As a high-precision and high-efficiency transmission element, ball screws are widely used in CNC machine tools, automation equipment, medical instruments and other occasions that require extremely high motion accuracy. However, under long-term operation or improper maintenance, its accuracy may gradually decrease, which may seriously affect the overall performance and processing quality of the equipment.

This article will deeply analyze the common reasons for the reduction of ball screw accuracy to help engineers and users better understand, prevent and maintain the service life and accuracy performance of ball screws.

1. Precision Reduction Caused by Wear

1.1 Raceway Wear

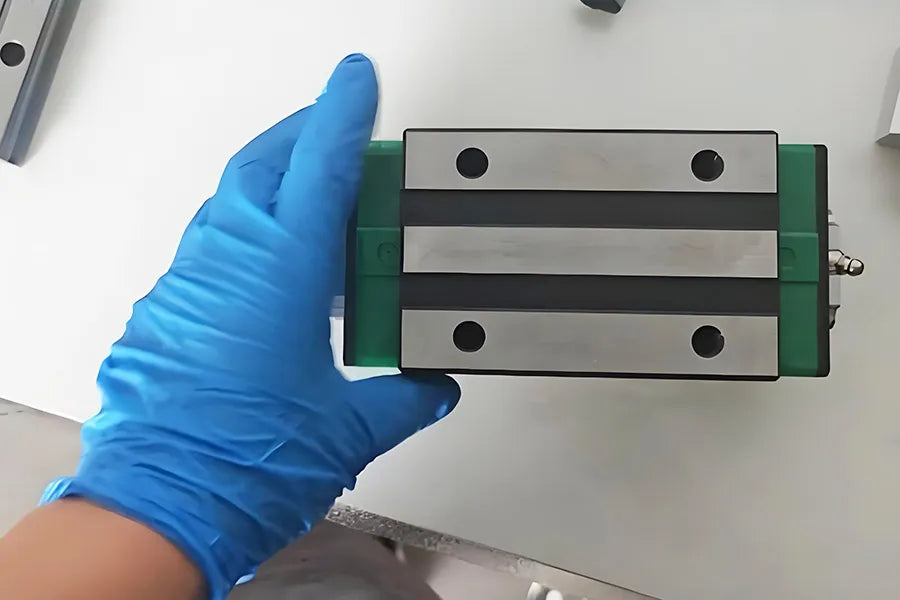

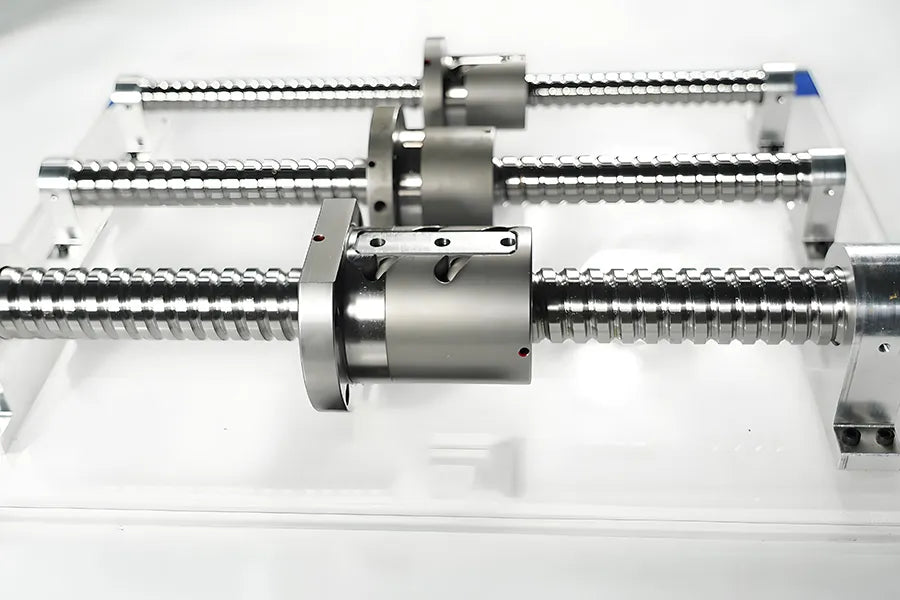

The core working principle of the ball screw is to achieve low-friction and high-efficiency transmission through the rolling of the ball between the nut and the screw. Under long-term high-speed and high-load operation, microscopic metal fatigue and wear will occur between the ball and the raceway.

