As an important part of modern mechanical transmission, ball screw system has been widely used in precision machine tools, automation equipment and other fields. However, in the long-term use process, the service life of ball screw system has gradually become an important issue that engineers and equipment operators need to pay attention to. This article will explore in depth the factors that affect the service life of ball screw.

1. Design Life

Under normal use, ball screw system will not be able to continue to be used after a period of time due to peeling or insufficient precision due to wear. We call this period the life of ball screw. According to the cause of scrapping, it can be divided into fatigue life and precision life.

1.1 Fatigue Life

Fatigue life refers to the service life of ball screw after long-term use and periodic load, and its material or structure is gradually damaged due to repeated stress, which eventually leads to destruction. Under normal working conditions, ball screw will bear a certain load in each rotation and be subjected to constant pressure and friction. Over time, repeated loads will cause changes in the microstructure of the material, and eventually cracks, peeling or fractures will occur.

1.2 Precision Life

Precision life refers to the service life of the ball screw system during use, due to long-term wear and deformation, resulting in a decrease in positioning accuracy, unstable movement, and inability to meet the needs of precision equipment, and eventually losing its precision performance. Precision is one of the most important indicators of ball screws, because it directly affects the working accuracy of the equipment and the manufacturing quality of the product.

2. Factors Affecting the Service Life of Ball Screws

2.1 Factors Affecting Fatigue Life

- Load size: Larger loads will aggravate the fatigue damage of ball screw materials and shorten their service life.

- Working frequency: Frequent load changes (such as frequent starting and stopping) will increase the risk of fatigue damage and cause early failure of ball screws.

- Lubrication conditions: Improper lubrication will increase friction, causing the ball screw to bear more mechanical stress under high load, thereby accelerating fatigue damage.

- Material quality: The manufacturing material and heat treatment process of the ball screw system have an important influence on its fatigue life. High-quality materials and fine heat treatment can improve its load-bearing capacity and extend its service life.

2.2 Factors Affecting Precision Life:

- Wear and friction: The surface of the nut and screw of the ball screw system will wear as the use time increases. Surface wear increases friction, which reduces the stability of movement and leads to a decrease in accuracy.

- Load variation: When the load exceeds the design load capacity of the ball screw, it will cause local overload, increase the wear between the nut and the screw, and thus affect its accuracy.

- Insufficient lubrication: Insufficient lubrication or the use of improper lubricants will increase friction, increase wear, and directly affect the maintenance of accuracy.

- Temperature and environmental factors: Excessive temperature or harsh working environment (such as moisture, dust or corrosive gases) will accelerate the aging and wear of materials, leading to a decline in accuracy.

