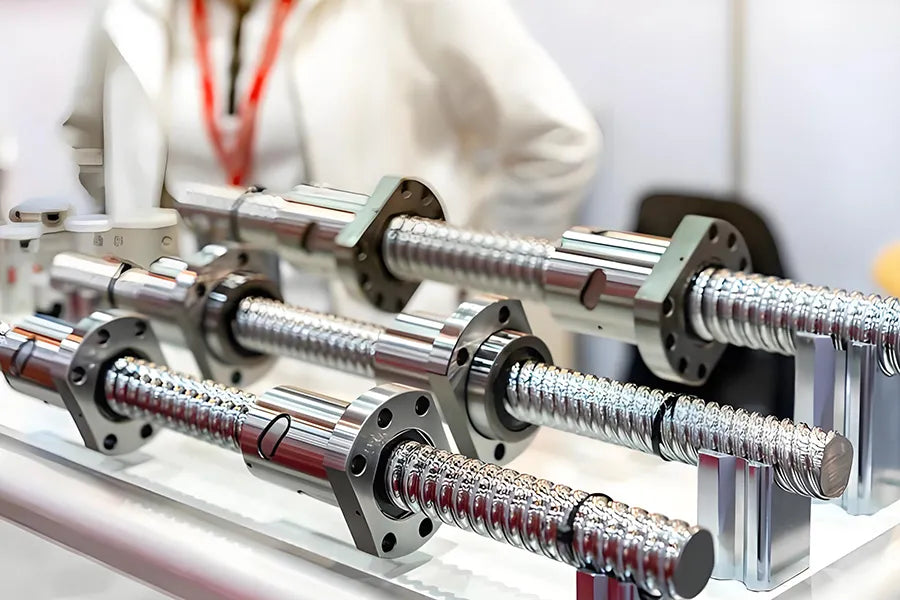

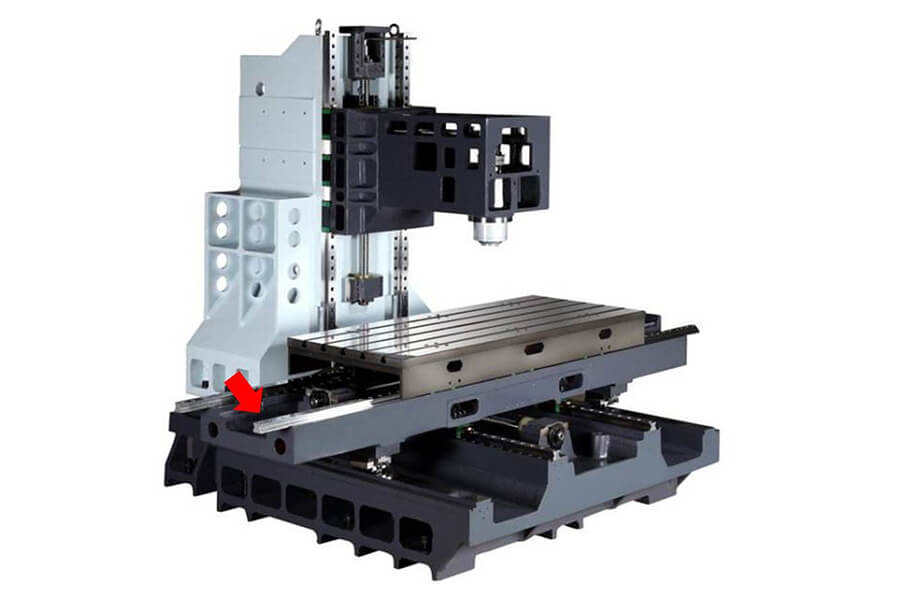

In modern precision machinery and automation equipment, lead screws, as key linear drive components, are widely used in CNC machine tools, industrial robots, and automated production lines. In lead screw systems, the choice of nut type is crucial for optimizing equipment performance, service life, and application scenarios. This article will detail several common lead screw nut types and analyze their structural characteristics and application advantages.