Manifestations:

Increased axial clearance

Reduced repeat positioning accuracy

Increased backlash error

1.2 Ball Wear

As a rolling medium, the ball will also wear due to insufficient lubrication, excessive load or contaminants, resulting in uneven rolling or out-of-round.

Impact:

Less stability of screw drive

Stick-slip phenomenon

2. Poor lubrication or lubrication failure

Lubrication is essential for ball screws. Lack of lubrication will cause direct metal contact, increased wear, heat accumulation, and thermal deformation, affecting accuracy.

- Common problems include

Use of inappropriate lubricating oil or grease

Lubricating oil drying up or deterioration (such as oxidation by high temperature)

Improper lubrication system design (such as insufficient oil supply or uneven distribution)

- Recommendations

Use lubricants recommended by the manufacturer

Check the lubrication status regularly and replenish or replace when necessary

It is recommended to install an automatic lubrication system

3. Intrusion of pollutants

Once external dust, cutting fluid, coolant, water vapor and other pollutants invade the interior of the screw, they will accelerate the wear of the raceway and the ball, corrode the metal surface, and may block the ball circulation channel.

- Consequences of Contamination

Increased rolling resistance

Unsteady movement, vibration

Sudden change in accuracy (especially at certain stroke positions)

- Preventive Measures

Install dust cover (such as corrugated protective cover or metal cover)

Keep the working environment clean

Strictly prevent cutting fluid from penetrating

4. Loss of Accuracy Due to Improper Installation

If the ball screw is not centered during installation, the bearing is not preloaded, or the support structure is not rigid enough, the accuracy will be affected.

- Common Errors Include

Misalignment between the screw axis and the motor shaft

Excessive installation force, resulting in bending deformation

The nut seat or support seat is not firmly fixed

The installation is not repeatedly tested for stroke and positioning accuracy verification

- Results

Accuracy drift occurs in the initial use

Intensified mechanical vibration

Accelerated local fatigue damage of the raceway or ball

5. Overload Use

When the ball screw is operated beyond its rated axial load (especially dynamic load), it will cause microscopic plastic deformation of the raceway, damage its rolling surface structure, and even spalling.

- The manifestations of overload include

Abnormal increase in rolling sound

Increased operating temperature

Rapid decrease in accuracy, or even sudden failure

- Countermeasures

Accurately calculate the load and motion parameters, and select the ball screw of appropriate specifications

Add protection mechanisms (such as buffer devices) to systems with large operating load fluctuations

6. Thermal deformation effects

After long-term operation, the ball screw will undergo thermal expansion due to friction heat or external heat sources, resulting in changes in the axial length of the screw, affecting the positioning accuracy. This is especially obvious in high-speed movement or long-stroke screws.

- Performance

Regular deviations in processing dimensions

Poor positioning repeatability

Significant increase in temperature in the center area of the screw

- Countermeasures

Install a screw cooling system

Use a hollow screw for forced cooling

Optimize the screw material (such as using low-expansion alloys)

7. Expiration of Service Life or Fatigue Failure

Even under ideal operating conditions, ball screws have a limited service life. As fatigue accumulates in the raceway and balls, microcracks and pits gradually appear in the material, which ultimately makes it difficult to maintain accuracy.

- Features

Accuracy indicators (such as position error, repeatability) continue to decline

Rolling feel becomes rough

Metal peeling or pitting occurs on the surface

- Suggestions

Replace the lead screw regularly according to the number of strokes or usage time

Use sensors with early warning functions to monitor the lead screw status

Choose high-quality brands with long-life design

Conclusion

The accuracy of the ball screw is one of the key parameters affecting the performance of the equipment. Any slight loss of accuracy may cause processing errors, unstable operation, shortened equipment life and other problems. Through scientific maintenance, reasonable use and regular inspection, the life of the lead screw can be effectively extended to ensure long-term and efficient operation of the equipment.