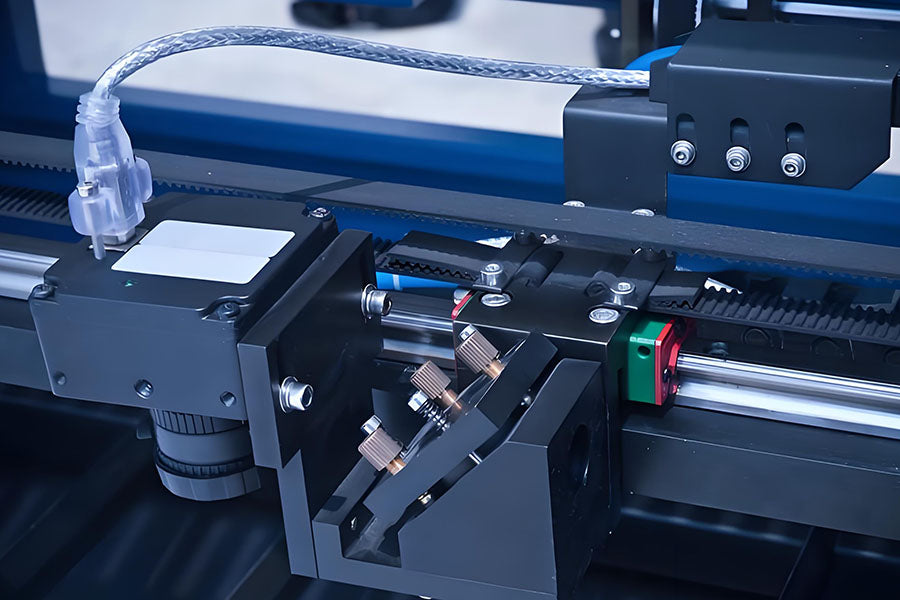

In the industrial field, linear guides are a common mechanical device used to achieve smooth linear motion. Due to long-term use, improper maintenance, or other factors, CNC linear guide rails may experience various faults. This article details possible faults encountered by linear guide sliders and provides corresponding troubleshooting and repair methods.

1. Increased Sliding Resistance

Symptoms: The linear guide experiences a noticeable increase in sliding resistance, resulting in jerky motion.

Cause: This may be due to accumulation of dust, oil, or wear on the guide rail surface.

Troubleshooting: Clean the guide rail surface with a detergent and a soft cloth. If cleaning is ineffective, the guide rail may need to be replaced.

2. Abnormal Noise

Symptoms: The CNC linear guide rail produces abnormal noise during movement, affecting normal operation.

Cause: This may be due to excessive clearance between the guide rail and slider, or the ball bearing inside the slider is dislodged or damaged.

Troubleshooting: Check whether the clearance between the guide rail and slider meets the specified requirements. If the clearance is excessive, adjust or replace the component. If the ball bearing is the problem, replace it and ensure the new ball bearing is properly installed.

3. Unstable Movement

Symptoms: The CNC linear guide rail becomes unstable during movement, potentially vibrating or deviating from its intended trajectory.

Cause: This could be caused by foreign matter, damaged balls, or threads on the guide rail. Troubleshooting: Clear the guide rail of any foreign matter and ensure it is unobstructed. Inspect and replace any damaged balls. If the threads are defective, the entire guide rail assembly may need to be replaced.

4. Guide Rail Deformation

Symptoms: The guide rail of the linear guide slider is bent, twisted, or deformed.

Cause: This could be caused by excessive load, excessive impact, or improper installation. Troubleshooting: Check whether the load exceeds the guide rail's load capacity and reduce the load appropriately. Ensure proper installation, such as using appropriate bolts and support structures. If the guide rail is severely deformed, it may need to be replaced.

5. Insufficient or Excessive Lubrication

Symptoms: The CNC linear guide rail is insufficiently or excessively lubricated during movement, resulting in increased friction or lubricant leakage.

Cause: This could be caused by improper lubrication cycles, incorrect lubricant selection, or damaged lubricant seals. Troubleshooting: Determine the appropriate lubrication cycle and lubricant type based on operating requirements and working environment. Check the integrity of lubricant seals and replace if necessary.

Summary

CNC linear guide rails are core components of CNC equipment, and their stability and precision are crucial to the performance of the entire machine. Proper use, timely maintenance, and thorough troubleshooting can effectively extend the life of the guides, minimize downtime losses, and ensure long-term stable operation of the equipment.