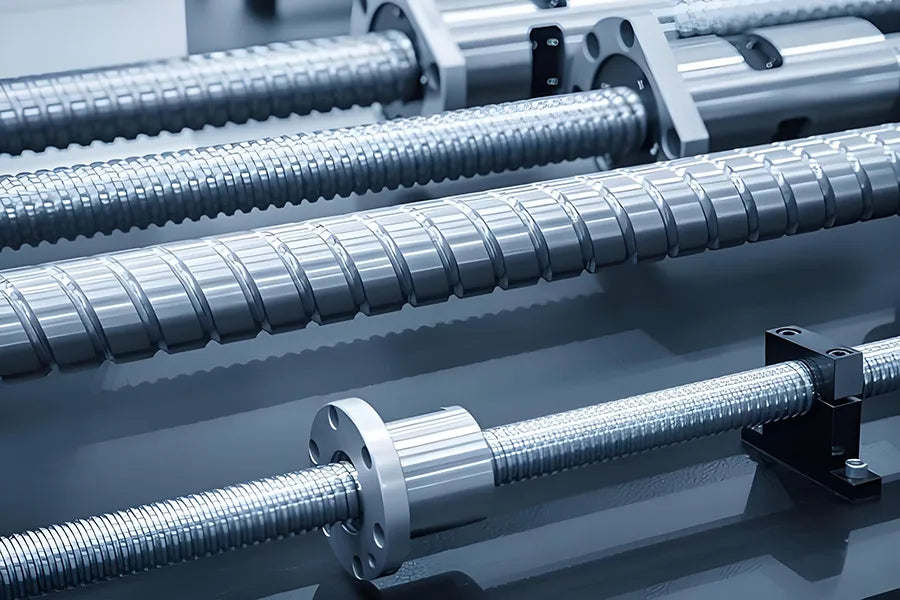

In modern mechanical transmission systems, ball screws are efficient and precise transmission elements that convert rotary motion into linear motion or linear motion into rotary motion. The performance of ball screws is affected by many factors, among which the accuracy grade is the key parameter that determines its motion accuracy, repeatability, stability and life. This article will explore the accuracy grade, application and actual impact of ball screw performance.

1. What is the Accuracy Grade of Ball Screws?

The accuracy grade is an important indicator for measuring the manufacturing and transmission accuracy of ball screws, mainly describing the deviation range of its pitch error, cumulative error, axial clearance, coaxiality, rotation error, etc. The higher the accuracy grade, the smaller the position deviation of the screw during operation, the more stable the movement and the better the repeatability.

2. What Ball Screw Performance Does the Accuracy Grade Mainly Affect?

2.1 Positioning Accuracy

The higher the accuracy grade, the smaller the pitch error of the ball screw, which means that the linear distance deviation of the screw is smaller for each rotation of the motor. This is crucial for the final processing size control of CNC machine tools.

For example: the pitch error of a C1-grade lead screw can be controlled within ±5μm/300mm, while that of a C7-grade lead screw may reach ±50μm/300mm, a difference of 10 times.

2.2 Repeatable Positioning Accuracy

When a high-precision lead screw repeatedly moves to a certain point, its position error is extremely small, ensuring repeated processing accuracy. For example, equipment such as IC packaging and laser cutting that require repeated positioning have extremely high performance requirements.

2.3 Movement Stability

High-grade lead screws have significant advantages in nut-screw clearance control and trajectory smoothness, and can achieve smooth movement without jitter or jamming, effectively reducing vibration and noise during operation.

2.4 Backlash Control Capability

Backlash refers to the axial clearance of the lead screw during reversing. High-precision lead screws mostly use a double nut preload structure, which can compress the axial clearance to zero, ensuring that there is no lag in reversing, which is extremely critical to dynamic response.

2.5 Service Life and Reliability

Screws with high precision levels are manufactured more rigorously in terms of raceway finish, hardening treatment, consistency, etc., so they have longer service life and better fatigue resistance, and are suitable for high load and long-term operation conditions.

3. How to Choose the Accuracy Level Correctly?

To choose the appropriate screw accuracy level, it is necessary to combine the following factors for comprehensive evaluation:

Equipment type and functional positioning: precision processing equipment vs. coarse positioning mechanism

Cost budget: High precision is more expensive, is it worth investing?

Operating environment: Will high temperature, dust, and vibration affect the accuracy effect?

Drive system matching: Can the servo system give full play to the performance of high-precision screws?

At the same time, it should be noted that high-precision screws are not equal to high-precision systems. The guide rails, assemblies, temperature control systems, feedback devices, etc. of the whole machine must also be matched to truly achieve high-precision transmission.

Summary

As the core component of precision mechanical transmission, the accuracy level of ball screws directly affects the motion performance, processing capacity and service life of the equipment. Understanding the characteristics and applicable scenarios of different accuracy levels can help engineers select and configure more scientifically and avoid the problems of "performance waste" or "insufficient accuracy".