In modern manufacturing, machine tools are key processing equipment. Their precision, stability, and efficiency directly determine product quality and production efficiency. To achieve precise motion transmission and control, high-performance couplings are often required in machine tool transmission systems. Metal bellows couplings, with their zero backlash, high torsional stiffness, and excellent compensation capabilities, have become an indispensable component for precision transmission in the machine tool industry.

1. What is a Metal Bellows Coupling?

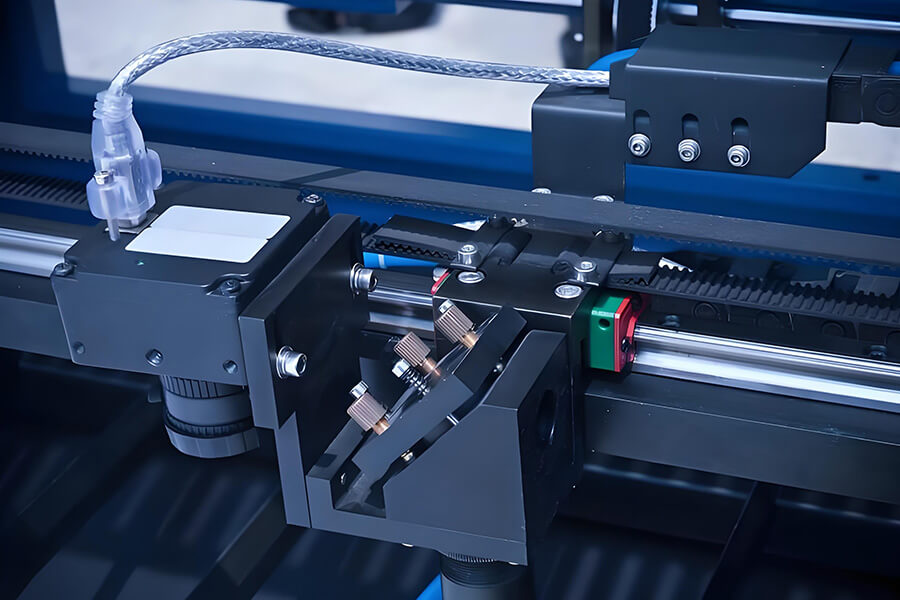

A thin-walled, corrugated tube (bellows) is directly welded or bonded to the two coupling halves to transmit motion. This coupling features a simple structure, small dimensions, easy processing and installation, and high transmission accuracy. It is primarily used in low-power precision machinery and control mechanisms that require a compact design and high transmission accuracy.

2. Transmission Characteristics and Challenges in the Machine Tool Industry

Machine tools have several significant characteristics during processing:

2.1 High Precision Requirements

Machine tool processing accuracy typically reaches micron levels, and transmission systems must maintain zero backlash and extremely high synchronization.

2.2 High-Speed Operation

Modern CNC machine tools often require high-speed cutting, resulting in high spindle and feed shaft speeds. This places stringent demands on the dynamic balance and rigidity of the coupling.

2.3 Large Load Variation

Cutting forces fluctuate during machining due to factors such as tool feed and material hardness. The coupling must be able to withstand transient impact torque.

2.4 Thermal Expansion and Installation Deviation

Long-term machine tool operation can cause thermal expansion, and the shaft system may also have minor installation errors, requiring the coupling to have a certain degree of compensation capability.

3. The Role of Metal Bellows Couplings in Machine Tools

3.1 Bells Couplings Provide Backlash-Free Transmission

During operation, the bellows and hub are tightly connected, eliminating any gaps. This ensures backlash-free transmission, improving transmission accuracy and stability.

3.2 Bells Couplings Provide Vibration and Shock Resistance

The bellows' elastic properties enable them to absorb vibration and shock energy, reducing their impact on the transmission system and protecting the equipment's normal operation.

3.3 High Torque Transmission Capacity of Bellows Couplings

Despite their relatively compact structure, bellows couplings offer high torque transmission capacity, meeting the transmission requirements of most mechanical equipment.

3.4 Improved Dynamic Response

Due to their light weight and low moment of inertia, metal bellows couplings can quickly respond to acceleration and deceleration commands from the servo system, making them ideal for high-speed interpolation machining on machine tools.

4. Typical Application Scenarios

Bells couplings are widely used to connect the spindle and feed shaft in CNC machine tools, machining centers, and other machine tools, ensuring machining accuracy and stability. Bellows are typically made of metal materials such as stainless steel and nickel, which offer excellent elasticity and corrosion resistance, ensuring the coupling's service life.

During the manufacturing process, the bellows require precise machining and forming to ensure uniform wall thickness and high dimensional accuracy. Furthermore, the machining accuracy of the hub also significantly impacts the coupling's performance.

5. Selection and Usage Considerations

5.1 Select Based on Torque and Speed

Ensure that the rated torque and maximum speed exceed the actual requirements of the machine tool, while allowing for a safety factor.

5.2 Matching the Shaft Diameter and Mounting Method

Select a suitable clamping or keyway mounting method to ensure a precise fit with the shaft.

5.3 Control Installation Errors

Although metal bellows coupling have compensation capabilities, initial deviation should be minimized to extend their lifespan.

5.4 Prevent Overload and Impact

Avoid frequent sudden stops and overload cutting during operation.

5.5 Perform Regular Inspections

After extended use, inspect the bellows for cracks or looseness, and replace them if necessary.

Summary

In the machine tool industry, metal bellows couplings, with their high precision, zero backlash, high torsional stiffness, and compensation capabilities, play a vital role in ensuring machining accuracy, improving transmission stability, and protecting equipment.

You may also be interested in the following article:

FAQ

1. What is the difference between metal bellows couplings and conventional flexible couplings?

Conventional flexible couplings are often made of non-metallic materials such as rubber and elastomers, offering strong compensation capabilities but lower rigidity. Metal bellows couplings utilize stainless steel bellows, offering higher torsional stiffness and zero backlash, making them ideal for precision transmission applications.

2. How much misalignment can a metal bellows coupling tolerate?

The specific values depend on the model and design. Generally, it can compensate for radial misalignment of 0.10.3mm, angular misalignment of 12°, and axial displacement of 0.5-1mm. In precision machine tool applications, it is recommended to minimize misalignment to extend service life.

3. Will bellows deformation affect accuracy during high-speed operation?

No. Within the design tolerances, metal bellows have sufficient torsional stiffness and will not significantly deform at rated speed. In fact, their lightweight structure reduces moment of inertia and improves the dynamic response of the machine tool.

4. Does a metal bellows coupling require regular lubrication?

No. Metal bellows couplings are all-metal and have no sliding parts, making them lubrication- and maintenance-free. However, they do require regular inspection for cracks, looseness, or signs of fatigue.