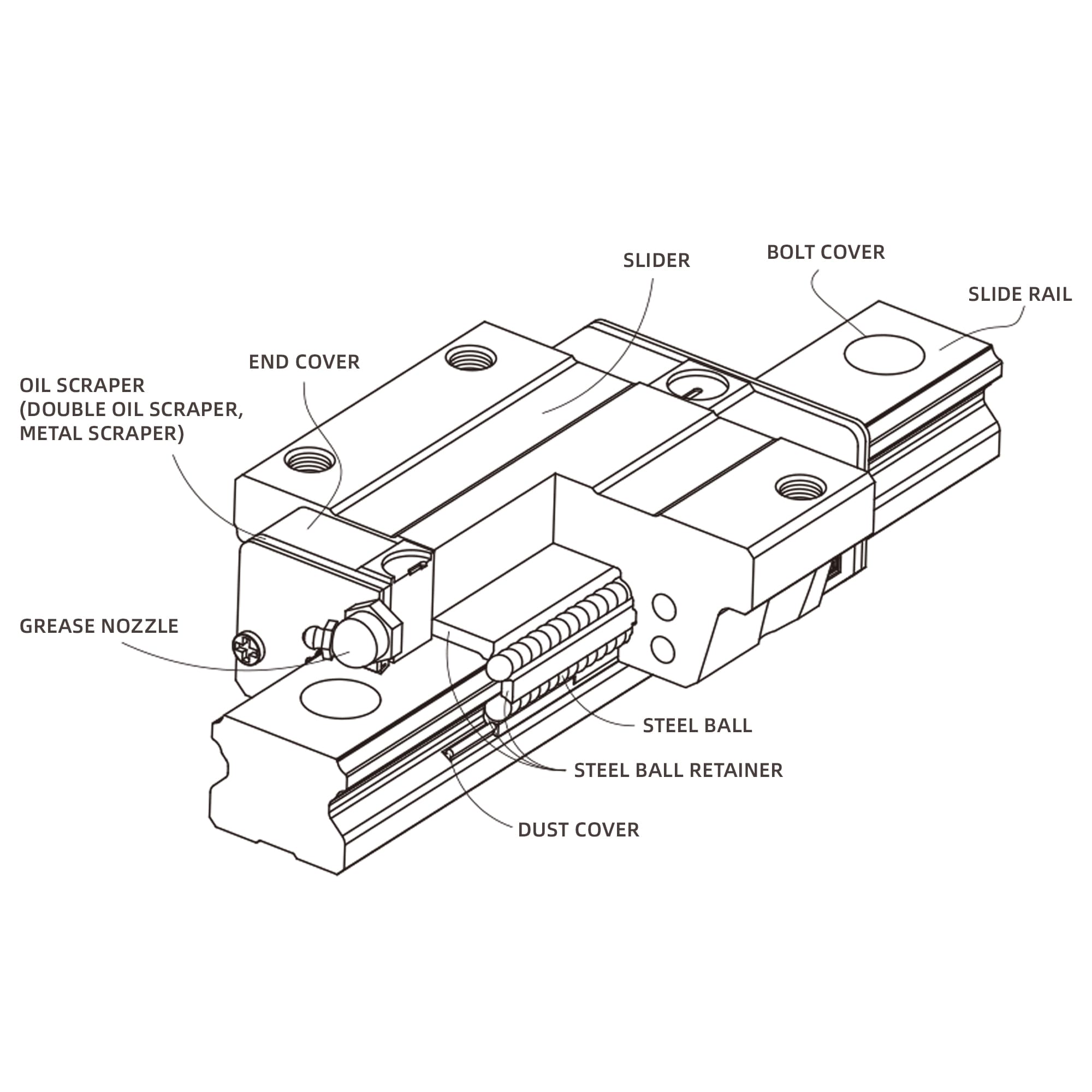

Structures of LM Guides

Rolling circulation system: slider, slide rail, end cover, steel ball, steel ball retainer

