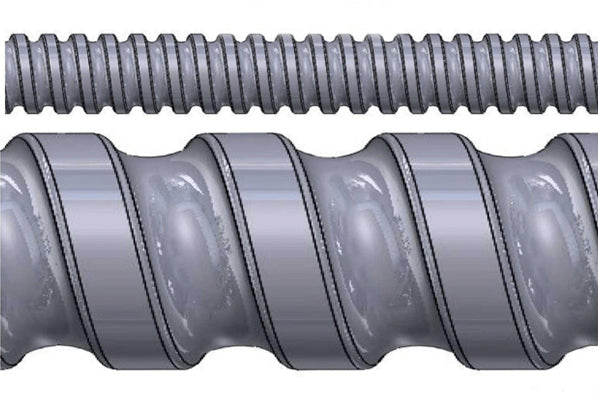

As a core component in precision transmission systems, the accuracy of a servo ball screw directly impacts the positioning accuracy and operational stability of the entire device. To ensure high precision in a ball screw system, control must be exercised across multiple stages, including design, manufacturing, installation, and maintenance.

1. How is Servo Ball Screw Accuracy Characterized?

The accuracy of a ball screw is characterized by lead error. What is lead error? Lead error refers to the deviation between the theoretical and actual distance traveled by the nut as it rotates with the screw shaft. This deviation depends on the manufacturing precision of the ball groove, component tightness, and varies with different screw lead pitches.

2. How Can Ball Screw Lead Accuracy be Improved?

Methods for improving ball screw lead accuracy include increasing preload, lubrication, and improving installation accuracy.

2.1 Increasing Preload

Preloading applies axial force to the balls and grooves of the screw shaft and nut to ensure a tight fit.

This process enhances rigidity and eliminates backlash. Backlash is the loss of motion caused by the gap between the ball and the nut or screw track, which affects accuracy and repeatability and is critical for precise positioning applications. The choice of preload determines whether the servo ball screw uses a single ball nut or a double ball nut. Common preloads in ball screw assemblies include:

- Washer Preload

A washers is placed between the two ball nuts to achieve preload. The washers apply force to the adjacent sides of the two nuts, which is then transmitted to the nuts and grooves. This method is usually used to set a larger preload.

- Spring Preload

A spring is placed between the two ball nuts to transmit preload. The spring applies tension to the adjacent sides of the ball nuts.

- Offset Lead Preload

During machining, the groove is offset on the lead line at the center of the loop. This method is more compact than the double nut mechanism because it eliminates the need for washers or springs, but it will make the lead longer and reduce the load capacity.

- Oversized Ball Preload

Oversized ball preload refers to using larger ball bearings to generate preload, increasing the contact area between the ball and the groove, and making the structure more compact. However, this method produces minimal preload and is suitable for applications where precision is less critical.

Optimizing the ball screw's preload and maintaining it during operation is crucial. However, greater preload is not always better. Excessive preload requires increased torque and can also lead to increased heat generation.

2.2. Increased Lubrication

Lubrication is crucial for ball screws, helping prevent premature wear and improving performance by reducing friction and heat. Oil and grease both have a cooling effect. Overheating can cause thermal expansion of components, which can affect ball screw accuracy.

Poor lubrication can lead to wear—microscopic tearing of metal surfaces due to constant friction. This problem is common in nuts, bolts, threaded fasteners, and ball screw threads, and can negatively impact the function of the ball screw.

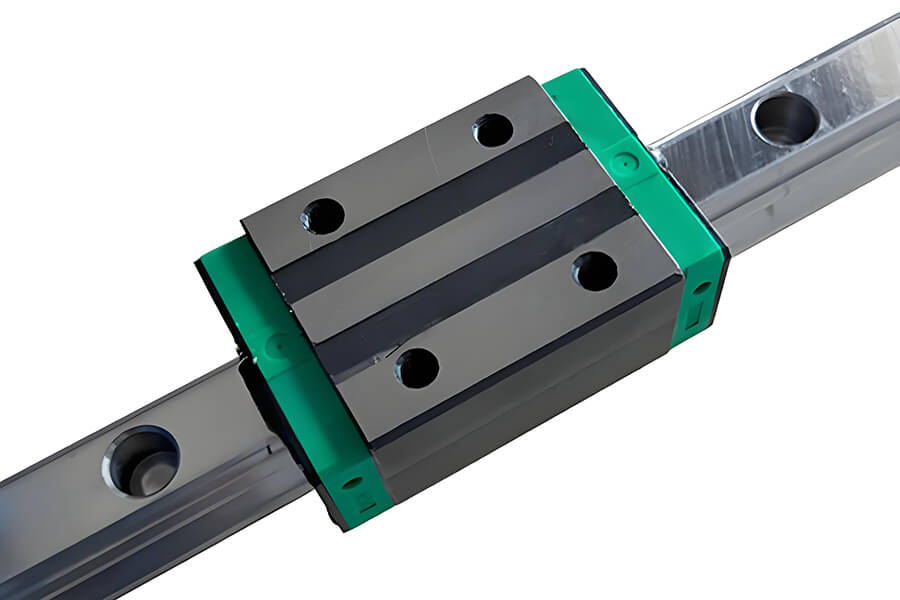

2.3. Improved Installation Accuracy

Mounting refers to how the servo ball screw is supported during operation. Precise installation is crucial to maximize the lead accuracy of the ball screw! Improper installation can cause noise, vibration, and positioning errors, and can also lead to material failure and accelerated wear. Maintaining installation accuracy requires regular inspection and repair of auxiliary components such as bearings, couplings, and nut brackets.

Summary

The precision of servo ball screw control depends not only on high-quality manufacturing processes but also on proper installation, scientific calibration, and excellent maintenance. Only by strictly controlling every step can the equipment maintain stable precision motion performance under high-speed and high-load conditions.