3. How to Check the Condition of the Ball Screw System?

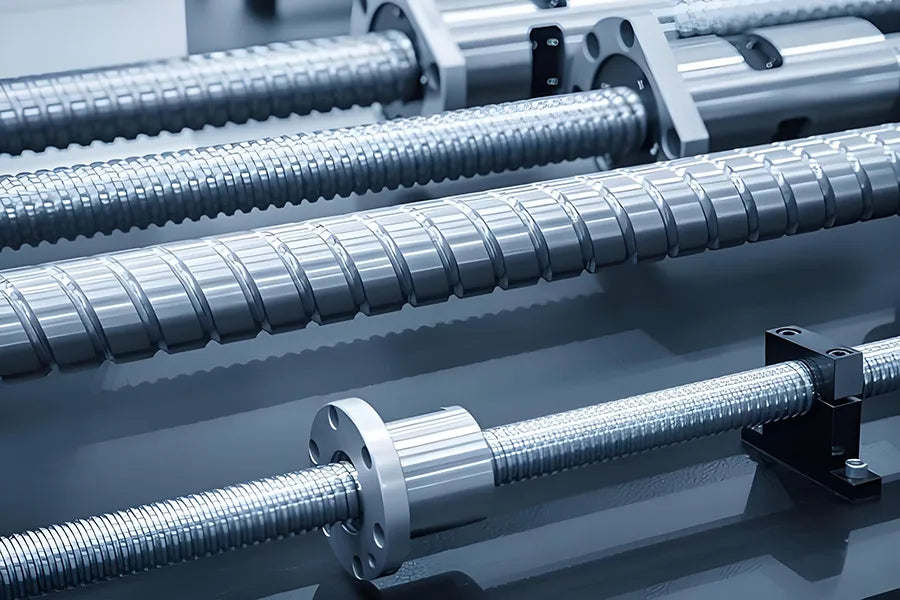

3.1 Check Surface Damage

Cracks: Check the surface of the ball screw thread for cracks or other obvious damage. Cracks may be caused by fatigue or overload.

Corrosion: Check the surface of the ball screw for signs of rust or corrosion, especially for equipment used in humid or harsh environments. Corrosion can cause the surface hardness to decrease, which in turn accelerates wear.

Wear: Observe the contact surface of the ball screw system, especially the threaded part, for uneven wear or surface peeling.

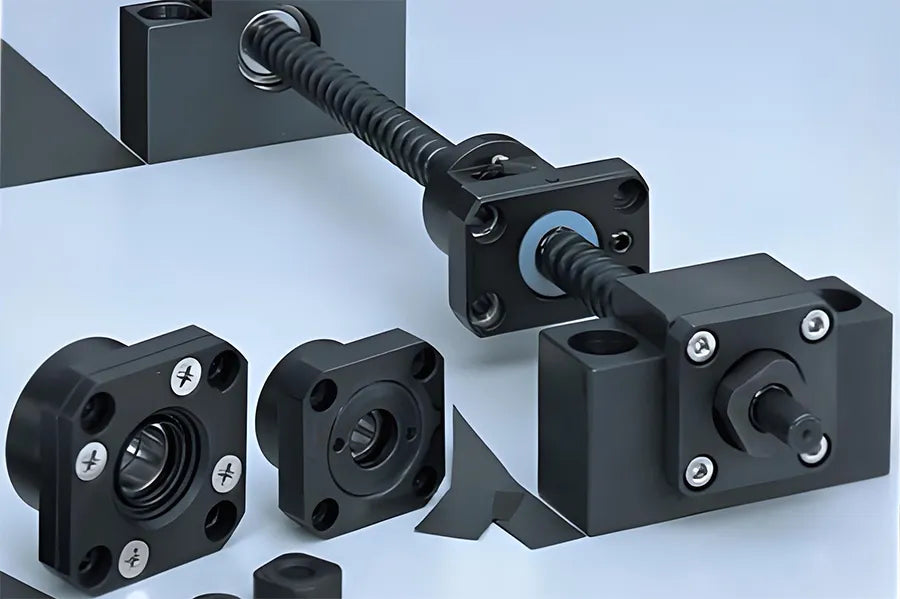

3.2 Check the Ball Screw Nut

Check the part where the nut contacts the screw for obvious pits or signs of wear. This may indicate that the ball inside the nut is damaged or worn.

3.3 Check Lubrication

Check the condition of the grease or oil to ensure that it is evenly distributed and free of contamination. If lubrication is insufficient, the ball screw will be much less efficient and prone to excessive wear.

3.4 Manual Rotation Inspection

Gently rotate the ball screw system by hand to feel for resistance or uneven movement. If the ball screw gets stuck or makes unusual noises when rotating, it may indicate that the nut or ball is damaged.

Check for uneven rotation resistance. Excessive or uneven resistance may be due to wear or deformation of the ball screw threads.

3.5 Clearance of Bearings or Nuts

Check the clearance between the nut and the screw of the ball screw system. Excessive clearance may be due to wear caused by long-term use or looseness of the ball screw.

If you feel looseness between the bearing and nut of the screw, you may need to readjust or replace the parts.

Summary

As a core component in precision transmission systems, the service life of ball screw systems directly affects the overall operating performance of the equipment. Through reasonable load management, a good working environment, effective lubrication and regular maintenance, the service life of ball screws can be significantly extended, equipment downtime can be reduced, and production efficiency can be improved.