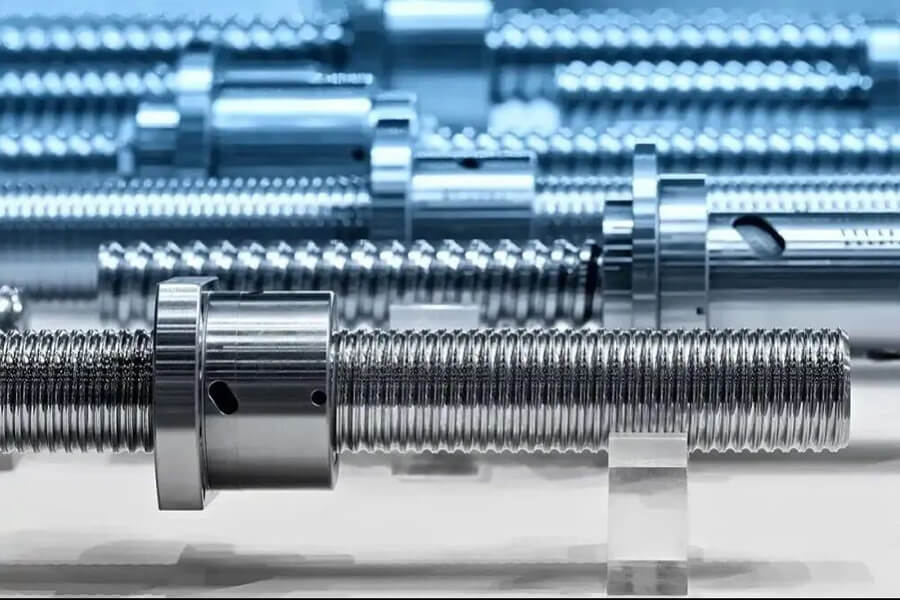

The HGR20 linear rail is a linear motion device commonly used in industrial automation and precision machinery. It is widely used for its high precision, high load capacity, and long service life. This article will provide a detailed introduction to the dimensions, specifications, and selection criteria of the HGR20 linear guide to help customers optimize their use.

1. The Cross-Sectional Code of the HGR20 Linear Rail

The cross-section of the HGR20 guide resembles a carefully designed building block, with a width of 20mm serving as its verification code. The symmetrical dovetail groove structure conceals two key dimensions:

- The height from the top of the rail to the mounting base is 15mm;

- The ball center distance is 11mm, a golden ratio.

2. Parameters and Specifications of the HGR20 Linear Rail

| Parameters | Value | Description |

| Rail Width | 20mm | HGR20 refers to a rail width of 20mm. |

| Height | 27mm | Total rail height |

| Slider Length | 70-160mm | Varies depending on slider model |

| Slider Width | 40mm | Standard Slider Width |

| Slider Height | 30mm | Standard Slider Height |

| Mounting hole spacing | 45mm | Center to center distance |

3. Why Choose This Size?

The 20mm width offers the perfect balance of precision and strength:

- Spatial Adaptability: Easily fits into small automation equipment

- Load Capacity: A single guide rail can support a dynamic load of 200kg

- Accuracy Guarantee: ±0.01mm repeatability

- Compatibility: Seamless integration with mainstream motor modules

Thus, the HGR20 linear rail is ideal for high-precision, compact equipment.

4. Selection Guide to Avoiding Pitfalls

These practical tips can help you avoid mistakes:

- Environmental Matching: For dusty environments, choose a sealed model.

- Preload Selection: For light loads, choose a standard model; for heavy loads, choose a reinforced model.

- Length Calculation: Effective Stroke + Slider Spacing (for two or more slides) + Slider Length x Number of Slider Lengths (Safety Travel at Both Ends).

- Installation Tip: The reference surface flatness must be less than 0.02mm/m.

Summary

HGR20 linear rails, due to their high load capacity, high precision, and stability, are essential components in industrial automation equipment. Understanding their dimensions and specifications not only facilitates correct selection but also improves equipment efficiency and service life. If you have any linear guide-related needs or other questions, please feel free to contact us!

FAQ

1. What Equipment is the HGR20 Linear Rail Suitable for?

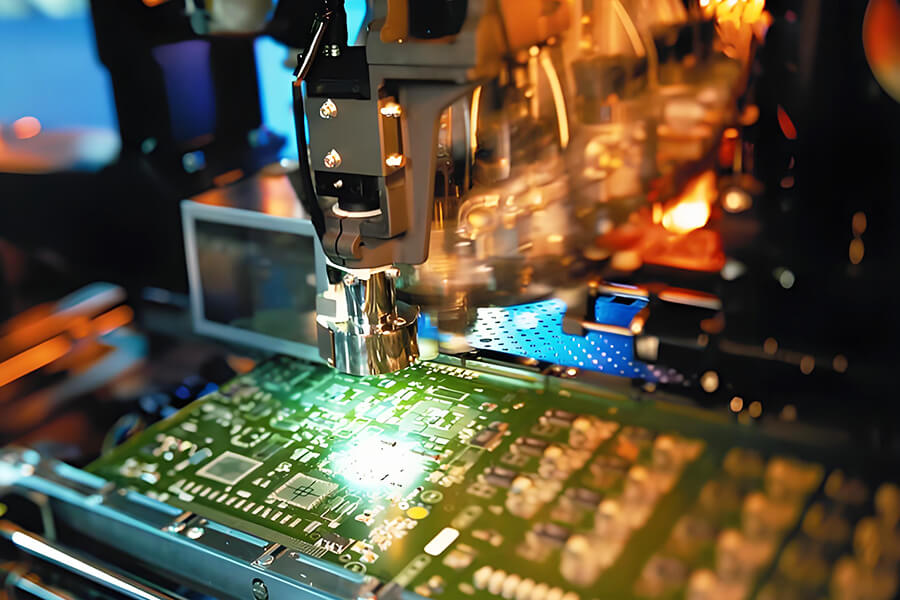

GR20 guides are primarily used in CNC machine tools, 3D printers, automated assembly lines, and other small precision machinery. They are particularly suitable for applications where space is limited but high precision and load capacity are required.

2. What is the Maximum Load Capacity of the HGR20 Guide?

The dynamic load of a single HGR20 guide rail is approximately 200 kg, and the static load is higher. The actual load needs to be calculated based on the number of slides and the mounting method.

3. What Precautions Should be Taken When Installing the HGR20 Linear Rail?

Ensure the flatness of the reference surface is less than 0.02 mm/m. Avoid overtightening during installation, lubricate regularly, and select dust-proof slides based on the environment.