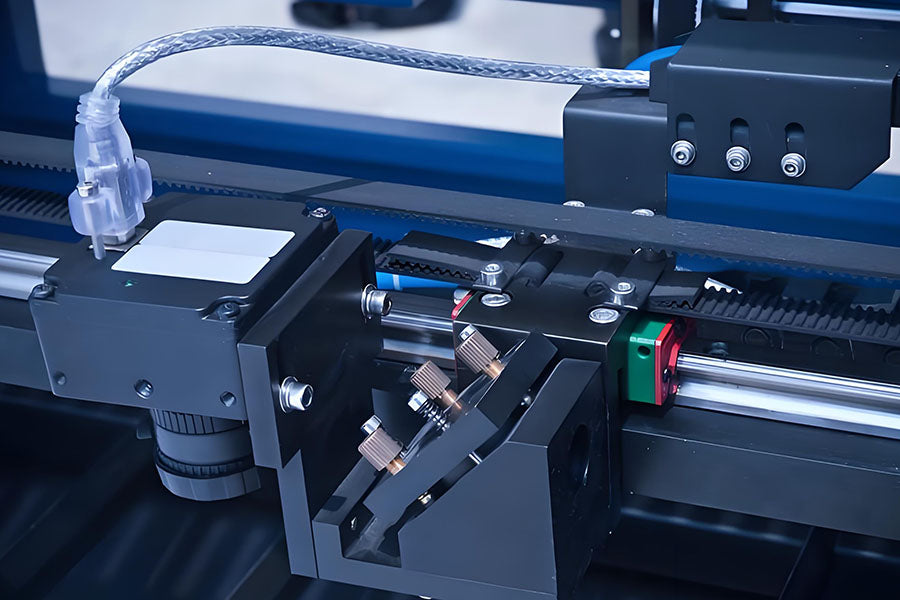

Linear guide systems are commonly used as transmission and guide components in machine tools, automation equipment, and precision instruments. Their installation accuracy directly impacts the equipment's smooth operation, machining precision, and service life. Therefore, strict adherence to specifications is crucial during installation to ensure optimal performance of the guide system.

1. Cleaning

Before installing linear guide systems, remove burrs, dirt, and impurities from the mechanical mounting surface to prevent impurities from being pressed into the track during installation and obstructing the slider's movement.

2. Leveling

The mounting surface must be level, meaning its straightness and levelness meet the equipment's requirements. If the surface is not level, the slider will tilt, affecting its motion accuracy. Use a spirit level for measurement and shims for leveling.

3. Clearance

When installing linear guide systems, ensure the clearance between the slider and the rail is uniform and meets the equipment's requirements. Excessive or insufficient clearance will affect the slider's motion accuracy and lifespan. When adjusting the clearance, use a feeler gauge to measure and adjust with the adjustment screws.

4. Tightening

When installing linear guide systems, tighten the screws between the slider and the guide rail to the specified torque. Excessive or insufficient tightening torque will affect the slider's motion accuracy and lifespan. When tightening the screws, use a torque wrench to measure and tighten to the specified torque.

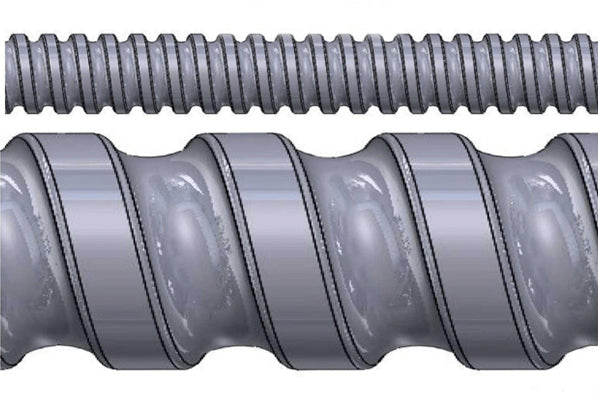

5. Lubrication

During use, linear guides must be lubricated regularly to reduce friction and wear. Lubricate with the specified lubricant and lubricate according to the specified lubrication cycle.

6. Dust Prevention

During use, measures must be taken to prevent dust and impurities from entering the slider to avoid affecting its motion accuracy and lifespan. Dust protection can be achieved with dust covers or dust shields.

7. Inspection

During use, linear guide systems must be regularly inspected for motion accuracy. Any deviations must be adjusted promptly. Measuring tools can be used for measurement.

Note

1. Assembly must strictly adhere to the principle of precision. Slide replacement should not affect the machine's operating accuracy. Therefore, extreme caution must be exercised when replacing machine parts, strictly following the manufacturer's technical instructions. Installation angle measurements should be particularly careful.

2. The slides on both sides of the guide rail should be identical to the original slides. In any case, ensure that both sides of the guide rail use the same matching pattern. Any deviation will increase the amount of play during stone engraving, leading to frequent machine failures.

Summary

Precise installation of linear guide systems is fundamental to ensuring the efficient operation of machine tools and automated equipment. Strictly following the above precautions can effectively prevent premature wear, abnormal operation, and reduced accuracy, thereby enhancing the overall performance and service life of the equipment.