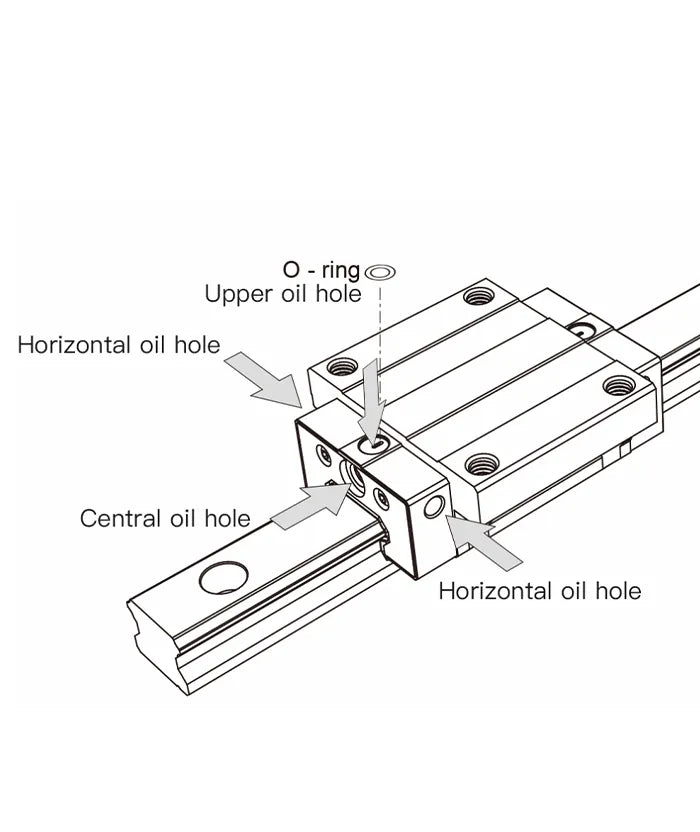

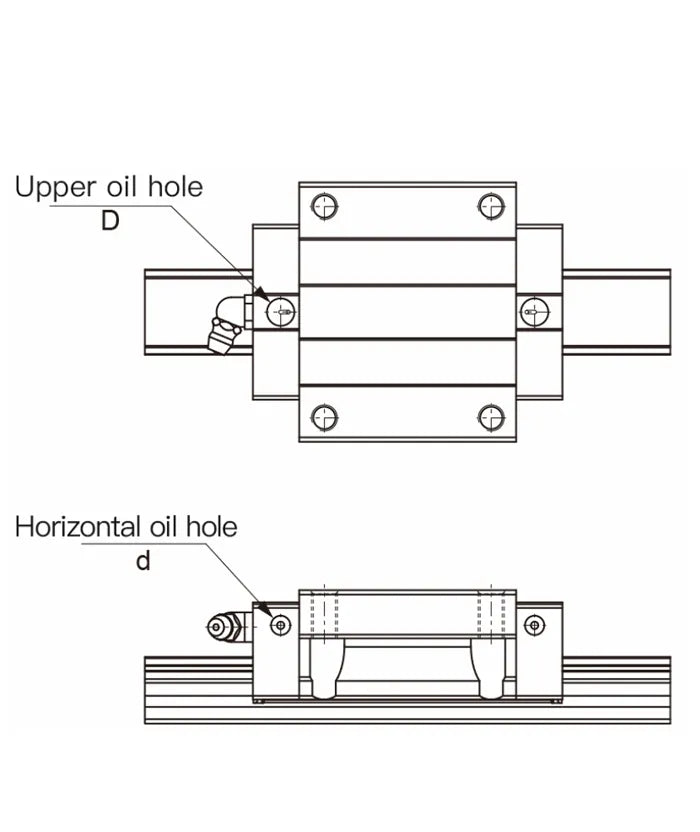

Lubrication system: oil nozzle, oil pipe joint

Dust protection system: oil scraper, bottom dust seal, slide rail bolt cover, metal scraper

