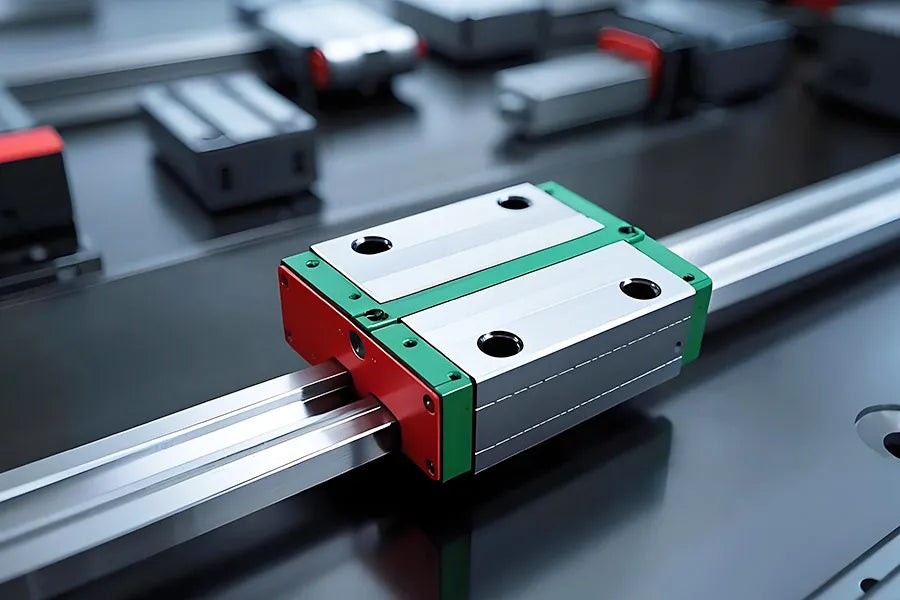

The operating accuracy, speed, and smoothness of a linear guide rail system directly impact the performance of the entire machine. Lubrication is one of the most critical yet often overlooked maintenance elements to ensure long-term stability, smooth operation, and protection from abnormal wear. This article systematically explains linear guide lubrication to help extend equipment life and avoid downtime.

1. Why are Linear Guides Essential for Lubrication?

If linear guides are not properly lubricated, friction in the rolling elements will increase, which, over time, can shorten their lifespan.

Lubricants provide the following functions:

Reducing friction in the rolling elements, preventing burns, and reducing wear.

Forming an oil film between rolling surfaces extends rolling fatigue life and prevents rust.

2. Common Lubrication Methods for Guide Systems

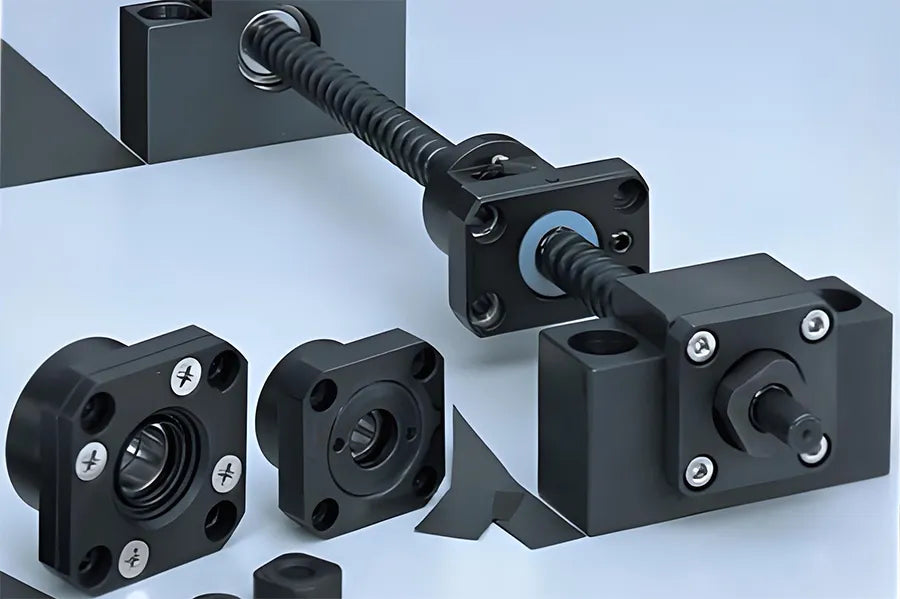

Grease: Grease has high viscosity, is nonvolatile, and has excellent sealing properties. It is suitable for most common guides and offers long maintenance intervals. Each linear guide rail system is lubricated with a ball groove track. Although grease is relatively easy to lose, to prevent lubrication depletion, it is recommended that customers re-lubricate after a distance of 100 km. Grease can be applied to the slide using a grease gun using the attached nipple. Grease is suitable for speeds up to 60 m/min and where cooling is not required.

Lubricant: It has good fluidity, fast cooling, and is suitable for high-frequency systems. It is recommended to use a lubricant with a viscosity of approximately 32-150 cSt for linear guide rails.

3. Setting and Checking the Lubrication Cycle

Lubrication frequency depends on the linear guide rail system type, operating environment, and workload. Common reference intervals are as follows:

Low speed, light load, clean environment: Re-lubricate every 6-12 months;

Medium speed, normal temperature: Re-lubricate every 3-6 months;

High speed, high load, or dusty environment: Check lubrication status monthly or weekly.

It is recommended to observe the color of the drained oil during each lubrication. If the oil is black, contains impurities, or metal particles, replace it promptly and inspect the slide for wear.

4. Proper Lubrication Procedure (Grease as an Example)

Stop the machine and confirm the position of the slider;

Use a dedicated grease gun or syringe to connect the lubrication hole on the slider;

Inject grease evenly and slowly until new grease flows out of the drain port;

Slide the slider repeatedly several times to evenly distribute the grease;

Remove excess grease to prevent dust accumulation and contamination.

Summary

Lubrication is an essential and fundamental safeguard for ensuring the continuous and stable operation of linear guide rail systems under high-precision, high-frequency, and high-load conditions. Proper lubrication not only significantly extends guide life and reduces failure rates, but also improves equipment efficiency and reduces maintenance costs.