1. The Importance of Lead Screw Nuts

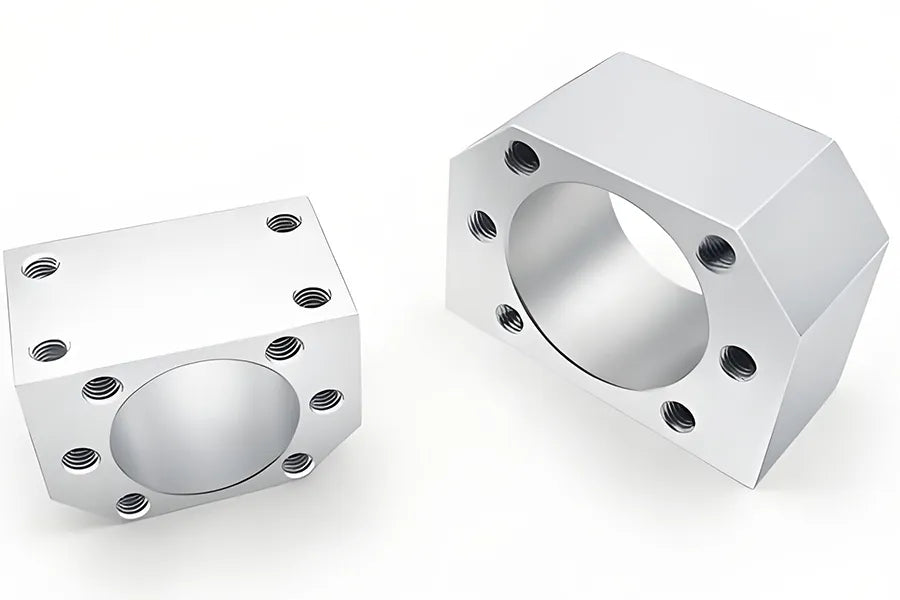

The nut is a core component of the lead screw system, forming a rolling pair with the lead screw. Steel balls continuously circulate between the two, ensuring smooth transmission. Different types of nuts vary in their circulation method, load capacity, lead size, operating noise, and applicable operating conditions.

Choosing the right nut not only improves equipment machining accuracy and operating efficiency, but also effectively extends service life and reduces maintenance costs.

2. Common Lead Screw Nut Types

1. K, NU, and NI Nuts

K, NU, and NI nuts typically feature an internal recirculation design. Their operating principle is that the steel balls follow the inverter raceway, diagonally crossing the lead screw teeth and returning to the starting point. One revolution constitutes one cycle, and a nut typically includes multiple recirculations.

Features and Advantages:

- Suitable for small-size, small-lead designs;

- Relatively compact, suitable for equipment with limited installation space;

- Multi-cycle design enhances load capacity and stability.

Typical Applications

Small precision equipment, laboratory instruments, automatic dispensing machines, and other applications requiring small strokes and high precision.

2. Y- and E-Type Nuts

Y- and E-type lead screw nuts use an end-plug circulating structure. The steel ball returns to the starting point of the cycle through inverters at both ends and a return channel inside the nut housing. A cycle typically consists of several revolutions, and a nut typically has two cycles.

Features and Advantages:

- Suitable for designs with larger leads, enabling faster linear speeds;

- Smooth rolling conditions, low friction, and smoother operation;

- Suitable for medium- and high-speed operation, balancing load and efficiency.

Typical Applications

CNC machine tool feed systems, automated production lines, and transmission equipment, particularly suitable for work environments requiring medium- to high-speed and smooth transmission.

3. A and S-Type Nuts

Both A- and S-type lead screw nuts utilize an end-plug circulation structure, but unlike the Y/E-type, their design generally consists of only a single loop. The steel balls circulate through an inverter and a return channel, creating a simple and efficient transmission mode.

Features and Advantages:

- Single-loop design with a short rolling path and quieter operation;

- Supports high-speed operation, meeting high-speed operating conditions;

- Suitable for applications requiring high noise control and speed.

Typical Applications

Semiconductor manufacturing equipment, medical instruments, automated testing equipment, etc., particularly suitable for use in high-speed, low-noise environments.

3. Nut Circulation Method

The performance and application differences of lead screw nuts primarily stem from their ball circulation method. There are three common circulation methods: internal circulation, external circulation, and end-plug circulation.

3.1 Internal Circulation

The steel balls pass through an inverter inside the nut, crossing the screw thread crest and returning to the starting point of the loop. Its compact structure and small outer diameter (which takes up less space) make it suitable for small lead lengths.

3.2 External Circulation

The steel balls return to their origin through an external circulation tube, creating a clear circulation path. This economical series is suitable for large leads and heavy loads.

3.3 End-Plug Circulation

The steel balls circulate through inverters and return channels mounted on both ends of the nut. This method offers smooth rolling, low noise, and is suitable for medium- and high-speed operation, making it a widely used circulation structure. The Silent High-Speed series is suitable for high-speed feeds.

Different circulation methods determine differences in lead screw nut speed, noise, load capacity, and size, so selection requires comprehensive consideration based on the specific application scenario.

Conclusion

Despite their small size, lead screw nuts play a crucial role in precision motion systems. By gaining a deeper understanding of the structural characteristics and application advantages of different nut types, companies can more effectively select the appropriate product, thereby improving the accuracy, efficiency, and reliability of the overall system.