In the field of mechanical processing and automated manufacturing, the guide rail system, as one of the core components of machine tools, processing equipment and motion platforms, directly affects the operating accuracy, service life and production efficiency of the equipment. In recent years, with the development of CNC technology, CNC linear guides have become the standard configuration of more and more high-end equipment, gradually replacing the traditional sliding guide system.

1. What is a Traditional Guide Rail?

Traditional guide rails, also known as sliding guide rails, refer to guide structures that rely on contact sliding between metal surfaces to achieve linear motion. Its forms include rectangular guide rails, dovetail guide rails, V-shaped guide rails, etc., which are commonly used in traditional machine tools such as ordinary milling machines, lathes, and grinders.

- Features

Strong structure and simple processing;

Large contact area and strong impact resistance;

Relatively low cost;

Easy to wear after long-term operation and requires manual scraping.

2. What is a CNC linear guide rail?

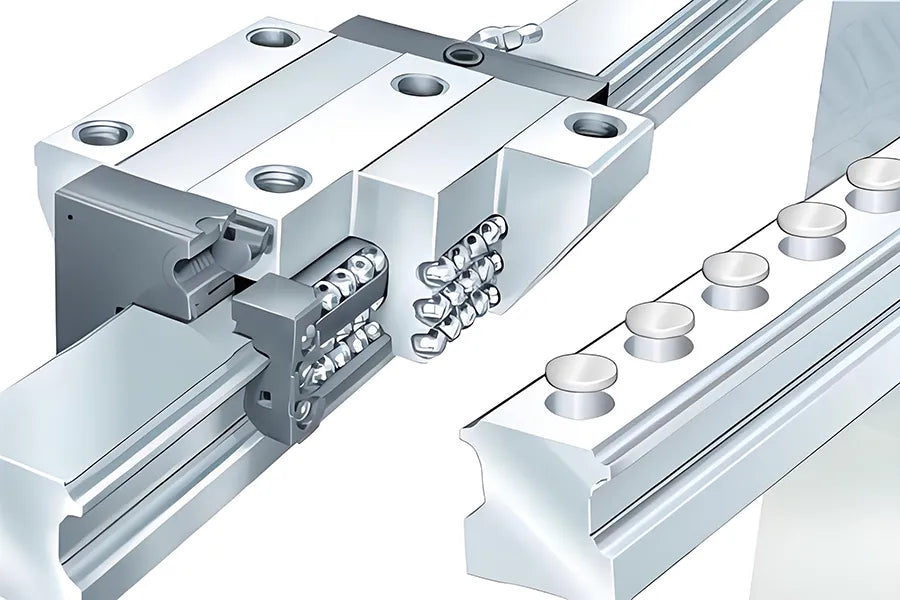

CNC linear guide rails are also called rolling guide rails or linear guide rails. They achieve low-friction and high-precision linear movement by circulating the balls or rollers inside the slider between the tracks. Common brands include HIWIN, THK, PMI, NSK, etc., which are widely used in CNC equipment such as machining centers, engraving machines, laser cutting machines, and automated production lines.

- Features

Low friction coefficient and smooth operation;

High precision and small repeat positioning error;

Strong rigidity and high load-bearing capacity;

Easy installation and long maintenance cycle.

3. Comparison of Structure and Principle

| Comparison Items | Conventional Guides | CNC Linear Guide |

| Movement mode | Sliding friction between surfaces | Balls/rollers rolling in tracks |

| Friction coefficient | High (μ≈0.1~0.2) | Low (μ≈0.003~0.01) |

| Precision retention | Susceptible to wear | Low wear and tear, long life cycle |

| Lubrication requirements | High, regular oil film maintenance is required | Medium, some have self-lubricating structure |

| Installation complexity | High, requires manual scraping | Modular design, easy installation |

4. Comparative Analysis of Performance

4.1 Accuracy and Repeat Positioning Capability

CNC linear guides use rolling elements to reduce friction and achieve high-precision positioning. The repeat positioning accuracy can reach ±0.002mm or even higher. In contrast, traditional guides are prone to precision deviation after long-term use due to uneven wear of the sliding contact surface.

4.2 Movement Stability and Noise Control

Linear guides have lower running noise and less vibration due to the smooth rolling of balls or rollers in the track, which is conducive to high-speed processing. However, traditional guides have high friction and high heat when running at high speed, which is prone to creeping effect.

4.3 Load-Bearing Capacity and Rigidity

Although roller linear guides are very rigid, traditional guides have a large contact area and still have advantages in heavy-load and impact-resistant applications, suitable for large cast iron parts or rough processing equipment.

4.4 Life and Maintenance

CNC linear guides have built-in lubrication channels, dust-proof and corrosion-resistant designs, long maintenance cycles and easier automated management. Traditional guides require manual regular oiling, scraping, and grinding, which requires a lot of maintenance labor.

5. Cost Comparison

Initial investment: Traditional guides have low costs and are suitable for equipment with limited budgets or that does not pursue high-speed processing;

Long-term operation: CNC linear guides have low maintenance costs and high operating accuracy, suitable for modern manufacturing companies that pursue efficiency and precision;

Renovation and upgrading: Many old machine tools can improve performance by modifying linear guides to achieve equipment reuse.

Summary

For equipment manufacturers and users:

- New CNC equipment: It is recommended to give priority to the use of linear guide systems to improve product technical competitiveness;

- Old equipment upgrade: According to the accuracy requirements and budget, partial replacement with rolling guide systems;

- Mixed application scenarios: Large machine tools can consider the combination of "traditional guides + rolling guides" to take into account both rigidity and accuracy.