Specifications

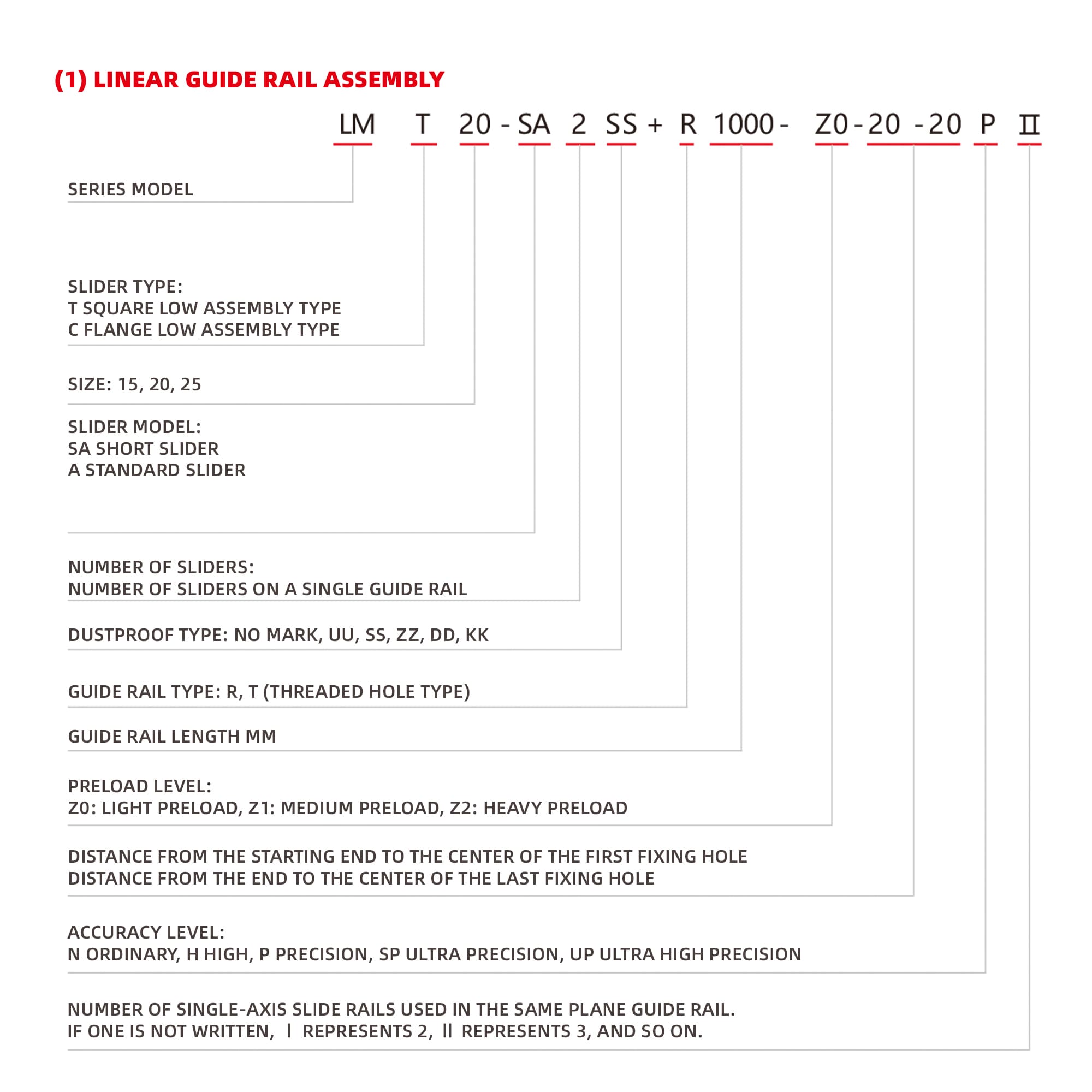

linear Motion Guide Set

Linear guide assemblies are usually composed of guide rails and sliders. Common specifications and models are as follows.

