Linear guides support and guide moving parts in a given direction. To choose the right linear guide for the right situation, design engineers need to understand the advantages and performance of different guides and make the right choice.

1. Types of Linear Guides

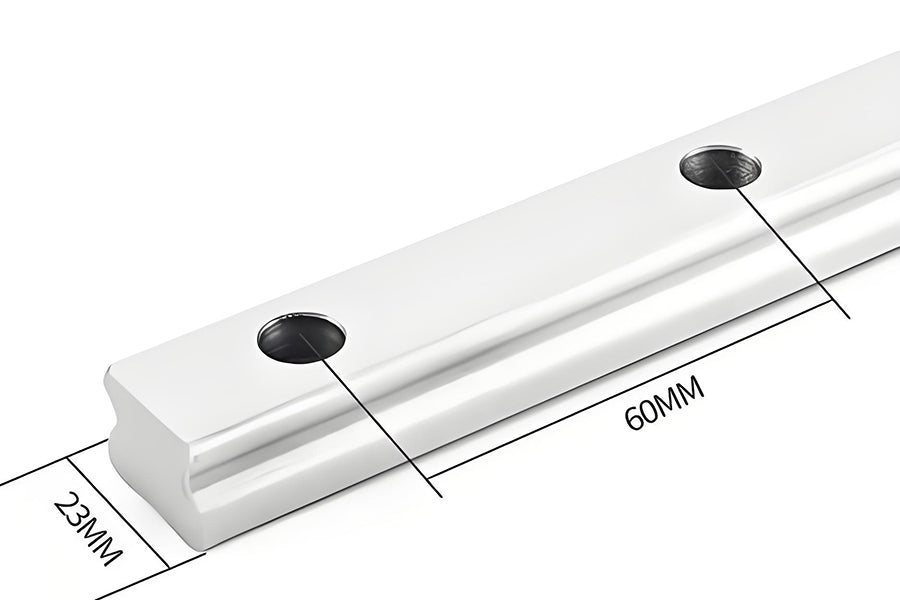

Square Linear Guides

Square sliders and square guides are used together, creating a square appearance. Considering friction and load capacity, square guides rely on contact friction between the guide rail and the slider. They offer high friction, uniform load, and require frequent lubrication.

Circular Linear Guides

Used for linear bearings and linear shafts. They have a cylindrical shape and can be installed in round holes. They can also be used with sliders for flat mounting. Circular guides are more convenient to install and use, saving space.

2. Guide Rail Selection

When choosing between circular and square linear guides, factors such as load capacity, accuracy, rigidity, and finish should be considered.

Square Linear Guides

Square guides are typically used in the machine tool industry, which requires high load capacity, rigidity, and accuracy. However, even after meeting the above requirements, it can be difficult to meet other requirements, such as high installation requirements, high initial cost, and high maintenance costs.

Circular Linear Guides

Circular guides demonstrate their advantages in this regard. They can operate smoothly even when installed on less-smooth surfaces. Circular guides are generally faster and smoother to install and operate than square guides. In summary, the optimal solution is to choose based on actual needs.

3. Performance Comparison

| Performance | Square Linear Guide | Round Linear Guide |

| Load Capacity | High, can withstand radial, axial and overturning moments | Medium, mainly withstands radial loads |

| Precision | High, suitable for precision machining | Medium, suitable for general guiding needs |

| Motion rigidity | High | Low |

| Installation Requirements | High precision, strict parallelism requirements | Flexible installation, low base flatness requirements |

| Lifespan | Long | Medium |

| Applicable Environments | High-precision machine tools, CNC machines, and automation equipment | Simple machinery and light-load equipment |

Summary

Round and square linear guides each have their advantages. Square guides are suitable for applications requiring high precision, high load capacity, and high rigidity, while circular guides, with their simple structure and flexible installation, are suitable for lighter loads and space-constrained applications. Understanding the differences and applications of these two types of guides will help you make informed decisions in equipment design and selection, improving the performance and lifespan of mechanical systems.