Miniature linear guides are precision positioning and movement devices, consisting of a guide rail and a slider. They achieve efficient and stable movement through a unique ball or roller structure.

1. Applications of Miniature Linear Guides in Electronic Equipment Manufacturing

1.1 Automated Assembly Lines

- Part Positioning and Assembly

Miniature linear guides, with their high precision, ensure accurate positioning of parts during assembly. This significantly improves assembly accuracy and efficiency, reducing assembly errors caused by inaccurate positioning.

- Resource Saving

By cooperating with other automated devices, miniature linear guides play a crucial role in efficient and accurate assembly, thereby saving human resources and time costs.

1.2 Automatic Inspection Equipment

Fine Inspection:** Combining inspection instruments with miniature linear guides enables fine inspection of electronic products. The high precision and stability of miniature linear guides ensure accurate inspection results, contributing to improved product quality.

* **Increased Inspection Efficiency:** The high-speed movement characteristics of miniature linear guides allow inspection equipment to complete inspection tasks more quickly, improving overall production efficiency.

1.3 Robot Operation

Precise Movement and Positioning: Robots can move and position precisely on miniature linear guides to complete different processes, such as soldering and surface mounting. This precision ensures consistency and stability in the production process.

Improved Production Efficiency: The combination of robots and miniature linear guides enables automated production, significantly improving efficiency. Simultaneously, it reduces human error and improves product quality.

1.4 Copper Foil Substrate Manufacturing

Copper foil substrates are a crucial basic material for manufacturing printed circuit boards. They are laminated with copper foil using an adhesive sheet made by impregnating insulating paper, fiberglass cloth, or other fibrous materials with resin, and then formed under high temperature and pressure. The application advantages of Simkawa ball-type linear guides include ease of installation, ensuring assembly accuracy, and enabling flexible assembly.

1.5 Surface Mount Technology

SMT involves printing solder paste onto fixed points on a PCB circuit board. Resistors, capacitors, and other components are mounted on the surface of the circuit board using machinery and equipment. The circuit board is then baked at high temperature to cure the solder paste, firmly soldering the components to the circuit board to form a complete circuit board assembly. Simkawa Ball Screw Linear Guides/Roller Screws: High-precision ball screws paired with linear guides enable high-speed positioning, ensuring fast and precise placement.

1.6 Adhesive Dispensing

Dispensing is a process of applying, potting, or dripping electronic adhesives, oils, or other liquids onto products to achieve functions such as adhesion, potting, insulation, fixation, and surface smoothing. Simkawa miniature linear guides offer advantages such as smooth operation for precise movement, avoiding excess adhesive on the product and affecting quality.

1.7 Optical Inspection

Optical inspection is a high-speed, high-precision optical imaging inspection system that uses machine vision as the inspection standard technology. Simkawa miniature linear guides offer advantages such as up to 20,000 kilometers of maintenance-free operation.

2. Advantages

The popularity of miniature linear guides in electronic equipment manufacturing stems primarily from their unique advantages:

2.1 Innovative Anti-Ball Drop Design

The new generation of steel ball retainer systems employs a unique structural design to firmly secure the steel balls, preventing them from falling out. Therefore, there is no need to worry about ball drop during assembly, allowing for easy and quick installation.

2.2 Maintenance-Free for Up to 20,000 km

For optimal maintenance-free operation, all miniature sliders are factory pre-lubricated and equipped with self-lubricating oil reservoirs. This ensures the grease inside the slider remains in optimal condition, reducing friction and wear, ensuring proper lubrication within the system, and extending service life.

2.3 Excellent Dust Protection

Optimized seals effectively prevent dust from entering the slider, providing unparalleled dust protection.

2.4 Quiet and Smooth Precision Transmission

A unique ball bearing circulation system and steel plate retainer effectively reduce friction, achieving ultra-smooth slider operation and reducing noise by up to 50%, creating a quiet and comfortable working environment suitable for office environments, medical, and laboratory applications.

2.5 Wear Resistance and Corrosion Resistance

Through special treatment, miniature linear guides maintain stable performance over extended use, improving equipment reliability.

Summary

As electronic equipment manufacturing continues to evolve towards higher precision, higher automation, and higher integration, the application scope and importance of miniature linear guides will continue to expand. They not only support the stable operation of electronic manufacturing equipment but also directly impact product quality, production efficiency, and enterprise competitiveness. If you have any related needs, please feel free to contact us!

FAQ

1. What are the different types of micro linear guide?

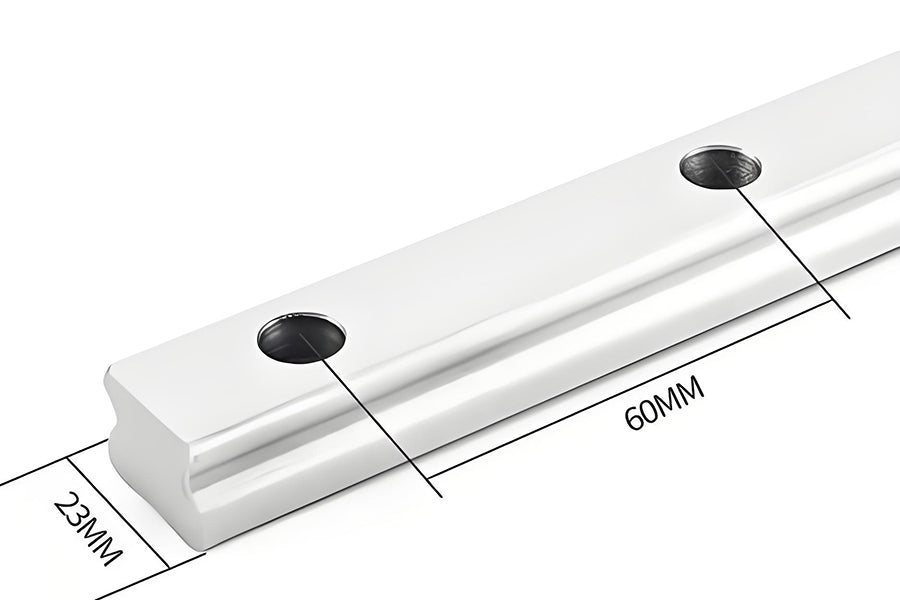

Simkawa offers two series of miniature linear guides: LGN and LGW. The LGN series includes miniature linear guides, while the LGW series features a wider miniature design. These are suitable for semiconductor manufacturing equipment, printed circuit board (PCB) IC assembly equipment, medical equipment, and other small linear sliding devices.

2. What are the differences between miniature linear guides and standard linear guides?

Miniature linear guides are smaller and lighter than ordinary guides, making them more suitable for high-precision equipment such as electronic devices and semiconductor devices; standard guides are more suitable for medium to high loads and scenarios with sufficient structural space.

3. Does a Micro Linear Guide require lubrication?

Yes. Even micro linear guides must be lubricated regularly to reduce wear and extend service life. For some applications, low-volatility or clean greases may be preferred.