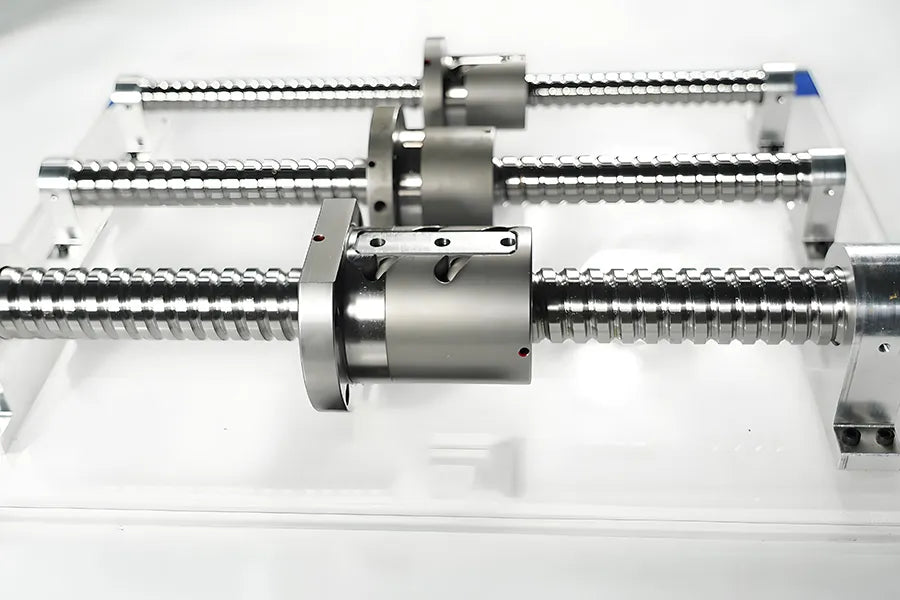

Ball screw transmissions are efficient transmission elements that convert rotational motion into linear motion. They are widely used in CNC machine tools, precision instruments and automation equipment. The selection process involves many requirements such as accuracy, life, speed, rigidity, environmental adaptability, etc., which must be systematically considered.

1. Clarify the Use Conditions

This is the basic stage of the entire selection, and the following information needs to be fully collected and evaluated:

- Load (static/dynamic)

- Speed and acceleration

- Maximum stroke

- Positioning accuracy and repeatability

- Expected life

- Use environment (such as high temperature, vibration, dust, corrosive gas, liquid)

- Lubrication conditions (whether there is a lubrication oil circuit, dust prevention requirements)

These conditions will directly determine the type, accuracy level, lead and protection requirements of the selected ball screw.

2. Lead Accuracy Judgment

Based on the above-mentioned usage conditions, select the lead accuracy of the ball screw transmission:

If there are strict requirements for positioning accuracy, backlash, etc. (such as CNC machining centers, semiconductor equipment), it is recommended to choose a high-precision ball screw;

If it is general automation equipment, handling equipment, etc., you can choose an ordinary industrial ball screw.

3. Screw Shaft Design

The goal of this stage is to preliminarily determine the ball screw transmission specifications, including:

- Shaft diameter (based on load and rigidity requirements)

- Stroke (based on mechanical structure size and range of motion)

- Lead (affects speed and thrust)

- Total length of screw (including installation and support dimensions)

If a preload design is used, the effect of screw length on system rigidity must also be considered.

4. Drive Torque Calculation

Based on load, speed and friction coefficient, calculate the torque required to drive the motor:

T= F⋅p/2π⋅η

Where:

T: Torque (Nm)

F: Axial load (N)

p: Lead (mm)

η: Transmission efficiency (generally 0.85~0.95)

The calculation results will affect the selection of motors and control systems.

5. Confirmation of End Processing

Determine the end processing dimensions according to the connection method (such as coupling, support bearing, flange nut, etc.), including:

- Shaft end diameter

- Location shoulder size

- Keyway/flat key/thread and other interface forms

- End processing is the key to ensure that the ball screw can be connected to the motor and support seat.

6. Nut Design

The nut part should be used in conjunction with the ball screw transmission. When selecting, you need to confirm:

- Nut model (such as cylindrical type, flange type, double nut type)

- Return ball structure (internal circulation/external circulation)

- Pretightening method (improve rigidity and positioning accuracy)

- Whether dustproof and protection are required

7. Rigidity Detection and Comprehensive System Evaluation

The nut, screw, support structure, motor transmission, etc. are combined into a system to conduct a comprehensive evaluation of the system rigidity. Insufficient rigidity will lead to:

- Reduced accuracy

- Resonance or overshoot

- Poor acceleration response

Therefore, special attention should be paid to the influence of structural support and fixing methods (such as fixed-fixed, fixed-free and other support structures) on the critical speed and rigidity of the system.

8. Positioning Accuracy Verification

Based on known factors such as lead error, ball clearance, thermal expansion, etc., evaluate whether the positioning accuracy of the entire system meets the requirements.

If not, it is necessary to:

- Improve the accuracy level of the ball screw transmission

- Increase preload rigidity

- Optimize lubrication/installation

9. Life Design and Confirmation

The following basic formula can be used to calculate the service life:

L₁₀ =( C/F ) ³×10⁶ (unit: number of revolutions)

Where:

L₁₀: rated life (number of revolutions)

C: basic rated dynamic load (N)

F: actual axial load (N)

The service life or operating cycle is obtained by converting the stroke to confirm whether the life meets the design requirements.

10. Precautions (Lubrication and protection)

- All ball screw transmissions should be well lubricated to reduce wear;

- Select appropriate lubricating grease or oil mist lubrication;

- In environments such as dust, debris, and corrosive gases, it is recommended to use nuts with dustproof seals;

- If there is a high temperature environment, high temperature resistant materials and lubricants need to be selected.

Summary

As a high-performance transmission element, the selection of ball screw transmissions needs to be considered comprehensively from multiple dimensions: including load, speed, stroke, accuracy, life, and structural matching. Reasonable selection can not only improve the performance and reliability of the mechanical system, but also greatly reduce maintenance costs and operating risks.