Specifications

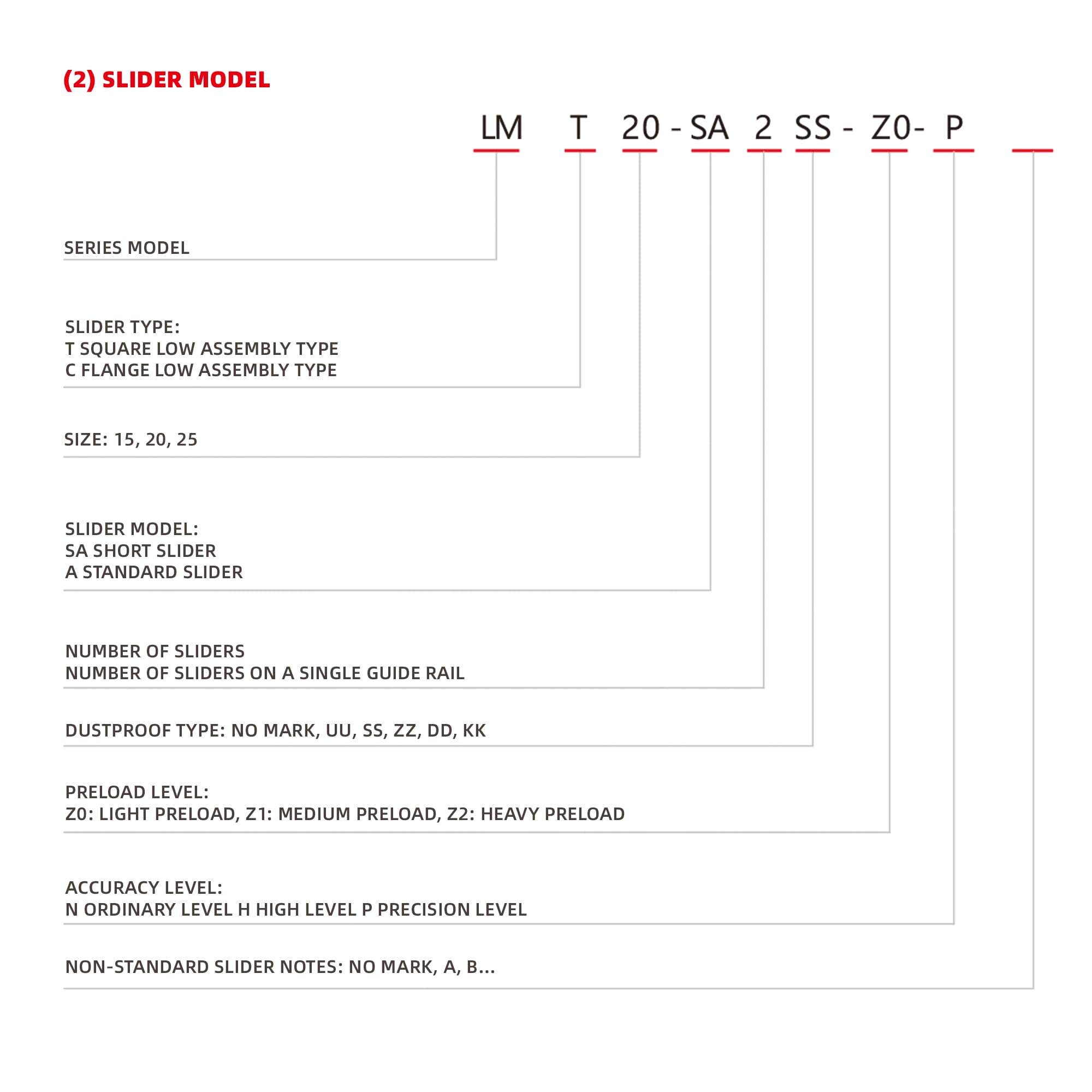

Slider Model

The slider is the part used in conjunction with the guide rail, common specifications and models are as follows.

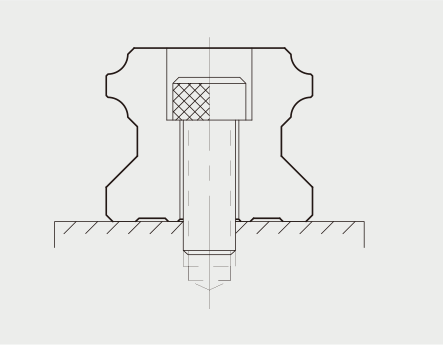

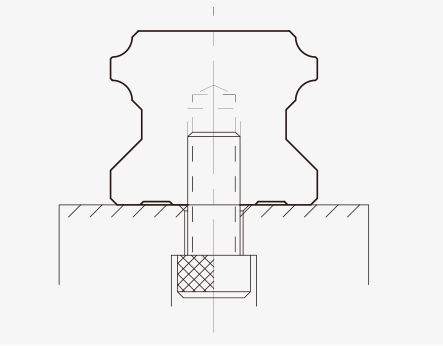

Slide Rail Type

To meet the needs of different installation scenarios, Simkawa has added a bottom-locking structure option based on the traditional top-locking bolt hole slide rail, making installation more flexible and easier to use.

Upper locking bolt hole

Lower locking bolt hole

LM Linear Motion Rails Lubrication Method

LM series also has a reserved oil hole position at the top of the end cover. If the customer wants to supply oil from the top of the end cover, a 0.8mm diameter metal needle must be used to preheat and drill through the oil hole at the specified position, and then install the sealing ring in the recess. Avoid using a drill to drill through the oil hole, and there is a risk of debris contaminating the oil channel. For linear guides that automatically supply grease using a pipe connection, you can choose to install the oil pipe joint according to the type of connecting pipe.

1. Lubricating Grease

Check the grease every 100km of operation, or every 3 to 6 months.

2. Lubricating Oil

It is recommended to use a lubricating oil with a viscosity of about 32~150cSt to lubricate the linear guide. Customers can first tell us that they need to use oil lubrication, and the shipped linear guide will not be sealed with grease.

We're Here to Help

Provide you with product consultation and technical support!