In modern industrial production, the advancement of automation and robotics is continuously driving improvements in manufacturing efficiency. Within this process, racks, as fundamental mechanical transmission components, play an indispensable role in precision motion, positioning control, and power transmission. This article will begin with the basic concept of gear racks and explore their key applications and advantages in automation and robotics.

1. Basic Concepts of Gear Racks

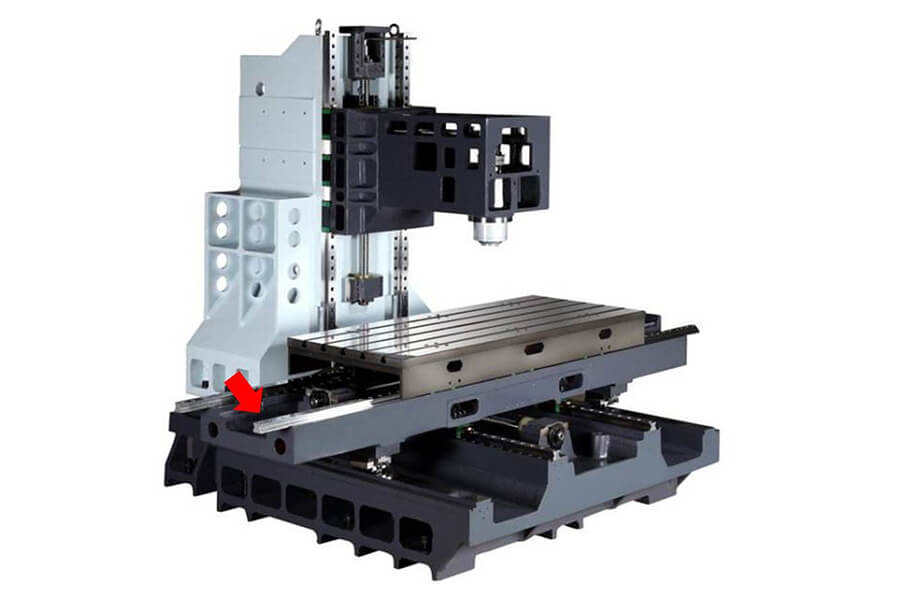

A rack is a mechanical component that converts rotational motion into linear motion. It is typically used in conjunction with a pinion, achieving linear displacement through meshing. Gear racks can be categorized into two types: spur racks and helical racks.

- Spur racks: Their tooth profile is simple, resulting in low manufacturing costs and suitable for medium-to-low speed and low-load applications.

- Helical racks: Their tooth surfaces are angled relative to the gear, resulting in smooth meshing and high load capacity, making them suitable for high-speed or high-precision applications.

Gear Racks are typically made of high-strength steel, alloy steel, or engineering plastics. Depending on the application environment, they can be treated with wear-resistant or corrosion-resistant finishes to ensure long-term, stable operation.

2. Applications of Gear Racks in Automation

Automated production lines place extremely high demands on mechanical motion precision and repeatability. Racks are primarily used in automation equipment in the following areas:

2.1 Precision Linear Motion Control

In automated assembly, testing, and packaging equipment, the accuracy of linear motion directly impacts product quality. Racks, used in conjunction with servo motors or stepper motors, can achieve high-precision and repeatable positioning, ensuring stable and efficient production processes. For example, automated assembly equipment for electronic components requires gear racks to achieve micron-level linear motion to ensure accurate placement of each component.

2.2 High-Speed Handling and Transport

Modern automated logistics systems, such as conveyor robots, AGVs (Automated Guided Vehicles), and warehouse handling systems, require fast and stable material transport. Rack drives, with their high rigidity and excellent meshing properties, maintain smooth motion while maintaining speed, reducing mechanical vibration and error accumulation.

2.3 Power Transmission for Heavy-Load Operations

In automated production equipment, certain workstations may require handling heavy materials. Racks can withstand heavy loads and, when combined with high-power motors, achieve heavy-load linear motion, ensuring long-term stability and reliability.

3. Rack Applications in Robotics

Robotics technology places higher demands on motion precision, flexibility, and reliability. Rack applications in robotic systems primarily include:

3.1 Linear Joints in Robotic Arms

In industrial robotic arms, some joints utilize a rack-and-pinion structure to convert the power of a rotary motor into linear motion, enabling grasping, handling, or welding. This structure offers a compact footprint, high load capacity, and precise motion, making it ideal for multi-degree-of-freedom robotic designs.

3.2 Chassis Drives in Mobile Robots

Mobile robots, automated guided vehicles (AGVs), and unmanned transport vehicles typically utilize rack drives for chassis motion control. By meshing the rack with the drive wheels, the robot can achieve high-precision positioning and navigation in confined spaces, while reducing errors caused by tire slip and improving the reliability of autonomous movement.

3.3 Precision Operations in Collaborative Robots (Cobots)

Collaborative robots emphasize safety and precision. In the cobot's end effector, a rack provides precise and stable linear motion, enabling the robot to perform delicate assembly, inspection, or medical procedures. It also provides rapid feedback when encountering unusual resistance, ensuring safe operation.

4. Advantages of Racks in Applications

Compared to other linear drive methods (such as ball screws and linear guides), racks offer multiple advantages in automation and robotics:

- High rigidity: Gear racks have a large meshing area, can withstand large loads, and are suitable for heavy-duty applications.

- High transmission efficiency: Low mechanical loss and fast motion response make them suitable for high-speed applications.

- Simple structure and easy maintenance: Gear racks are easy to install and replace, resulting in low maintenance costs.

- Long strokes possible: By extending the rack length, mechanical motion can cover a wider range, eliminating space constraints.

- Relatively low cost: For long strokes or heavy-duty applications, rack solutions are generally less expensive than screw or hydraulic systems.

5. Application Examples of Racks

Industrial assembly lines: Automated assembly robots use racks for linear positioning, improving assembly speed and accuracy.

Warehousing and logistics: In automated warehouses, racks drive elevators for efficient cargo handling.

Precision testing equipment: Gear Racks combined with servo systems achieve highly repeatable motion for precision testing instruments. Laser cutting and welding robots: Racks ensure that the tool or welding torch moves along a specified linear trajectory, ensuring machining accuracy.

Conclusion

Gear racks, as crucial mechanical components for converting rotary motion into linear motion, have extensive applications in automation and robotics. They not only enable high-precision and efficient linear motion but also demonstrate their advantages in heavy-load, high-speed, and long-travel scenarios.