Compared with traditional sliding guides or ball guides, roller guide rails have significant advantages on heavy-duty CNC machine tools due to their excellent load-bearing capacity and torsional rigidity. This article will explore in depth why roller guides have become the first choice for heavy-duty CNC equipment from multiple dimensions such as structural characteristics, performance, and application value.

1. Structure and Working Principle of Roller Guide Rail

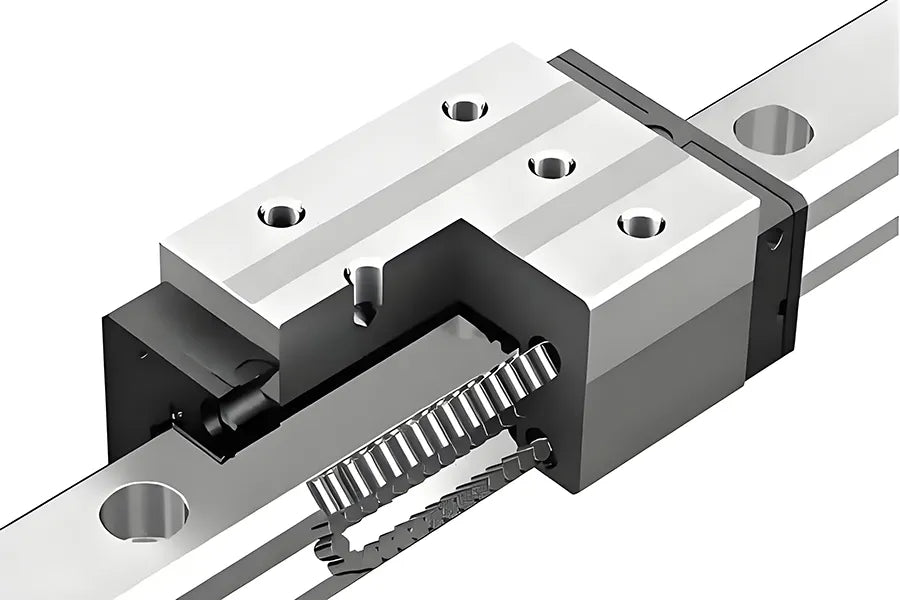

The roller guide rail is a linear motion system with rollers installed inside the slider, which roll between the track and the slider to achieve low-friction, high-precision linear motion. Compared with ball guides, rollers have a larger contact area, so they can withstand greater loads and provide higher rigidity.

Main Structural Components

Guide Rail: After heat treatment and grinding, the surface is smooth and the precision is high;

Roller Block: It is equipped with multiple rollers inside and rolls along the guide rail;

Dustproof system and lubrication mechanism: protect rolling elements and extend service life;

Circulation system: guide rollers to circulate inside the slider.

2. Core Advantages

2.1 Super Strong Load-bearing Capacity

Due to the linear contact between rollers and rails (compared to the point contact of balls), roller guides have a stronger load-bearing capacity per unit area, and the theoretical load-bearing capacity can reach 2 to 3 times that of ball guides. This feature makes it very suitable for heavy workpieces weighing up to several tons or even tens of tons, and is widely used in large milling machines, gantry machining centers, boring and milling compound machine tools, etc.

Example: After using roller guide rails, a heavy-duty five-axis gantry machine tool has achieved continuous 24-hour heavy-duty processing without precision drift.

2.2 High-rigidity Structure

Roller guides have higher rigidity and can effectively resist various impacts, vibrations and load deformations from the spindle direction and the cutting process, and maintain the stability of the machine tool during operation. This is crucial for high-demand scenarios such as heavy cutting, deep hole processing, and large mold processing.

In addition, the load capacity and rigidity distribution of roller guides in multiple directions (X/Y/Z axes) are more balanced, which helps to maintain the dynamic accuracy of the equipment in three-dimensional space.

2.3 High Dynamic Response

Traditionally, roller guide rails are used in low-speed and high-load scenarios, but with the advancement of manufacturing technology, such as the optimization of pre-load structure, the upgrade of lubrication system and the strengthening of guide material treatment, modern roller guides also perform well in high-speed response.

Modern roller guides can support operating speeds of more than 60m/min. Combined with a high-rigidity support system, they can not only withstand heavy loads, but also respond quickly to tool path changes to improve processing efficiency.

2.4 Long Life

Due to the large contact area, uniform force and low friction of roller guides, the wear rate is slow during operation and the service life is longer than that of traditional guides. At the same time, its modular design and preset lubrication channels make maintenance more convenient, the maintenance cycle is long, and the risk of downtime is reduced.

More importantly, many brands of roller guide rail systems have integrated automatic lubrication and intelligent monitoring modules to further reduce the need for manual intervention and improve the overall availability of equipment (OEE).

2.5 Adapt to Various Harsh Environments

Heavy-duty CNC machine tools are often used for cutting difficult-to-process materials such as cast iron, stainless steel, and high-temperature alloys. These processes will generate a large amount of metal chips, high heat, and vibration, which puts higher tolerance requirements on the guide rail system. Roller guide rails have:

- Strong anti-pollution ability;

- Strong compatibility of protective devices;

- Can be matched with steel belt closed structure to extend service life.

- These advantages make it still stable in harsh working conditions such as high temperature, dust, and strong impact.

3. Applicable Scenarios and Typical Applications

Roller guides are widely used in the following heavy equipment fields:

- Large gantry machining center

- Moving column boring and milling machine

- Five-axis linkage machining center

- Large mold machine tools

- Aviation, wind power, rail transportation parts processing

- Especially in the processing of heavy parts such as aviation structural parts, automobile chassis, rail wheels, and ship propellers, roller guides provide solid support and high precision guarantee.

Summary

In summary, roller guide rails have become an irreplaceable and important component in heavy-duty CNC machine tools due to their high load-bearing capacity, high rigidity, long life and excellent performance in adapting to heavy cutting. Although their initial cost is slightly higher than that of ball guides, they have a very high cost-effectiveness in terms of long-term operating stability, maintenance costs and product quality control.