In modern manufacturing, the precision and efficiency of CNC machine tools are crucial. We often hear that CNC machining centers are differentiated by hard guideways and linear rails. This article will delve into the characteristics, advantages, and disadvantages of these two types of guideways to help you choose the right guideway for your CNC machine.

1. What are Hard Guideways?

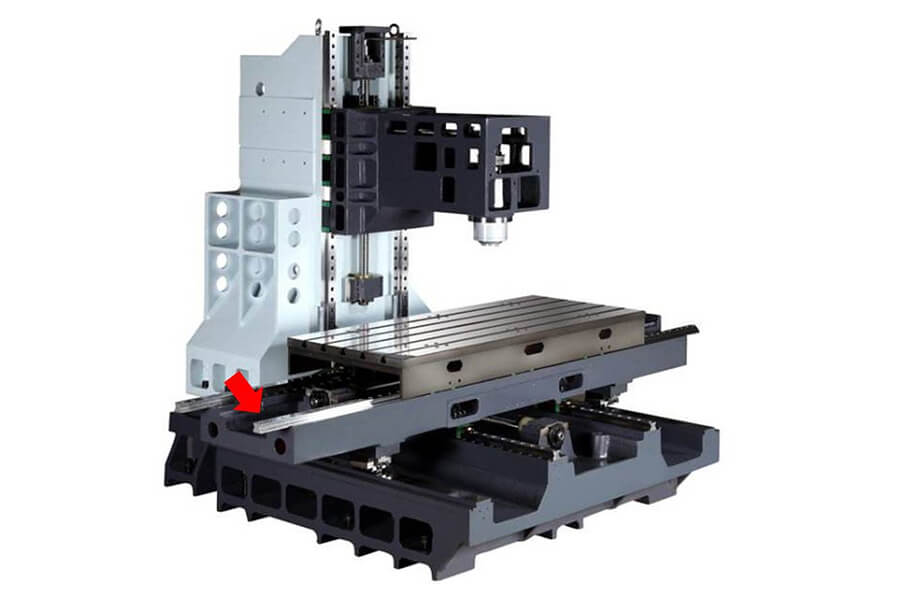

Hard guideways refer to guideways in which the guideway and machine bed are integrally cast, with the guideway then machined from the casting. This means the guideway shape is cast onto the machine bed, then hardened and ground to create the guideway. There are also cases where the machine bed and guideway are not necessarily integral, such as inlaid steel guideways, which are machined and nailed to the machine bed.

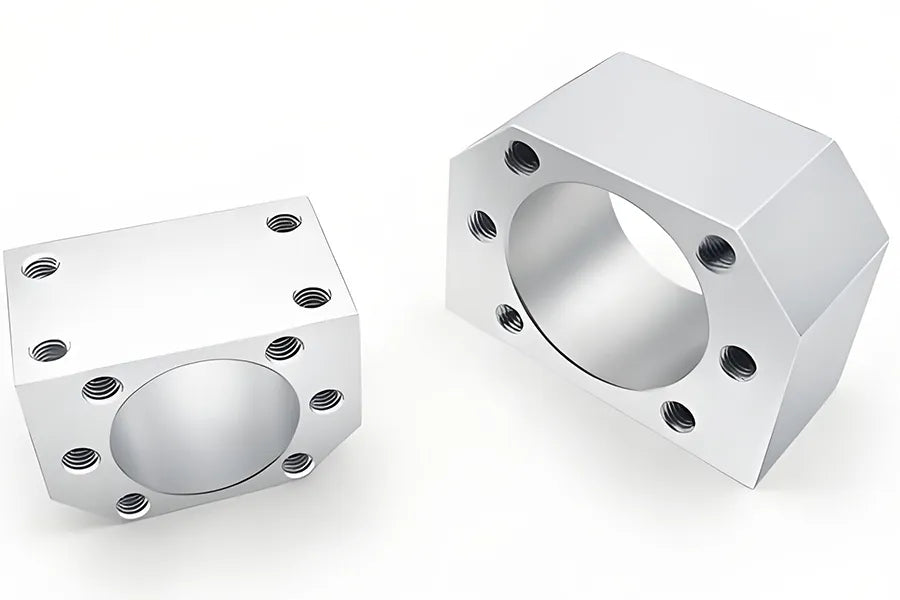

2. What are Linear Rails?

Linear rails typically refer to rolling guides, the type commonly used in linear modules in the machine tool industry. We often refer to these components as "linear guides." Linear guides consist of two parts: the guideway and the slider. The slider contains internally circulating balls or rollers, and the guideway length can be customized. It is a modular component, a standardized, serialized, standalone product manufactured by specialized manufacturers. It can be installed on machine tools and removed and replaced when worn.

3. Linear Guide Features

- Low Friction

Linear rails use rolling elements (such as balls or rollers), which have a low coefficient of friction and smoother motion.

- High Precision

Preloaded linear guides achieve zero backlash and offer high dynamic and static accuracy, making them suitable for precision machining.

- Long Service Life

Compared to hard rails, linear guides have a significantly longer service life and require less maintenance.

- High Cost

High-precision linear rails are typically more expensive, increasing the overall cost of the machine tool.

- High Maintenance Requirements

Linear rails require regular lubrication and maintenance to ensure proper operation and extend their service life.

Linear guides are suitable for high-speed machine tools, enabling high-speed cutting and are particularly well-suited for machining small precision molds and high-efficiency machining centers.

4. Key Features of Hard Rails

- High Load Capacity

Hard rails can withstand large loads, making them suitable for heavy-duty machining and high-intensity working environments.

- Rigidity and Vibration Resistance

Hard rails have a larger sliding contact surface and excellent rigidity, effectively resisting vibration and stabilizing the machining process.

- High Wear Resistance

The hardened surface offers excellent wear resistance, maintaining accuracy over a longer period of time.

However, hard rails also have their drawbacks:

- High Friction

Due to the large contact surface, hard rails operate in a dry friction mode, resulting in high frictional resistance and limited speed.

- Slippage

During low-speed operation, slippage may occur, leading to unstable motion and affecting machining accuracy.

- High Maintenance Requirements

Maintaining machine tool rails is paramount. Inadequate lubrication can lead to rail burnout or excessive wear, both of which can be detrimental to machine tool accuracy.

Hard rails are generally suitable for heavy cutting, large molds, high-hardness workpieces, and workpieces with moderate precision requirements.

Conclusion

When choosing between hard rails and linear rails, you need to consider a variety of factors, including the specific application requirements, machining type, load requirements, accuracy standards, and budget. Hard rails are suitable for environments requiring heavy loads and high wear resistance, while linear guides are more suitable for high precision and lightweight requirements.