As industrial equipment continues to demand higher precision, higher speeds, and higher reliability, flex disc couplings, with their unique structure and superior performance, are becoming the preferred choice in many industries. This article will provide a comprehensive introduction to flex disc couplings from various perspectives.

1. Working Principle

When two shafts experience axial, radial, or angular misalignment during operation, the diaphragm undergoes slight elastic deformation, thereby eliminating misalignment and maintaining stable torque transmission. This method eliminates the use of lubricants, reduces operating noise, and reduces maintenance.

2. Applications

Flex disc couplings are widely used in shaft transmission systems in various mechanical devices, such as pumps (especially boiler feed pumps), fans, compressors, cement machinery, and steam turbines. Due to their excellent performance, they have become a vital transmission component under demanding operating conditions.

3. Structural Features

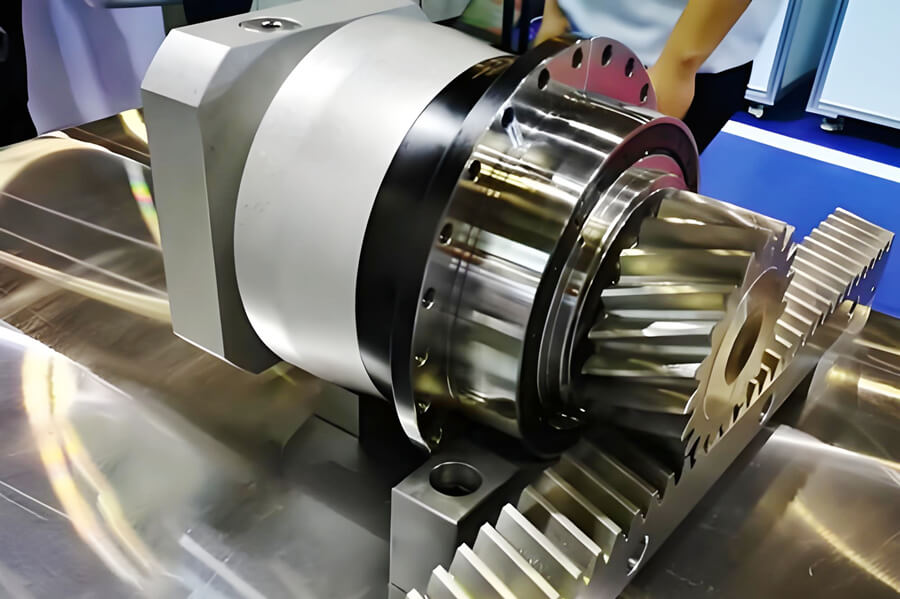

Flex disc couplings consist of several stacked stainless steel sheets (diaphragms) secured between two coupling halves using staggered high-strength bolts. Diaphragms can be categorized as either connecting rod or single-piece types, depending on their structure. Each diaphragm set is typically composed of multiple stacked diaphragms.

This type of coupling relies on the elastic deformation of the diaphragms during operation to compensate for relative displacement between the two shafts. It is a high-performance metal flexible coupling with the following features:

- No lubrication required: Operation requires no oiling, making it clean and environmentally friendly.

- Compact structure: Lightweight and easy to install.

- High strength and long life: The stainless steel diaphragm exhibits excellent fatigue resistance, ensuring long-term stable operation.

- Zero-clearance transmission: No rotational backlash, resulting in high transmission accuracy.

- Environmentally resistant: Unaffected by temperature and oil contamination, it is acid-, alkali-, and corrosion-resistant, making it suitable for high-temperature, high-speed, and corrosive media applications.

4. Working Principle

The working principle of a flex disc coupling is relatively straightforward:

- Torque is first input from the driving coupling half;

- Then it is transmitted to the front diaphragm set via high-strength bolts evenly distributed along the circumference.

- The diaphragm set elastically deforms and transmits torque to the intermediate sleeve.

- Finally, the torque is transmitted to the driven coupling half via the rear diaphragm set and high-strength bolts. The whole process realizes the effective transmission of torque and energy transfer, while allowing a certain amount of deviation.

5. Main Characteristics of Flex Disc Coupling

- It has a strong ability to compensate for the misalignment of the two axes. Compared with the gear coupling, the angular displacement can be twice as large. The reaction force during radial displacement is small, the flexibility is large, and a certain amount of axial, radial and angular displacement is allowed.

- It has a significant shock absorption effect, no noise, and no wear.

- It can adapt to high temperature (-80+300) and harsh environment, and can operate safely under shock and vibration conditions.

- The transmission efficiency is high, up to 99.86%. It is particularly suitable for medium and high speed high power transmission.

- It has a simple structure, light weight, small size, and easy installation and disassembly. It can be installed and disassembled without moving the machine (referring to the type with intermediate shaft), and no lubrication is required.

- It can accurately transmit the speed, run without slip, and can be used for the transmission of precision machinery.

Summary

Flex disc couplings, with their high torque transmission capacity, excellent compensation performance, and maintenance-free design, have become an indispensable component in modern industrial equipment. They demonstrate stable and reliable performance in high-end applications such as petrochemicals, power generation, and aerospace. With the continuous advancement of materials science and manufacturing processes, the application scope of flex disc couplings will continue to expand, providing more efficient, stable, and long-lasting solutions for mechanical transmission systems.